Factors Affecting PCB Double Layer Price

The price of a double layer PCB depends on several key variables:

Board Size and Complexity

The size of the PCB and the complexity of the circuit design are two of the most significant factors that impact the price. Larger boards require more material and take longer to manufacture, which increases the cost. Similarly, boards with intricate designs, tight tolerances, or a high component density are more challenging to produce and therefore more expensive.

Material Choice

The choice of material for the PCB substrate and the copper layers also affects the price. The most common substrate materials are FR-4, which is a glass-reinforced epoxy laminate, and aluminum. FR-4 is less expensive than aluminum but has lower thermal conductivity. The thickness of the copper layers also impacts the cost, with thicker layers being more expensive.

Quantity

As with most manufacturing processes, ordering PCBs in larger quantities generally reduces the per-unit cost. This is because the fixed costs associated with setting up the production run are spread out over a larger number of units. However, it’s important to balance the potential cost savings with the risk of ordering too many boards and having excess inventory.

Lead Time

The lead time, or the time between placing an order and receiving the finished boards, can also affect the price. Faster turnaround times often come at a premium, while longer lead times may offer cost savings. It’s important to plan ahead and allow sufficient time for production and shipping to avoid paying rush fees.

Additional Features

Any additional features or requirements beyond the standard specifications will likely increase the cost of the PCBs. This can include things like:

- Solder mask color

- Silkscreen color and artwork

- Surface finish (e.g., HASL, ENIG, OSP)

- Impedance control

- Via filling or plugging

- Countersinking or beveling

- Edge plating or gold fingers

Double Layer PCB Price Ranges

To give you a general idea of what you can expect to pay for double layer PCBs, we’ve compiled some price ranges based on board size and quantity. Keep in mind that these are rough estimates and actual prices may vary depending on the specific requirements of your project.

| Board Size | Quantity | Price Range |

|---|---|---|

| 50mm x 50mm | 10 | $50 – $100 |

| 50mm x 50mm | 100 | $100 – $200 |

| 50mm x 50mm | 1000 | $300 – $600 |

| 100mm x 100mm | 10 | $100 – $200 |

| 100mm x 100mm | 100 | $200 – $400 |

| 100mm x 100mm | 1000 | $600 – $1200 |

| 200mm x 200mm | 10 | $200 – $400 |

| 200mm x 200mm | 100 | $400 – $800 |

| 200mm x 200mm | 1000 | $1200 – $2400 |

As you can see, the price per unit decreases significantly as the quantity increases. For example, ordering 1000 boards of size 50mm x 50mm might cost $0.30 to $0.60 per board, while ordering only 10 boards of the same size could cost $5 to $10 per board.

Cost Comparison: Single Layer vs Double Layer PCBs

One of the main reasons to choose a double layer PCB over a single layer board is the increased circuit density and routing options. With two layers, you have more space to route traces and place components, which can allow for a smaller overall board size. However, this increased functionality comes at a higher cost.

To illustrate the difference in price between single and double layer PCBs, let’s compare some typical prices for a medium-sized board of 100mm x 100mm:

| Board Type | Quantity | Price Range | Price Per Unit |

|---|---|---|---|

| Single Layer | 100 | $100 – $200 | $1.00 – $2.00 |

| Double Layer | 100 | $200 – $400 | $2.00 – $4.00 |

As you can see, the price per unit for a double layer board is roughly twice that of a single layer board of the same size and quantity. This is because the double layer board requires more material, more processing steps, and more time to manufacture.

However, it’s important to consider the total cost of the project, not just the cost of the PCBs themselves. In some cases, using a double layer board may allow you to use a smaller board size or fewer components, which could offset the higher cost of the PCBs. It’s always a good idea to consult with your PCB manufacturer or design team to determine the most cost-effective solution for your specific project.

Choosing a PCB Manufacturer

When it comes to choosing a PCB manufacturer, there are a few key factors to consider:

- Reputation and experience

- Quality and reliability

- Pricing and lead times

- Customer service and support

It’s important to do your research and choose a manufacturer that has a proven track record of producing high-quality PCBs at competitive prices. Look for reviews and testimonials from other customers, and don’t be afraid to ask for references or samples before placing a large order.

There are many PCB manufacturers to choose from, both domestically and overseas. Some popular options include:

- Seeed Studio

- PCBWay

- JLCPCB

- OSH Park

- Sunstone Circuits

- Advanced Circuits

Each manufacturer has its own strengths and weaknesses, so it’s important to evaluate your specific needs and priorities when making a decision.

Tips for Optimizing PCB Cost

While the price of double layer PCBs is generally higher than single layer boards, there are several ways to optimize the cost and get the best value for your money:

-

Choose the right board size: Avoid overspecifying the board size and only use as much space as necessary for your circuit design. Smaller boards are generally less expensive than larger ones.

-

Minimize the number of layers: While double layer boards offer more routing options than single layer boards, they are still less expensive than multi-layer boards. If your design allows, stick with a double layer board to keep costs down.

-

Use standard materials and processes: Non-standard materials and processes can add significant cost to your PCBs. Stick with standard FR-4 substrate and copper weights, and avoid specialized requirements like impedance control or via filling unless absolutely necessary.

-

Plan ahead for production: Rushing production can lead to additional fees and higher costs. Plan ahead and allow sufficient time for manufacturing and shipping to avoid paying rush charges.

-

Order in bulk: As we’ve seen, ordering PCBs in larger quantities can dramatically reduce the per-unit cost. If you anticipate needing a large number of boards, consider placing a bulk order to take advantage of volume discounts.

Frequently Asked Questions

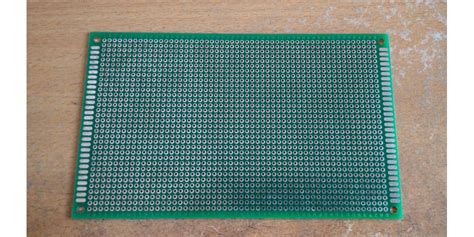

1. What is a double layer PCB?

A double layer PCB, also known as a two-layer PCB, is a printed circuit board that has two conductive copper layers, one on each side of the insulating substrate material. The two layers are connected by vias, which are small holes drilled through the board and plated with metal. Double layer PCBs offer more routing options and higher circuit density compared to single layer boards.

2. How much does a typical double layer PCB cost?

The cost of a double layer PCB can vary widely depending on factors such as board size, material, quantity, and additional features. As a rough estimate, a small (50mm x 50mm) double layer board might cost $5 to $10 per unit in low quantities (10-100), while a larger (200mm x 200mm) board could cost $20 to $40 per unit in similar quantities. Ordering larger quantities can significantly reduce the per-unit cost.

3. Why are double layer PCBs more expensive than single layer boards?

Double layer PCBs are more expensive than single layer boards because they require more material, more processing steps, and more time to manufacture. The additional copper layer and the need for vias to connect the layers add complexity and cost to the manufacturing process.

4. When should I choose a double layer PCB over a single layer board?

You should consider using a double layer PCB when your circuit design requires more routing space or higher component density than a single layer board can provide. Double layer boards also offer the advantage of being able to route signals on both sides of the board, which can help with signal integrity and EMI reduction.

5. How can I reduce the cost of my double layer PCBs?

There are several ways to optimize the cost of double layer PCBs:

- Choose the smallest board size that will accommodate your circuit design

- Minimize the number of layers and stick with standard materials and processes

- Plan ahead and allow sufficient lead time for production to avoid rush fees

- Order in bulk to take advantage of volume discounts

- Work with an experienced PCB manufacturer who can provide guidance and cost-saving suggestions

Conclusion

Double layer PCBs offer several advantages over single layer boards, including increased routing options, higher component density, and improved signal integrity. However, these benefits come at a higher cost due to the additional materials and processing steps required.

When considering the price of double layer PCBs, it’s important to take into account factors such as board size, material, quantity, lead time, and any additional features or requirements. By understanding these variables and working with an experienced PCB manufacturer, you can optimize the cost of your PCBs and get the best value for your project.

While the price of double layer PCBs may be higher than single layer boards, the increased functionality and reliability can often justify the added cost. By carefully evaluating your design requirements and balancing cost with performance, you can make an informed decision about whether double layer PCBs are the right choice for your project.

No responses yet