Lower Labor Costs

One of the primary reasons why manufacturing in China is cheaper is due to the country’s lower labor costs. China has a vast pool of skilled and unskilled workers who are willing to work for lower wages compared to their counterparts in developed countries. This is partly due to the lower cost of living in China, which allows workers to maintain a decent standard of living despite earning lower wages.

According to a report by the International Labour Organization (ILO), the average monthly wage for a worker in China’s manufacturing sector was around $876 in 2019, compared to $3,632 in the United States and $4,500 in Germany. The significant difference in labor costs allows companies to save a considerable amount of money on their production expenses when manufacturing in China.

| Country | Average Monthly Wage in Manufacturing (2019) |

|---|---|

| China | $876 |

| United States | $3,632 |

| Germany | $4,500 |

Source: International Labour Organization (ILO)

Lower Raw Material Costs

Another factor that contributes to China’s lower Manufacturing costs is the availability of raw materials at competitive prices. China has an abundant supply of natural resources, such as coal, iron ore, and rare earth elements, which are essential for various manufacturing processes. Additionally, the country has developed an extensive network of suppliers and distributors, which allows manufacturers to source raw materials at lower costs compared to other countries.

China’s government has also invested heavily in infrastructure development, including ports, highways, and railways, which has further reduced transportation costs for raw materials and finished goods. This has made it easier and more cost-effective for manufacturers to access the resources they need to produce their products.

Government Support and Incentives

The Chinese government has played a significant role in promoting the country’s manufacturing sector by providing various support and incentives to businesses. These include tax breaks, subsidies, and preferential policies that encourage companies to set up their manufacturing operations in China.

For example, the government has established numerous special economic zones (SEZs) and industrial parks across the country, which offer lower tax rates, streamlined regulatory processes, and improved infrastructure to attract foreign investment. Additionally, the government has implemented policies to support the development of high-tech industries, such as electronics and aerospace, by providing research and development (R&D) grants and other financial incentives.

Efficient Supply Chain and Infrastructure

China has developed a highly efficient and integrated supply chain that enables manufacturers to produce goods quickly and cost-effectively. The country has a vast network of suppliers, manufacturers, and distributors that work together seamlessly to ensure the smooth flow of goods from raw materials to finished products.

Moreover, China has invested heavily in infrastructure development, including ports, airports, highways, and railways, which has greatly improved the country’s logistics capabilities. This has made it easier and faster for manufacturers to transport goods both within China and to other countries, reducing overall production and distribution costs.

Economies of Scale

China’s massive manufacturing sector allows companies to benefit from economies of scale, which refers to the cost advantages that arise from producing goods in large quantities. As companies increase their production volume, they can spread their fixed costs (such as rent, equipment, and utilities) over a larger number of units, resulting in lower per-unit costs.

Additionally, the concentration of manufacturing activities in China has led to the development of specialized clusters, where companies in related industries are located in close proximity to each other. This allows for greater collaboration, knowledge sharing, and access to a pool of skilled workers, further reducing production costs and improving efficiency.

Technological Advancements and Automation

In recent years, China has made significant investments in technological advancements and automation in the manufacturing sector. The adoption of advanced technologies, such as robotics, artificial intelligence (AI), and the Internet of Things (IoT), has helped manufacturers to improve productivity, reduce labor costs, and enhance product quality.

For example, the use of industrial robots in China’s manufacturing sector has grown rapidly, with the country now accounting for a significant share of the global industrial robot market. According to the International Federation of Robotics (IFR), China installed over 140,000 industrial robots in 2019, representing a 21% increase from the previous year.

| Year | Industrial Robot Installations in China |

|---|---|

| 2018 | 115,000 |

| 2019 | 140,000 |

Source: International Federation of Robotics (IFR)

The adoption of automation and advanced technologies has allowed Chinese manufacturers to remain competitive in the global market by reducing labor costs and improving production efficiency.

Lower Environmental and Safety Regulations

In the past, China’s lower environmental and safety regulations have also contributed to the country’s lower manufacturing costs. Companies operating in China have historically faced less stringent regulations compared to those in developed countries, which has allowed them to reduce costs associated with compliance and waste management.

However, it is important to note that the Chinese government has been making efforts to improve environmental protection and worker safety in recent years. The government has introduced stricter regulations and increased enforcement to address issues such as air and water pollution, as well as workplace safety. While this may lead to a slight increase in manufacturing costs, it is a necessary step towards promoting sustainable and responsible manufacturing practices.

Conclusion

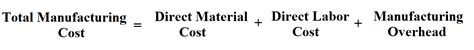

China’s ability to manufacture goods at a lower cost compared to other countries can be attributed to a combination of factors, including lower labor costs, availability of raw materials, government support and incentives, efficient supply chain and infrastructure, economies of scale, technological advancements, and historically lower environmental and safety regulations. These advantages have made China an attractive destination for companies looking to reduce their production costs and remain competitive in the global market.

However, it is important for companies to consider the long-term implications of manufacturing in China, such as the potential impact on product quality, intellectual property protection, and social and environmental responsibility. As China continues to evolve and adapt to changing global demands, businesses must carefully evaluate their manufacturing strategies to ensure sustainable growth and success.

Frequently Asked Questions (FAQ)

-

Q: Will China continue to be the world’s leading manufacturer in the future?

A: While China currently dominates the global manufacturing sector, it is likely to face increasing competition from other countries in the future. As labor costs in China rise and other countries improve their manufacturing capabilities, companies may consider diversifying their production to other regions. However, China’s well-established supply chain, infrastructure, and skilled workforce will continue to make it a strong contender in the manufacturing industry. -

Q: What challenges do companies face when manufacturing in China?

A: Some of the challenges companies may face when manufacturing in China include language and cultural barriers, intellectual property protection issues, quality control concerns, and supply chain disruptions. Additionally, changes in government policies and regulations can also impact manufacturing operations in China. -

Q: How has the US-China trade war affected manufacturing in China?

A: The US-China trade war has led to increased tariffs on goods imported from China, which has raised costs for companies manufacturing in China and exporting to the United States. This has prompted some companies to consider relocating their manufacturing operations to other countries to avoid the higher tariffs. However, many companies still find it advantageous to manufacture in China due to the country’s well-established supply chain and infrastructure. -

Q: What steps is China taking to promote sustainable manufacturing practices?

A: The Chinese government has been implementing various measures to promote sustainable manufacturing practices, such as introducing stricter environmental regulations, investing in renewable energy, and encouraging the adoption of circular economy principles. Additionally, many Chinese manufacturers are voluntarily adopting sustainable practices to meet the growing demand for eco-friendly products and to improve their global reputation. -

Q: How can companies ensure ethical manufacturing practices when producing goods in China?

A: Companies can take several steps to ensure ethical manufacturing practices in China, such as conducting regular audits of their suppliers, implementing strict codes of conduct, and partnering with organizations that promote fair labor practices. Additionally, companies can invest in worker training and development programs to improve working conditions and employee well-being. Transparency and open communication with suppliers and stakeholders are also essential for promoting ethical manufacturing practices.

No responses yet