Introduction to PCB Thickness

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide the physical support and electrical connections for electronic components. One crucial aspect of PCB design is the thickness of the board. PCB thickness is typically measured in mils, with one mil equal to 1/1000th of an inch.

The standard thickness of a PCB can vary depending on the specific application and design requirements. However, some common thicknesses have emerged as industry standards. Understanding these standard thicknesses is essential for designers, manufacturers, and anyone working with PCBs.

Common PCB Thickness Standards

1. 1.6mm (63 mil)

One of the most common PCB thicknesses is 1.6mm, which translates to approximately 63 mil. This thickness is widely used in many applications, including:

- Consumer electronics

- Telecommunications equipment

- Industrial control systems

The 1.6mm thickness provides a good balance between durability and flexibility. It is thick enough to support larger components and withstand moderate mechanical stress but thin enough to allow for some flexibility in the board.

2. 1.0mm (39 mil)

Another standard PCB thickness is 1.0mm, or about 39 mil. This thinner board is often used in applications where space is limited, such as:

- Mobile devices

- Wearable electronics

- High-density designs

The 1.0mm thickness allows for more compact designs and can help reduce the overall size and weight of the device. However, the thinner board may be more susceptible to damage from mechanical stress or vibration.

3. 2.0mm (79 mil)

On the thicker end of the spectrum, 2.0mm (79 mil) PCBs are used in applications that require greater durability and mechanical strength. Some common uses include:

- Power electronics

- Automotive systems

- Heavy-duty industrial equipment

The thicker board can better support heavier components and withstand more intense mechanical stress and vibration. However, the increased thickness can also make the board less flexible and more difficult to work with in some cases.

Factors Affecting PCB Thickness Choice

When choosing the appropriate PCB thickness for a project, several factors must be considered:

1. Component Size and Weight

The size and weight of the components that will be mounted on the PCB play a significant role in determining the required thickness. Heavier or larger components may require a thicker board for proper support.

2. Mechanical Stress and Vibration

The expected level of mechanical stress and vibration the PCB will be subjected to should also be considered. Applications exposed to higher levels of stress or vibration may benefit from thicker boards to improve durability.

3. Space Constraints

In some cases, the available space for the PCB may dictate the thickness choice. Thinner boards may be necessary to fit into tight spaces or to reduce the overall size of the device.

4. Manufacturing Capabilities

The manufacturing capabilities of the PCB fabricator can also influence the thickness choice. Some manufacturers may have limitations on the minimum or maximum thicknesses they can produce reliably.

PCB Thickness Tolerance

When specifying PCB thickness, it’s important to consider the acceptable tolerance range. The actual thickness of the manufactured board may vary slightly from the nominal value due to process variations.

Typical PCB thickness tolerances are:

| Nominal Thickness | Tolerance |

|---|---|

| 1.0mm (39 mil) | ± 10% |

| 1.6mm (63 mil) | ± 10% |

| 2.0mm (79 mil) | ± 10% |

It’s crucial to ensure that the tolerance range is acceptable for the specific application and that the design can accommodate any potential variations in thickness.

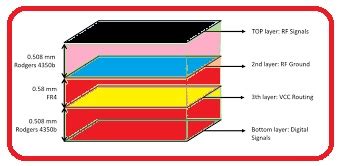

Multilayer PCBs and Thickness Considerations

Multilayer PCBs, which consist of multiple layers of conductive material separated by insulating layers, introduce additional thickness considerations.

The thickness of a multilayer PCB is determined by several factors:

- The number of layers

- The thickness of each layer

- The thickness of the insulating material between layers

As the number of layers increases, so does the overall thickness of the board. However, using thinner individual layers can help minimize the total thickness.

Common layer thicknesses for multilayer PCBs include:

| Layer Type | Typical Thickness |

|---|---|

| Outer layers | 1oz (35μm) |

| Inner layers | 0.5oz (18μm) |

The insulating material between layers, typically FR-4, also contributes to the overall thickness. The standard thickness for the insulating layers is usually around 0.2mm (8 mil).

When designing multilayer PCBs, it’s essential to work closely with the PCB fabricator to ensure that the desired thickness can be achieved while maintaining the required electrical and mechanical properties.

FAQ

1. What is the most common PCB thickness?

The most common PCB thickness is 1.6mm (63 mil). This thickness provides a good balance between durability and flexibility for a wide range of applications.

2. Can I use a thinner PCB to save space?

Yes, thinner PCBs, such as 1.0mm (39 mil), can be used to save space in applications where size is a critical factor. However, thinner boards may be more susceptible to mechanical stress and damage.

3. What factors should I consider when choosing PCB thickness?

When choosing PCB thickness, consider the size and weight of the components, the expected level of mechanical stress and vibration, space constraints, and the manufacturing capabilities of the PCB fabricator.

4. How does PCB thickness affect the cost?

Generally, thicker PCBs are more expensive to manufacture due to the increased material usage and processing time. However, the cost difference between common thicknesses like 1.6mm and 1.0mm may not be significant for most applications.

5. Can I mix different thicknesses in the same PCB?

In some cases, it may be possible to mix different thicknesses in the same PCB, such as using a thicker section for heavy components and a thinner section for space-constrained areas. However, this can complicate the manufacturing process and increase costs. It’s best to consult with your PCB fabricator to determine the feasibility of mixing thicknesses.

Conclusion

Understanding the standard thicknesses of PCBs in mil is crucial for anyone involved in PCB design or manufacturing. The most common thicknesses, such as 1.6mm (63 mil), 1.0mm (39 mil), and 2.0mm (79 mil), serve different purposes and have their own advantages and limitations.

When selecting the appropriate PCB thickness, it’s essential to consider factors such as component size and weight, mechanical stress and vibration, space constraints, and manufacturing capabilities. Additionally, multilayer PCBs introduce further thickness considerations, with the number of layers, individual layer thickness, and insulating material all contributing to the overall thickness.

By working closely with PCB fabricators and taking into account the specific requirements of the application, designers can choose the optimal PCB thickness to ensure the best performance, reliability, and cost-effectiveness for their projects.

No responses yet