Chemical Composition of Teflon (PTFE)

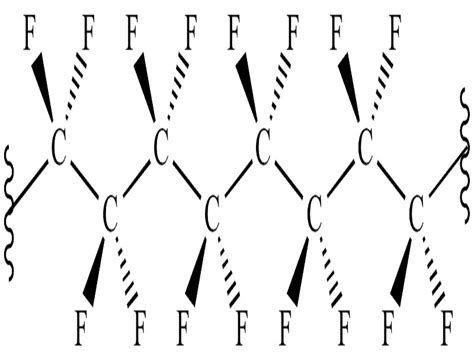

The chemical formula for polytetrafluoroethylene is (C2F4)n, where n is the number of monomer units that make up the polymer chain. Its molecular structure consists of a carbon backbone chain surrounded by fluorine atoms:

F F

| |

–– C – C ––

| |

F F

This unique chemical structure gives Teflon its distinctive properties:

- The strong carbon-fluorine bonds make PTFE very chemically inert and resistant to solvents, acids, and bases.

- The fluorine atoms shield the carbon backbone, creating a very low surface energy that repels water and oil.

- The fluorine atoms are larger than hydrogen atoms, so they shield the carbon-carbon bonds more effectively. This inhibits degradation at high temperatures.

Teflon vs Other Fluoropolymers

While Teflon (PTFE) is the most well-known fluoropolymer, there are several other types with different properties based on their composition:

| Fluoropolymer | Chemical Formula | Properties |

|---|---|---|

| PTFE (Teflon) | (C2F4)n | Highest heat resistance, lowest friction |

| FEP | (C2F4)n(C2H2F2)m | Melt-processable form of PTFE |

| PFA | (C2F4)n(C3F6)m | Similar to FEP with higher melt strength |

| ETFE | (C2H2F2)n | Tougher and more flexible than PTFE |

| ECTFE | (C2H2F2)n(C2HF3)m | Chemically resistant and melt-processable |

| PVDF | (C2H2F2)n | Piezoelectric properties |

The different co-monomers and ratios used produce fluoropolymers with a range of melting points, flexibilities, and chemical resistance properties to suit various applications.

Synthesis of PTFE

PTFE is synthesized via free radical vinyl polymerization of tetrafluoroethylene (TFE) monomer. The TFE monomer is made by pyrolysis of chlorodifluoromethane:

CHClF2 → C2F4 + 2 HCl

The TFE gas is then dissolved in water along with a radical initiator such as persulfate and polymerized at high pressure (up to 100 atm). The TFE monomers join together in a head-to-tail fashion to form the linear PTFE polymer chains:

n C2F4 → (C2F4)n

The PTFE polymer precipitates out of solution as a fine powder which is filtered and dried. This powder can be processed into various shapes through sintering, ram extrusion, or paste extrusion techniques.

Due to the high melt viscosity of PTFE, it cannot be melt processed using standard injection molding or extrusion processes like most thermoplastics. Instead, PTFE parts are made by cold compression molding of the PTFE powder and then sintering at temperatures above its melting point of 327°C.

Properties of Teflon (PTFE)

The unique structure of PTFE results in a combination of useful physical, chemical, thermal, and electrical properties:

Physical Properties

- Low coefficient of friction (0.05-0.10)

- Non-stick surface

- Low surface energy (18.5 mN/m)

- Hydrophobic and oleophobic

- Self-lubricating

- High flexural strength (18-28 MPa)

- High compressive strength (11-12 MPa)

Chemical Properties

- Chemically inert

- Resistant to most solvents, acids, and bases

- Not flammable

Thermal Properties

- Continuous service temperature: -200 to 260°C

- Melting point: 327°C

- Low thermal conductivity (0.25 W/(m·K))

- High thermal expansion (100-160 ppm/°C)

Electrical Properties

- Good dielectric properties

- Low Dielectric constant (2.1 at 1 MHz)

- High dielectric strength (60-173 MV/m)

- High volume resistivity (1016-1018 Ω·m)

Applications of Teflon

The combination of properties exhibited by Teflon make it suitable for use in a wide variety of applications across many industries:

Non-stick Cookware

One of the most well-known uses of Teflon is as a Non-stick coating on pots, pans, and cooking utensils. The low surface energy of PTFE prevents food from sticking and allows for easy cleaning. However, concerns about the safety of Teflon cookware have arisen due to the use of perfluorooctanoic acid (PFOA) in the manufacturing process. PFOA has been linked to health issues and was phased out of use by 2015.

Industrial Coatings

Teflon coatings are used in various industrial applications to reduce friction, prevent sticking, protect against corrosion, or provide electrical insulation. Some examples include:

- Mold release coatings

- Wire and cable insulation

- Gaskets and seals

- Chemical processing equipment

- Bearings and bushings

Medical Devices

The chemical inertness and low friction of Teflon make it biocompatible for use in medical implants and devices such as:

- Vascular grafts

- Hernia meshes

- Catheter guide wires

- Orthopedic implant coatings

- Surgical sutures

Textile Finishes

Teflon fabric protector sprays are used to make textiles water and stain-resistant. The low surface energy finish repels liquids, dirt, and oils, making fabrics easier to clean.

Aerospace Applications

The thermal stability, low friction, and chemical resistance of Teflon are useful for various aerospace components such as:

- Wiring insulation

- Thermal control blankets

- Lubricants for gears and bearings

- Radar-absorbing coatings

Environmental and Health Concerns

While Teflon itself is generally considered non-toxic and safe for use, there have been concerns about the chemicals used in its manufacture, particularly perfluorooctanoic acid (PFOA). PFOA was used as a surfactant in the emulsion polymerization of PTFE up until 2015.

Studies have shown that PFOA can persist in the environment and accumulate in the bodies of humans and animals. Exposure to PFOA has been linked to various health problems including:

- Kidney and testicular cancer

- Thyroid disease

- High cholesterol

- Ulcerative colitis

- Pregnancy-induced hypertension

In response to these concerns, the major manufacturers of PTFE agreed to phase out the use of PFOA in their manufacturing processes by 2015 under the EPA’s PFOA Stewardship Program. Alternative surfactants such as GenX are now used instead, although these are also undergoing further safety testing.

Concerns have also been raised about the use of Teflon in non-stick cookware. When heated to very high temperatures (above 300°C), PTFE coatings can start to break down and release small amounts of toxic gases. However, these temperatures are much higher than those typically used in cooking. It is recommended to avoid overheating Teflon pans, using them on high heat, or leaving them unattended.

Recycling and Disposal

Teflon (PTFE) is not biodegradable and can persist in the environment for a long time if not disposed of properly. However, it can be recycled through a process called sintering. Scrap PTFE can be ground into a powder and then heated and compressed into new shapes.

Some companies have started recycling programs for Teflon products such as non-stick cookware and industrial waste. The coating is stripped off and the PTFE is recovered for recycling.

When disposing of Teflon products in the trash, it is recommended to check with your local waste management authority about any special instructions or restrictions. Incineration of PTFE should be avoided as it can release harmful chemicals.

Frequently Asked Questions

Is Teflon safe to use in cooking?

When used properly, Teflon cookware is generally considered safe. However, it is recommended not to overheat Teflon pans above 500°F (260°C) as this can cause the coating to break down and release fumes. Also avoid using metal utensils that can scratch the coating and potentially cause it to flake off into food.

Does Teflon contain PFOA?

PFOA was previously used in the manufacturing process of Teflon but has been phased out since 2015 due to health concerns. Today’s Teflon products are made using alternative surfactants and are considered PFOA-free.

How long does Teflon last?

The lifespan of a Teflon coating depends on usage and care. With proper use and maintenance, Teflon cookware can last around 3-5 years before the coating starts wearing off. For industrial applications, Teflon coatings may last longer depending on the operating conditions.

Can Teflon be recycled?

Yes, Teflon (PTFE) can be recycled through a sintering process. Some companies have recycling programs for Teflon products. Check with your local waste management authority about recycling options in your area.

What happens if you overheat Teflon?

If heated above 500°F (260°C), Teflon coatings can start to break down and release toxic fumes. These fumes can cause flu-like symptoms in humans and can be fatal to birds. It’s important never to let Teflon cookware overheat or use it under the broiler.

No responses yet