Understanding PCB mil thickness

PCB Thickness is expressed in mils, which is a unit of measurement equal to one-thousandth of an inch. For example, a PCB with a thickness of 62 mils is 0.062 inches thick. PCB thickness can range from as thin as 0.4 mils for flexible circuits to as thick as 200 mils or more for high-power applications.

The most common PCB thicknesses used in the electronics industry are:

| Mil Thickness | Inch Equivalent |

|---|---|

| 6 mils | 0.006″ |

| 12 mils | 0.012″ |

| 20 mils | 0.020″ |

| 31 mils | 0.031″ |

| 39 mils | 0.039″ |

| 59 mils | 0.059″ |

| 62 mils | 0.062″ |

| 93 mils | 0.093″ |

| 125 mils | 0.125″ |

The choice of PCB thickness depends on various factors, including the intended application, the number of layers, the required mechanical strength, and the electrical performance requirements.

Factors Affecting PCB Mil Thickness Selection

When selecting the appropriate mil thickness for a PCB, several factors must be taken into account to ensure optimal performance and reliability. These factors include:

1. Number of Layers

The number of layers in a PCB directly influences its thickness. As the number of layers increases, the overall thickness of the PCB also increases. For example, a typical 2-layer PCB may have a thickness of 31 mils, while a 6-layer PCB may have a thickness of 62 mils or more.

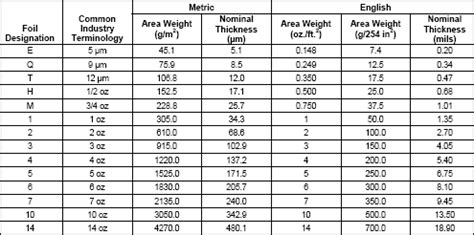

2. Copper Weight

The weight of the copper used in the PCB Layers also contributes to the overall thickness. Copper weight is measured in ounces per square foot (oz/ft²). Common copper weights include 0.5 oz/ft², 1 oz/ft², and 2 oz/ft². A higher copper weight results in a thicker PCB.

3. Application Requirements

The intended application of the PCB plays a crucial role in determining the appropriate mil thickness. For example, PCBs used in high-power applications or those exposed to harsh environmental conditions may require a thicker board for increased mechanical strength and thermal dissipation.

4. Manufacturing Capabilities

The manufacturing capabilities of the PCB fabricator also influence the choice of mil thickness. Some manufacturers may have limitations on the minimum or maximum thickness they can produce, as well as the available layer counts and copper weights.

Impact of PCB Mil Thickness on Performance

The mil thickness of a PCB can have a significant impact on its electrical, mechanical, and thermal performance. Let’s explore these aspects in more detail.

Electrical Performance

PCB thickness can affect the electrical performance of the board in several ways. Thinner PCBs may be more susceptible to signal integrity issues, such as crosstalk and electromagnetic interference (EMI). Thicker PCBs, on the other hand, can provide better insulation between layers, reducing the risk of signal integrity problems.

Additionally, the thickness of the PCB can impact its impedance control. Impedance control is crucial for high-speed digital circuits, as it ensures the integrity of the signals transmitted through the board. The thickness of the dielectric material between the signal traces and the reference plane (usually a ground or power plane) determines the characteristic impedance of the trace.

Mechanical Strength

The mechanical strength of a PCB is directly proportional to its thickness. Thicker PCBs are generally more rigid and less prone to bending, warping, or cracking under mechanical stress. This is particularly important for applications where the PCB is subject to vibration, shock, or other physical stresses.

However, it’s important to note that increasing the PCB thickness beyond a certain point may not necessarily improve its mechanical strength. In some cases, using a thicker PCB may even lead to issues such as increased weight and reduced flexibility.

Thermal Performance

PCB thickness can also impact the thermal performance of the board. Thicker PCBs have a greater thermal mass, which means they can absorb and dissipate heat more effectively than thinner PCBs. This is particularly important for high-power applications, where the PCB must be able to efficiently transfer heat away from components to prevent overheating and damage.

In addition to the overall thickness of the PCB, the thickness of the copper layers can also affect thermal performance. Thicker copper layers have a higher thermal conductivity, allowing for better heat dissipation.

Common PCB Mil Thickness Applications

Different applications often require specific PCB mil thicknesses to ensure optimal performance and reliability. Here are some common applications and their typical PCB thickness requirements:

Consumer Electronics

Consumer electronics, such as smartphones, tablets, and laptops, often use thin PCBs to minimize device thickness and weight. Common mil thicknesses for consumer electronics range from 20 mils to 62 mils, depending on the specific application and the number of layers required.

Industrial Electronics

Industrial electronics, such as control systems, sensors, and automation equipment, may require thicker PCBs to withstand harsh environmental conditions and provide better mechanical strength. Typical mil thicknesses for industrial electronics range from 62 mils to 125 mils.

Automotive Electronics

Automotive electronics, such as engine control units (ECUs), infotainment systems, and sensors, must be able to withstand extreme temperatures, vibrations, and other harsh conditions. As a result, automotive PCBs often have thicknesses ranging from 62 mils to 125 mils, depending on the specific application and requirements.

High-Power Applications

High-power applications, such as power supplies, motor drives, and energy storage systems, require PCBs with excellent thermal dissipation capabilities and mechanical strength. These applications often use thicker PCBs, ranging from 93 mils to 200 mils or more, to accommodate high-current traces and provide adequate heat dissipation.

FAQ

1. What is the most common PCB mil thickness?

The most common PCB mil thickness used in the electronics industry is 62 mils (0.062 inches). This thickness provides a good balance between mechanical strength, electrical performance, and cost for a wide range of applications.

2. Can I use a thinner PCB to reduce the overall size of my device?

Yes, using a thinner PCB can help reduce the overall size and weight of your device. However, it’s important to consider the trade-offs in terms of mechanical strength, signal integrity, and thermal performance. Make sure to select a thickness that meets your application’s specific requirements.

3. How does PCB thickness affect the cost of manufacturing?

In general, thicker PCBs are more expensive to manufacture than thinner ones. This is because thicker PCBs require more material, longer processing times, and specialized equipment. However, the cost difference between different thicknesses may not be significant for low-volume production runs.

4. Can I mix different mil thicknesses on the same PCB?

Yes, it is possible to have different mil thicknesses on the same PCB. This is known as a “stepped” or “sculpted” PCB. Stepped PCBs are often used in applications where certain areas of the board require additional thickness for mechanical strength or thermal dissipation, while other areas can be thinner to save space and weight.

5. How do I determine the appropriate mil thickness for my PCB?

To determine the appropriate mil thickness for your PCB, consider factors such as the number of layers, copper weight, application requirements, and manufacturing capabilities. Consult with your PCB manufacturer or design team to discuss your specific needs and find the optimal thickness for your application.

Conclusion

PCB mil thickness is a critical specification that can have a significant impact on the performance, reliability, and cost of a printed circuit board. When selecting the appropriate mil thickness for your PCB, it’s essential to consider factors such as the number of layers, copper weight, application requirements, and manufacturing capabilities.

By understanding the impact of PCB mil thickness on electrical, mechanical, and thermal performance, you can make informed decisions and ensure that your PCB meets the specific needs of your application. Whether you’re designing a thin PCB for a consumer device or a thick, high-power PCB for an industrial application, selecting the right mil thickness is key to achieving optimal results.

No responses yet