Understanding FR4 and its properties

FR4 is a composite material consisting of a woven fiberglass fabric impregnated with an epoxy resin. This combination of materials provides excellent mechanical strength, electrical insulation, and thermal stability. FR4 is known for its flame-retardant properties, hence the “FR” in its name, which stands for “Flame Retardant.”

Composition of FR4

The primary components of FR4 are:

-

Fiberglass fabric: The woven fiberglass fabric acts as a reinforcement, providing mechanical strength and dimensional stability to the material.

-

Epoxy resin: The epoxy resin is a thermosetting polymer that binds the fiberglass fabric together and provides electrical insulation and chemical resistance.

Advantages of using FR4

FR4 offers several advantages that make it a popular choice for PCBs and other electronic applications:

-

High mechanical strength: The combination of fiberglass and epoxy resin provides excellent mechanical strength, making FR4 suitable for applications that require durability and resistance to physical stress.

-

Excellent electrical insulation: FR4 has a high dielectric strength, which means it can withstand high voltages without breaking down or allowing current to pass through.

-

Thermal stability: FR4 maintains its mechanical and electrical properties over a wide temperature range, making it suitable for use in various environmental conditions.

-

Flame retardancy: The epoxy resin used in FR4 is formulated to be flame-retardant, which helps prevent the spread of fire in case of an electrical fault or overheating.

Thermal rating of FR4

The thermal rating of FR4 is a measure of its ability to withstand high temperatures without degrading or losing its properties. It is an essential parameter to consider when designing electronic devices, as it determines the material’s suitability for specific applications and operating conditions.

Glass transition temperature (Tg)

The glass transition temperature (Tg) is a critical property that influences the thermal rating of FR4. At temperatures below Tg, the material is rigid and maintains its mechanical and electrical properties. However, as the temperature rises above Tg, the material begins to soften and loses its structural integrity.

The Tg of standard FR4 is approximately 130°C to 140°C (266°F to 284°F). This means that FR4 can maintain its properties up to these temperatures, making it suitable for most consumer electronics applications.

Continuous operating temperature (COT)

The continuous operating temperature (COT) is the maximum temperature at which FR4 can be used continuously without significant degradation of its properties. The COT of standard FR4 is typically around 130°C (266°F), which is slightly lower than its Tg.

It is essential to keep the operating temperature of electronic devices below the COT of FR4 to ensure long-term reliability and prevent material degradation.

Factors affecting the thermal rating of FR4

Several factors can influence the thermal rating of FR4, including:

-

Resin formulation: The type and composition of the epoxy resin used in FR4 can affect its thermal properties. Some specialized FR4 formulations, such as high Tg FR4, offer improved thermal performance compared to standard FR4.

-

Thickness: The thickness of the FR4 material can impact its thermal performance. Thicker FR4 laminates generally have better thermal stability and can withstand higher temperatures than thinner laminates.

-

Copper weight: The amount of copper used in the PCB can also affect the thermal rating of FR4. Higher copper weights can help dissipate heat more effectively, improving the overall thermal performance of the PCB.

-

Environmental factors: Exposure to moisture, chemicals, and other environmental factors can degrade the thermal properties of FR4 over time. Proper protective coatings and enclosures can help mitigate these effects.

High Tg FR4 for improved thermal performance

For applications that require higher thermal ratings, high Tg FR4 materials are available. These specialized FR4 formulations have a higher glass transition temperature, typically ranging from 170°C to 180°C (338°F to 356°F), and a higher continuous operating temperature, around 160°C (320°F).

High Tg FR4 is used in applications that demand better thermal stability and reliability, such as:

-

Automotive electronics: The harsh environmental conditions and high operating temperatures in automotive applications often require the use of high Tg FR4.

-

Aerospace and defense: The stringent reliability requirements and exposure to extreme temperatures in aerospace and defense applications make high Tg FR4 a suitable choice.

-

High-power electronics: Electronic devices that generate significant amounts of heat, such as power converters and amplifiers, can benefit from the improved thermal performance of high Tg FR4.

Thermal management strategies for FR4-based PCBs

In addition to selecting the appropriate FR4 material based on its thermal rating, several thermal management strategies can be employed to ensure the reliable operation of electronic devices:

-

Adequate cooling: Incorporating heat sinks, fans, or other cooling solutions can help dissipate heat generated by electronic components, keeping the operating temperature within the acceptable range for FR4.

-

Proper component placement: Strategically placing heat-generating components on the PCB can help distribute heat more evenly and prevent localized hot spots that could exceed the thermal rating of FR4.

-

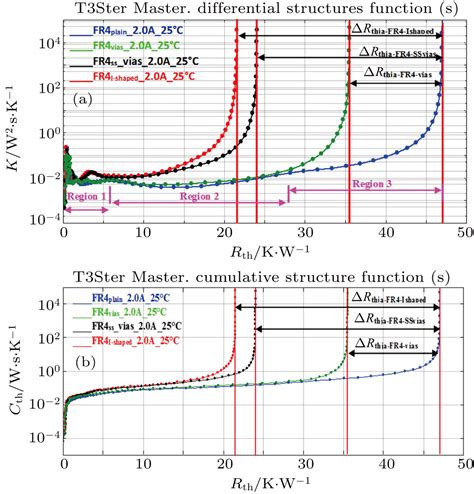

Thermal vias: Using thermal vias, which are small holes filled with conductive material, can help transfer heat from the PCB surface to the inner layers or to an external heat sink, improving overall thermal performance.

-

Thermal interface materials: Applying thermal interface materials, such as thermal pads or thermal adhesives, between components and the PCB can enhance heat transfer and reduce thermal resistance.

FAQs

- What is the thermal rating of standard FR4?

-

The glass transition temperature (Tg) of standard FR4 is approximately 130°C to 140°C (266°F to 284°F), and its continuous operating temperature (COT) is typically around 130°C (266°F).

-

Can FR4 be used in high-temperature applications?

-

Standard FR4 is suitable for most consumer electronics applications. However, for high-temperature applications, high Tg FR4 materials with improved thermal performance are available, offering a Tg of 170°C to 180°C (338°F to 356°F) and a COT of around 160°C (320°F).

-

How does the thickness of FR4 affect its thermal rating?

-

Thicker FR4 laminates generally have better thermal stability and can withstand higher temperatures than thinner laminates. This is because thicker materials have a higher thermal mass and are less susceptible to rapid temperature changes.

-

What are some thermal management strategies for FR4-based PCBs?

-

Thermal management strategies for FR4-based PCBs include adequate cooling (heat sinks, fans), proper component placement, the use of thermal vias, and the application of thermal interface materials.

-

Can environmental factors affect the thermal rating of FR4?

- Yes, exposure to moisture, chemicals, and other environmental factors can degrade the thermal properties of FR4 over time. Proper protective coatings and enclosures can help mitigate these effects and maintain the material’s thermal performance.

Thermal Rating Range of FR4:

| FR4 Type | Glass Transition Temperature (Tg) | Continuous Operating Temperature (COT) |

|———-|———————————–|—————————————-|

| Standard FR4 | 130°C to 140°C (266°F to 284°F) | 130°C (266°F) |

| High Tg FR4 | 170°C to 180°C (338°F to 356°F) | 160°C (320°F) |

In conclusion, understanding the thermal rating of FR4 is essential for designing reliable and durable electronic devices. The glass transition temperature (Tg) and continuous operating temperature (COT) are key parameters that determine the thermal performance of FR4. While standard FR4 is suitable for most consumer electronics applications, high Tg FR4 materials offer improved thermal stability for more demanding applications. By selecting the appropriate FR4 material and implementing effective thermal management strategies, designers can ensure the optimal performance and longevity of their electronic products.

No responses yet