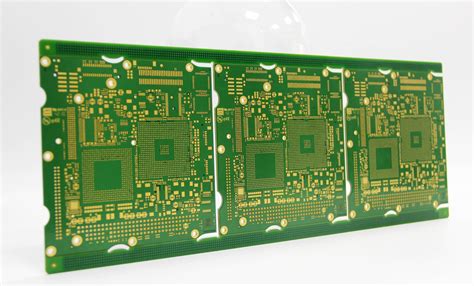

Understanding PCB materials

PCB materials are the substrates used to fabricate printed circuit boards. They provide mechanical support and electrical insulation for the conductive traces and components mounted on the board. The selection of the appropriate PCB material depends on various factors, including the intended application, operating environment, frequency range, and manufacturing process.

Composition of PCB Materials

PCB materials are typically composed of a dielectric substrate, which is an insulating material, and a conductive layer, usually copper, laminated onto one or both sides of the substrate. The dielectric substrate determines the electrical and thermal properties of the PCB, while the copper layer provides the conductive paths for electrical signals.

Properties of PCB Materials

When choosing a PCB material, several key properties need to be considered:

-

Dielectric Constant (Dk): The dielectric constant represents the material’s ability to store electrical energy. It affects the speed of signal propagation and the characteristic impedance of the PCB traces.

-

Dissipation Factor (Df): The dissipation factor measures the energy loss in the dielectric material. A lower dissipation factor indicates lower signal loss and better performance at high frequencies.

-

Thermal Conductivity: Thermal conductivity determines the material’s ability to dissipate heat generated by the components mounted on the PCB. Higher thermal conductivity helps in maintaining stable operating temperatures.

-

Coefficient of Thermal Expansion (CTE): CTE refers to the material’s expansion or contraction with changes in temperature. A PCB material with a CTE close to that of the mounted components reduces stress and improves reliability.

-

Mechanical Strength: The mechanical strength of the PCB material affects its ability to withstand physical stress during manufacturing, assembly, and operation.

Standard PCB Material: FR-4

FR-4 (Flame Retardant 4) is the most widely used and standard PCB material in the electronics industry. It is a composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. FR-4 offers a balanced combination of electrical, mechanical, and thermal properties, making it suitable for a wide range of applications.

Composition of FR-4

FR-4 is manufactured by layering sheets of woven fiberglass cloth and impregnating them with an epoxy resin. The fiberglass provides mechanical strength and dimensional stability, while the epoxy resin acts as a binder and offers electrical insulation properties. The number of layers and the thickness of the FR-4 laminate can be varied to meet specific application requirements.

Properties of FR-4

FR-4 exhibits the following key properties:

| Property | Value |

|---|---|

| Dielectric Constant (Dk) | 4.2 – 4.9 (at 1 MHz) |

| Dissipation Factor (Df) | 0.02 (at 1 MHz) |

| Thermal Conductivity | 0.25 – 0.3 W/m·K |

| Coefficient of Thermal Expansion (CTE) | 12 – 16 ppm/°C |

| Tensile Strength | 310 – 380 MPa |

| Flexural Strength | 415 – 485 MPa |

These properties make FR-4 suitable for a wide range of applications, including consumer electronics, telecommunications, automotive, and industrial equipment.

Advantages of FR-4

FR-4 offers several advantages as a PCB material:

-

Versatility: FR-4 is compatible with various manufacturing processes, including standard and advanced PCB fabrication techniques.

-

Cost-effectiveness: FR-4 is relatively inexpensive compared to other PCB materials, making it a cost-effective choice for many applications.

-

Availability: FR-4 is widely available and has a well-established supply chain, ensuring a reliable and consistent supply of the material.

-

Flame Retardancy: The epoxy resin used in FR-4 is flame retardant, making it suitable for applications that require compliance with fire safety standards.

Limitations of FR-4

While FR-4 is a versatile and widely used PCB material, it has some limitations:

-

High-Frequency Performance: FR-4 has higher dielectric losses compared to some specialized PCB materials, which can limit its performance at high frequencies (above 2 GHz).

-

Thermal Management: FR-4 has a relatively low thermal conductivity, which can lead to heat buildup in high-power applications. Additional thermal management techniques may be required.

-

Moisture Absorption: FR-4 can absorb moisture, which can affect its electrical and mechanical properties. Proper storage and handling procedures are necessary to minimize moisture absorption.

Other PCB Materials

While FR-4 is the standard PCB material, there are other materials available for specific applications or performance requirements. Some common alternative PCB materials include:

High-Frequency Materials

For applications operating at high frequencies (above 2 GHz), specialized PCB materials with lower dielectric losses and more stable properties are used. Examples include:

-

Rogers RO4000 series: These materials offer low dielectric constant and low loss tangent, making them suitable for high-frequency applications such as wireless communication and radar systems.

-

PTFE (Polytetrafluoroethylene): PTFE-based materials, such as Rogers RT/duroid, provide excellent high-frequency performance and are used in microwave and RF applications.

High-Temperature Materials

In applications exposed to high temperatures, PCB materials with higher glass transition temperatures (Tg) and better thermal stability are required. Examples include:

-

Polyimide: Polyimide-based materials, such as DuPont Kapton, offer excellent thermal stability and can withstand temperatures up to 400°C.

-

Ceramic-based materials: Alumina and aluminum nitride (AlN) are ceramic-based PCB materials that provide excellent thermal conductivity and high-temperature stability.

Flexible Materials

Flexible PCBs require materials that can withstand bending and flexing without cracking or losing their electrical properties. Examples include:

-

Polyimide: Polyimide films, such as DuPont Kapton, are commonly used for flexible PCBs due to their excellent mechanical and electrical properties.

-

Polyester: Polyester-based materials, such as DuPont Mylar, are used for low-cost and less demanding flexible PCB applications.

PCB Material Selection Considerations

When selecting a PCB material for a specific application, several factors need to be considered:

-

Frequency Range: The operating frequency range of the application determines the required dielectric properties of the PCB material. High-frequency applications may require specialized materials with lower dielectric losses.

-

Operating Environment: The environmental conditions, such as temperature, humidity, and chemical exposure, influence the choice of PCB material. Materials with appropriate thermal stability, moisture resistance, and chemical compatibility should be selected.

-

Cost: The cost of the PCB material is an important consideration, especially for high-volume production. A balance between performance and cost-effectiveness should be achieved.

-

Manufacturing Process: The selected PCB material should be compatible with the intended manufacturing processes, such as drilling, etching, and soldering.

-

Compliance with Standards: The PCB material should meet the relevant industry standards and regulations, such as UL (Underwriters Laboratories) and RoHS (Restriction of Hazardous Substances).

Frequently Asked Questions (FAQ)

-

What is the most commonly used PCB material?

FR-4 (Flame Retardant 4) is the most commonly used and standard PCB material in the electronics industry. It offers a good balance of electrical, mechanical, and thermal properties, making it suitable for a wide range of applications. -

Can FR-4 be used for high-frequency applications?

FR-4 can be used for high-frequency applications up to a certain limit (usually around 2 GHz). For applications operating at higher frequencies, specialized PCB materials with lower dielectric losses, such as Rogers RO4000 series or PTFE-based materials, are recommended. -

What is the difference between FR-4 and polyimide PCB materials?

FR-4 is a glass-reinforced epoxy laminate, while polyimide is a high-performance polymer material. Polyimide offers better thermal stability and flexibility compared to FR-4. It is commonly used in applications that require high-temperature resistance or flexible PCBs. -

How does the dielectric constant affect PCB performance?

The dielectric constant (Dk) of a PCB material affects the speed of signal propagation and the characteristic impedance of the PCB traces. A lower dielectric constant results in faster signal propagation and lower capacitance, which is desirable for high-frequency applications. -

What factors should be considered when selecting a PCB material for a specific application?

When selecting a PCB material, factors such as the operating frequency range, environmental conditions, cost, manufacturing process, and compliance with industry standards should be considered. The material should provide the necessary electrical, mechanical, and thermal properties to meet the specific requirements of the application.

Conclusion

The choice of PCB material is crucial for the performance, reliability, and cost-effectiveness of electronic devices. FR-4 is the standard and most widely used PCB material, offering a good balance of properties for a wide range of applications. However, for specific requirements such as high-frequency operation, high-temperature exposure, or flexibility, alternative materials like high-frequency laminates, polyimide, or flexible substrates may be more suitable.

When selecting a PCB material, it is essential to consider factors such as the operating frequency range, environmental conditions, cost, manufacturing process, and compliance with industry standards. By understanding the properties and characteristics of different PCB materials, designers and manufacturers can make informed decisions to ensure optimal performance and reliability of their electronic products.

As technology advances and new applications emerge, the development of advanced PCB materials with enhanced properties will continue to drive innovation in the electronics industry. Staying updated with the latest advancements in PCB materials and their capabilities will enable engineers and manufacturers to design and produce cutting-edge electronic devices that meet the ever-increasing demands of the market.

No responses yet