What is Relative Permittivity?

Relative permittivity (εᵣ) is a dimensionless quantity that describes the ability of a material to store electrical energy in an electric field. It is the ratio of the material’s absolute permittivity (ε) to the permittivity of vacuum (ε₀). The relative permittivity of a material determines how much the electric field is reduced within the material compared to vacuum.

εᵣ = ε / ε₀

where:

– εᵣ is the relative permittivity (dimensionless)

– ε is the absolute permittivity of the material (F/m)

– ε₀ is the permittivity of vacuum (8.85 × 10⁻¹² F/m)

Importance of Relative Permittivity in PCB Design

In PCB design, the relative permittivity of the substrate material, such as FR4, plays a crucial role in determining the following aspects:

-

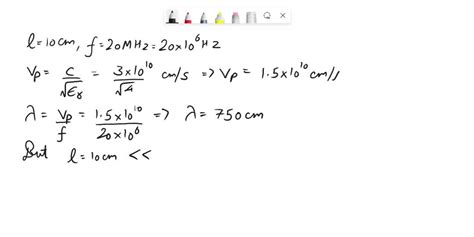

Signal propagation speed: The speed at which signals travel through the PCB is inversely proportional to the square root of the relative permittivity. A higher relative permittivity results in slower signal propagation.

-

Characteristic impedance: The characteristic impedance of a transmission line on a PCB is directly proportional to the square root of the relative permittivity. A higher relative permittivity leads to a lower characteristic impedance.

-

Capacitance: The capacitance between conductors on a PCB is directly proportional to the relative permittivity of the substrate material. A higher relative permittivity results in higher capacitance.

-

Crosstalk: The relative permittivity of the substrate material affects the coupling capacitance between adjacent traces, which can contribute to crosstalk. A higher relative permittivity increases the risk of crosstalk.

Relative Permittivity of FR4

FR4 is a composite material made of woven fiberglass cloth impregnated with an epoxy resin binder. The relative permittivity of FR4 is not a constant value and can vary depending on several factors, such as the specific formulation of the material, frequency, and temperature.

Typical Values of Relative Permittivity for FR4

The relative permittivity of FR4 typically ranges from 4.2 to 4.8 at room temperature and low frequencies (< 1 GHz). However, it is essential to consult the manufacturer’s datasheet for the specific FR4 material being used, as the exact value may vary.

Here is a table summarizing the typical relative permittivity values for FR4:

| Frequency Range | Relative Permittivity (εᵣ) |

|---|---|

| < 1 GHz | 4.2 to 4.8 |

| 1 GHz to 10 GHz | 4.1 to 4.7 |

| > 10 GHz | 4.0 to 4.6 |

It is important to note that these values are approximate and can vary depending on the specific FR4 formulation and environmental conditions.

Factors Affecting the Relative Permittivity of FR4

Several factors can influence the relative permittivity of FR4:

-

Frequency: The relative permittivity of FR4 decreases slightly with increasing frequency. This is due to the frequency-dependent nature of the polarization mechanisms within the material.

-

Temperature: The relative permittivity of FR4 increases with increasing temperature. This is because the molecular motion within the material becomes more pronounced at higher temperatures, leading to increased polarization.

-

Moisture content: The presence of moisture in FR4 can increase its relative permittivity. Moisture absorption occurs due to the hydrophilic nature of the epoxy resin and the presence of polar groups in the material.

-

Filler content: The type and amount of fillers used in the FR4 formulation can affect its relative permittivity. Fillers with a higher dielectric constant will increase the overall relative permittivity of the composite material.

Measurement Techniques for Relative Permittivity

There are several methods for measuring the relative permittivity of FR4 and other dielectric materials. Some common techniques include:

-

Parallel plate capacitor method: This method involves sandwiching a sample of the material between two parallel conductive plates and measuring the capacitance. The relative permittivity can be calculated from the measured capacitance, plate area, and sample thickness.

-

Transmission line method: In this method, a sample of the material is placed in a transmission line (e.g., a coaxial line or waveguide), and the complex permittivity is extracted from the measured scattering parameters (S-parameters).

-

Resonant cavity method: This technique involves placing a sample of the material in a resonant cavity and measuring the shift in the resonant frequency and quality factor. The relative permittivity can be determined from these measurements and the cavity dimensions.

-

Time-domain reflectometry (TDR): TDR is a technique that measures the reflections of a voltage step or pulse sent through a transmission line. By analyzing the reflected waveform, the relative permittivity of the material can be determined.

Impact of Relative Permittivity on PCB Performance

The relative permittivity of FR4 has a significant impact on the performance of PCBs, particularly at high frequencies. Understanding these effects is crucial for designing reliable and high-performance electronic systems.

Signal Integrity

Signal integrity refers to the ability of a PCB to maintain the quality and fidelity of signals as they propagate through the board. The relative permittivity of FR4 affects signal integrity in several ways:

-

Signal delay: A higher relative permittivity results in slower signal propagation speeds, which can lead to increased signal delays. This is particularly important for high-speed digital circuits, where timing is critical.

-

Impedance control: The characteristic impedance of a transmission line on a PCB is affected by the relative permittivity of the substrate material. Proper impedance control is essential for minimizing reflections and ensuring good signal quality.

-

Dispersion: The frequency-dependent nature of the relative permittivity can cause dispersion, where different frequency components of a signal travel at slightly different speeds. This can lead to signal distortion and limit the bandwidth of the system.

Power Integrity

Power integrity refers to the ability of a PCB to provide a stable and clean power supply to the components mounted on it. The relative permittivity of FR4 can impact power integrity in the following ways:

-

Decoupling capacitance: The relative permittivity of FR4 affects the value of decoupling capacitors needed to suppress power supply noise. A higher relative permittivity allows for smaller capacitor values, but it also increases the capacitive coupling between power and ground planes.

-

Power plane resonances: The relative permittivity of FR4 influences the resonant frequencies of power and ground planes. These resonances can lead to voltage fluctuations and increased power supply noise.

Electromagnetic Compatibility (EMC)

Electromagnetic compatibility (EMC) is the ability of a PCB to function properly in its electromagnetic environment without causing or being susceptible to electromagnetic interference. The relative permittivity of FR4 can affect EMC in the following ways:

-

Crosstalk: A higher relative permittivity increases the coupling capacitance between adjacent traces, which can lead to increased crosstalk. This can cause signal integrity issues and compromise EMC.

-

Radiated emissions: The relative permittivity of FR4 affects the wavelength of signals in the material, which can impact the antenna-like behavior of traces and planes. This can influence the radiated emissions from the PCB.

Design Considerations for FR4 PCBs

When designing PCBs using FR4 substrate material, several factors should be considered to ensure optimal performance and reliability:

-

Material selection: Choose an FR4 material with a relative permittivity that is suitable for the intended application and frequency range. Consult the manufacturer’s datasheet for detailed information on the material properties.

-

Layer stack-up: Design the layer stack-up of the PCB to achieve the desired characteristic impedance and minimize signal integrity issues. This involves selecting the appropriate layer thicknesses and dielectric constants.

-

Trace geometry: Optimize the trace geometry (width, spacing, and thickness) to achieve the desired characteristic impedance and minimize crosstalk. Use impedance calculators or simulation tools to determine the optimal trace dimensions.

-

Via design: Minimize the use of vias, especially in high-speed signal paths, to reduce discontinuities and reflections. When vias are necessary, use appropriate via geometries and spacing to minimize their impact on signal integrity.

-

Decoupling and bypassing: Implement proper decoupling and bypassing techniques to maintain power integrity. This includes placing decoupling capacitors close to the power pins of components and using appropriate values based on the relative permittivity of FR4.

-

Grounding and shielding: Employ good grounding and shielding practices to minimize electromagnetic interference (EMI) and ensure EMC. This includes proper ground plane design, use of ground vias, and shielding of sensitive signals when necessary.

-

Simulation and validation: Perform signal and power integrity simulations to validate the PCB design before fabrication. Use electromagnetic simulation tools to analyze the behavior of the PCB and identify potential issues.

Frequently Asked Questions (FAQ)

-

What is the typical relative permittivity of FR4?

The typical relative permittivity of FR4 ranges from 4.2 to 4.8 at room temperature and low frequencies (< 1 GHz). However, the exact value can vary depending on the specific formulation of the material and environmental conditions. -

How does the relative permittivity of FR4 affect signal propagation speed?

The signal propagation speed in FR4 is inversely proportional to the square root of its relative permittivity. A higher relative permittivity results in slower signal propagation speeds, which can lead to increased signal delays in high-speed circuits. -

What factors can influence the relative permittivity of FR4?

Several factors can influence the relative permittivity of FR4, including frequency, temperature, moisture content, and the type and amount of fillers used in the material formulation. -

How does the relative permittivity of FR4 impact electromagnetic compatibility (EMC)?

The relative permittivity of FR4 can affect EMC by influencing crosstalk between adjacent traces and the radiated emissions from the PCB. A higher relative permittivity increases the coupling capacitance, which can lead to increased crosstalk and potential EMC issues. -

What design considerations should be taken into account when using FR4 for PCBs?

When designing PCBs with FR4, important considerations include material selection, layer stack-up design, trace geometry optimization, via design, proper decoupling and bypassing techniques, good grounding and shielding practices, and performing signal and power integrity simulations to validate the design.

Conclusion

The relative permittivity of FR4 is a critical parameter that influences the performance and reliability of PCBs. Understanding the typical values, factors affecting the relative permittivity, and its impact on signal integrity, power integrity, and EMC is essential for designing high-quality PCBs.

By considering the material properties, optimizing the PCB layout, and following best design practices, engineers can mitigate the challenges associated with the relative permittivity of FR4 and ensure the proper functioning of electronic systems across a wide range of frequencies and environmental conditions.

As technology advances and the demand for high-speed and high-frequency electronics grows, the importance of understanding and managing the relative permittivity of PCB substrate materials like FR4 will only continue to increase. Staying up-to-date with the latest research, measurement techniques, and design methodologies will be crucial for engineers to stay ahead in this ever-evolving field.

No responses yet