Understanding PCB traces and Their Composition

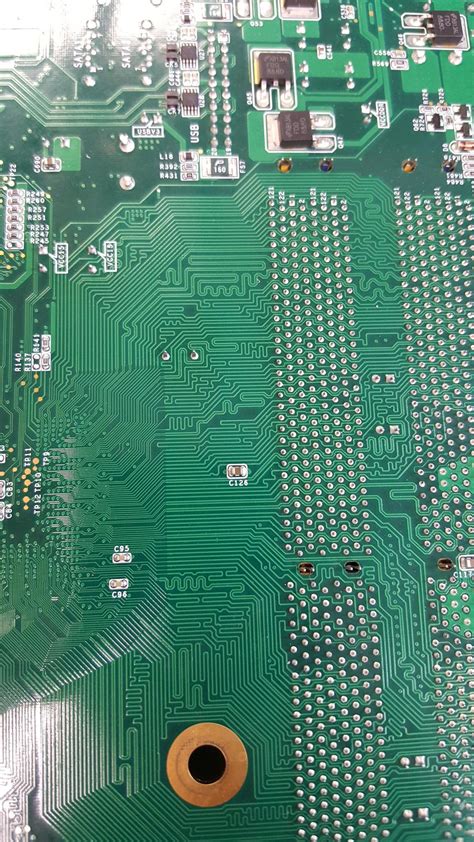

Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a platform for interconnecting various electronic components. One of the critical elements of a PCB is the traces, which are the conductive pathways that carry electrical signals between components. In this article, we will explore the materials used to form these traces and their properties.

What are PCB Traces?

PCB traces are thin, conductive paths etched or printed onto the surface of a PCB. These traces are designed to carry electrical signals and power between the various components mounted on the board. The traces are typically made from a conductive material, such as copper, and are insulated from each other by the PCB substrate material, which is usually a non-conductive laminate.

The Most Common Material for PCB Traces: Copper

Copper is the most widely used material for creating PCB traces due to its excellent electrical conductivity, thermal conductivity, and reliability. Copper traces are formed on the PCB substrate through a process called electroplating or by using a copper-clad laminate.

Electroplated Copper Traces

In the electroplating process, a thin layer of copper is deposited onto the PCB substrate using an electrical current. The process involves the following steps:

- Cleaning the PCB substrate to remove any contaminants

- Applying a conductive seed layer to the substrate

- Immersing the PCB in an electrolytic solution containing copper ions

- Applying an electrical current to attract the copper ions to the seed layer, forming the traces

Electroplated copper traces offer several advantages, such as the ability to create fine pitch traces and the option to control the thickness of the copper layer.

Copper-Clad Laminates

Copper-clad laminates (CCLs) are another popular choice for creating PCB traces. These laminates consist of a non-conductive substrate, such as FR-4, with a thin layer of copper foil bonded to one or both sides. The copper foil is typically 1/8, 1/4, or 1/2 ounce per square foot in thickness, which corresponds to 17.5, 35, or 70 microns, respectively.

To create the traces on a copper-clad laminate, a photoresist layer is applied to the copper foil, and the desired trace pattern is exposed using UV light. The unexposed photoresist is then removed, and the exposed copper is etched away using a chemical solution, leaving behind the desired trace pattern.

Properties of Copper Traces

Copper is an ideal material for PCB traces due to its various properties, which include:

- High electrical conductivity

- Good thermal conductivity

- Excellent solderability

- Resistance to corrosion

- Cost-effectiveness

These properties ensure that copper traces can efficiently carry electrical signals, dissipate heat, and provide reliable connections between components.

Alternative Materials for PCB Traces

While copper is the most common material for PCB traces, there are some alternatives that may be used in specific applications:

Silver

Silver has the highest electrical conductivity of all metals, making it an attractive option for high-frequency applications. However, silver is more expensive than copper and is more prone to oxidation, which can lead to signal degradation over time.

Gold

Gold is sometimes used for PCB traces in high-reliability applications, such as in aerospace or military equipment. Gold is highly resistant to oxidation and corrosion, ensuring signal integrity over a long period. However, gold is significantly more expensive than copper and is not as widely used.

Aluminum

Aluminum is occasionally used as an alternative to copper for PCB traces, particularly in high-power applications. Aluminum has a lower electrical conductivity compared to copper but is lighter and less expensive. However, aluminum is more difficult to solder and is more prone to oxidation, which can affect signal quality.

PCB Trace Thickness and Width

The thickness and width of PCB traces play a crucial role in determining their electrical characteristics and current-carrying capacity. Thicker traces can carry more current and are less susceptible to resistance, while wider traces have lower resistance and can carry signals with less loss.

The thickness of PCB traces is typically measured in ounces of copper per square foot (oz/ft²) or microns (µm). Common thicknesses include:

| Copper Thickness | oz/ft² | Microns (µm) |

|---|---|---|

| 1/8 oz | 0.125 | 17.5 |

| 1/4 oz | 0.25 | 35 |

| 1/2 oz | 0.5 | 70 |

| 1 oz | 1 | 140 |

| 2 oz | 2 | 280 |

The width of PCB traces is determined by the current-carrying requirements and the available space on the PCB. Trace width calculators are often used to determine the appropriate width based on the desired current-carrying capacity, copper thickness, and temperature rise.

Designing PCB Traces for Optimal Performance

To ensure optimal performance and reliability of PCB traces, several design considerations must be taken into account:

- Current-carrying capacity: Traces should be designed to handle the expected current load without excessive heating or voltage drop.

- Signal integrity: Traces should be routed to minimize crosstalk, electromagnetic interference (EMI), and signal reflections.

- Impedance control: Traces should be designed to maintain consistent impedance to prevent signal distortion and reflections, especially in high-frequency applications.

- Manufacturability: Trace width and spacing should adhere to the capabilities of the PCB manufacturing process to ensure reliable production.

By carefully considering these factors and selecting the appropriate materials and dimensions for PCB traces, designers can create reliable and high-performance electronic devices.

Frequently Asked Questions (FAQ)

-

Q: What is the most common material used for PCB traces?

A: Copper is the most widely used material for creating PCB traces due to its excellent electrical conductivity, thermal conductivity, and reliability. -

Q: What are the advantages of using electroplated copper traces?

A: Electroplated copper traces offer several advantages, such as the ability to create fine pitch traces and the option to control the thickness of the copper layer. -

Q: What are copper-clad laminates (CCLs)?

A: Copper-clad laminates (CCLs) are a popular choice for creating PCB traces. They consist of a non-conductive substrate, such as FR-4, with a thin layer of copper foil bonded to one or both sides. -

Q: What are some alternative materials used for PCB traces besides copper?

A: Some alternative materials used for PCB traces include silver, gold, and aluminum. Silver has the highest electrical conductivity but is more expensive and prone to oxidation. Gold is used in high-reliability applications but is significantly more expensive than copper. Aluminum is lighter and less expensive than copper but has lower electrical conductivity and is more difficult to solder. -

Q: What factors should be considered when designing PCB traces for optimal performance?

A: When designing PCB traces for optimal performance, several factors should be considered, including current-carrying capacity, signal integrity, impedance control, and manufacturability. Traces should be designed to handle the expected current load, minimize crosstalk and interference, maintain consistent impedance, and adhere to the capabilities of the PCB manufacturing process.

Conclusion

PCB traces are the backbone of modern electronic devices, providing the necessary interconnections between components. Copper is the most widely used material for creating these traces due to its excellent properties, such as high electrical conductivity, thermal conductivity, and reliability. Alternative materials, such as silver, gold, and aluminum, may be used in specific applications, but copper remains the primary choice for most PCBs.

When designing PCB traces, it is essential to consider factors such as current-carrying capacity, signal integrity, impedance control, and manufacturability to ensure optimal performance and reliability. By carefully selecting the appropriate materials and dimensions for PCB traces, designers can create high-quality, reliable electronic devices that meet the demands of modern applications.

No responses yet