Introduction to Turnkey PCB Assembly

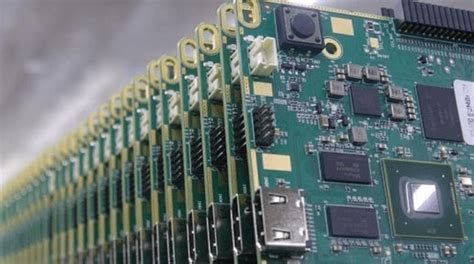

Turnkey PCB (Printed Circuit Board) assembly is a comprehensive manufacturing process that involves the design, fabrication, and assembly of PCBs, all handled by a single provider. This approach streamlines the production process, making it more efficient and cost-effective for businesses and individuals who require high-quality PCBs for their electronic projects.

In this article, we will delve into the details of turnkey PCB Assembly, exploring its benefits, the process involved, and the various applications of PCBs in today’s technology-driven world.

The Benefits of Turnkey PCB Assembly

1. Streamlined Production Process

One of the primary advantages of turnkey PCB assembly is the streamlined production process. By entrusting the entire PCB manufacturing process to a single provider, you can eliminate the need to coordinate with multiple vendors for different stages of production. This simplifies the logistics and reduces the risk of miscommunication or delays.

2. Cost-Effectiveness

Turnkey PCB assembly can be more cost-effective than managing each stage of the production process separately. By bundling the design, fabrication, and assembly services, providers can offer competitive pricing and volume discounts. Additionally, the streamlined process reduces the overall lead time, which can result in lower inventory costs and faster time-to-market for your products.

3. Quality Assurance

Reputable turnkey PCB assembly providers adhere to strict quality control measures throughout the production process. They employ experienced engineers and technicians who follow industry standards and best practices to ensure that your PCBs meet the highest quality standards. This attention to detail minimizes the risk of defects and ensures the reliability and performance of your electronic products.

4. Access to Expertise and Technology

Turnkey PCB assembly providers invest in state-of-the-art equipment and employ skilled professionals with expertise in PCB design, fabrication, and assembly. By partnering with a turnkey provider, you gain access to their knowledge and resources, which can be particularly beneficial if you lack in-house expertise or specialized equipment.

The Turnkey PCB Assembly Process

The turnkey PCB assembly process typically involves the following stages:

-

PCB Design: The process begins with the design of the PCB. The provider’s engineering team works closely with you to understand your requirements and create a PCB layout that meets your specifications. They use advanced design software to ensure optimal component placement, signal integrity, and manufacturability.

-

PCB fabrication: Once the design is finalized, the PCB is fabricated using high-quality materials and advanced manufacturing techniques. This stage involves creating the copper traces, drilling holes, applying Solder Mask, and adding silkscreen legends to the PCB.

-

Component Sourcing: The turnkey provider sources the necessary components for your PCB assembly. They have established relationships with reliable component suppliers and can often procure components at competitive prices.

-

PCB Assembly: The fabricated PCB and sourced components are then assembled using automated equipment and skilled technicians. The assembly process includes solder paste application, component placement, and Reflow Soldering.

-

Inspection and Testing: After assembly, the PCBs undergo rigorous inspection and testing to ensure their functionality and quality. This may include Automated Optical Inspection (AOI), X-ray inspection, in-circuit testing (ICT), and functional testing.

-

Packaging and Shipping: Once the PCBs have passed all quality checks, they are packaged securely and shipped to your specified location.

Applications of Turnkey PCB Assembly

Turnkey PCB assembly finds applications in various industries and sectors, including:

-

Consumer Electronics: PCBs are the backbone of modern consumer electronics, such as smartphones, tablets, laptops, and smart home devices.

-

Automotive Industry: PCBs play a crucial role in automotive electronics, powering infotainment systems, engine control units, and advanced driver assistance systems (ADAS).

-

Medical Devices: Medical equipment relies on high-quality PCBs for precise and reliable operation. Turnkey PCB assembly is essential for producing medical-grade electronics.

-

Industrial Automation: PCBs are integral to industrial automation systems, controlling machinery, sensors, and communication networks.

-

Aerospace and Defense: The aerospace and defense sectors require robust and reliable PCBs that can withstand extreme conditions and meet stringent safety standards.

-

Internet of Things (IoT): The growing IoT ecosystem heavily relies on PCBs for connecting devices, sensors, and gateways.

Factors to Consider When Choosing a Turnkey PCB Assembly Provider

When selecting a turnkey PCB assembly provider, consider the following factors:

-

Experience and Expertise: Look for a provider with a proven track record and extensive experience in PCB assembly. They should have a team of skilled engineers and technicians who can handle complex projects and provide valuable insights.

-

Quality Standards: Ensure that the provider adheres to industry quality standards, such as IPC (Association Connecting Electronics Industries) standards. They should have a robust quality management system in place to minimize defects and ensure consistent performance.

-

Technology and Equipment: Inquire about the provider’s manufacturing capabilities and the equipment they use. Modern facilities with advanced technology can offer higher precision, faster turnaround times, and better quality control.

-

Customer Support: Choose a provider that offers excellent customer support throughout the production process. They should be responsive to your inquiries, provide regular updates, and address any concerns promptly.

-

Pricing and Lead Times: Compare pricing and lead times from multiple providers to find the best value for your needs. However, be cautious of extremely low prices, as they may compromise quality or reliability.

Frequently Asked Questions (FAQ)

-

Q: What is the minimum order quantity (MOQ) for turnkey PCB assembly?

A: MOQs vary among providers, but many offer low-volume production options for prototyping and small-scale projects. Some providers may have MOQs as low as 1 or 10 units, while others may require higher quantities for cost-effective production. -

Q: How long does the turnkey PCB assembly process take?

A: The lead time for turnkey PCB assembly depends on various factors, such as the complexity of the design, the availability of components, and the production volume. Typical lead times range from a few days to several weeks. Rush services may be available for time-sensitive projects, but they often come at a premium cost. -

Q: Can I provide my own components for turnkey PCB assembly?

A: Yes, most turnkey PCB assembly providers offer the option of consigned parts, where you can supply your own components for assembly. However, ensure that the components meet the required specifications and are available in sufficient quantities to avoid delays. -

Q: What file formats are required for PCB design submission?

A: The most common file formats for PCB design submission include Gerber files (RS-274X), ODB++ (Open Database), and IPC-2581. Your turnkey provider will specify their preferred file formats and any additional requirements for design submission. -

Q: How can I ensure the confidentiality of my PCB design and intellectual property?

A: Reputable turnkey PCB assembly providers understand the importance of protecting their clients’ intellectual property. They often have non-disclosure agreements (NDAs) in place to safeguard your design and confidential information. If you have specific security concerns, discuss them with your provider and establish clear confidentiality terms.

Conclusion

Turnkey PCB assembly offers a comprehensive and efficient solution for businesses and individuals seeking high-quality PCBs for their electronic projects. By streamlining the production process, turnkey assembly reduces costs, improves quality control, and provides access to expertise and advanced technology.

When selecting a turnkey PCB assembly provider, consider factors such as experience, quality standards, manufacturing capabilities, customer support, pricing, and lead times. By partnering with a reliable and reputable provider, you can ensure the success of your electronic products and bring your ideas to life.

As the demand for advanced electronics continues to grow across various industries, turnkey PCB assembly will play an increasingly important role in enabling innovation and driving technological progress.

| Industry | Applications of Turnkey PCB Assembly |

|---|---|

| Consumer Electronics | Smartphones, tablets, laptops, smart home devices |

| Automotive Industry | Infotainment systems, engine control units, ADAS |

| Medical Devices | Medical-grade electronics for precise and reliable operation |

| Industrial Automation | Control systems for machinery, sensors, and communication networks |

| Aerospace and Defense | Robust and reliable PCBs for extreme conditions and safety standards |

| Internet of Things | Connecting devices, sensors, and gateways in the growing IoT ecosystem |

This table provides a visual representation of the various industries and applications that benefit from turnkey PCB assembly, highlighting the versatility and importance of this manufacturing approach in today’s technology-driven world.

No responses yet