What is a High-Frequency PCB?

A high-frequency PCB is a specialized type of printed circuit board designed to operate at high frequencies, typically above 1 GHz. These PCBs are engineered to minimize signal loss, maintain signal integrity, and reduce electromagnetic interference (EMI) at high frequencies. High-frequency PCBs are commonly used in applications such as telecommunications, aerospace, defense, and high-speed computing.

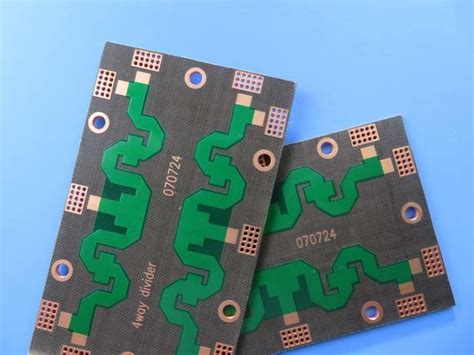

Characteristics of High-Frequency PCBs

High-frequency PCBs exhibit several distinct characteristics that set them apart from traditional PCBs:

-

Material selection: High-frequency PCBs require substrates with low dielectric constants and low loss tangents to minimize signal loss and maintain signal integrity. Common materials used for high-frequency PCBs include Rogers, Teflon, and PTFE.

-

Controlled impedance: To ensure proper signal transmission, high-frequency PCBs must have controlled impedance. This is achieved through precise control of the trace width, thickness, and spacing.

-

Shielding and grounding: High-frequency PCBs often incorporate shielding and grounding techniques to minimize EMI and crosstalk. This includes the use of ground planes, shielding vias, and proper grounding of components.

-

Minimized trace lengths: To reduce signal loss and maintain signal integrity, high-frequency PCBs aim to minimize trace lengths. This is achieved through careful component placement and routing optimization.

Applications of High-Frequency PCBs

High-frequency PCBs find applications in various industries where high-speed data transmission and processing are critical. Some of the common applications include:

-

Telecommunications: High-frequency PCBs are extensively used in telecommunications equipment such as 5G networks, base stations, and wireless communication devices.

-

Aerospace and defense: In the aerospace and defense sectors, high-frequency PCBs are employed in radar systems, satellite communication, and avionics.

-

High-speed computing: High-frequency PCBs are essential in high-speed computing applications, including servers, data centers, and supercomputers.

-

Automotive electronics: With the increasing adoption of advanced driver assistance systems (ADAS) and autonomous vehicles, high-frequency PCBs are becoming more prevalent in automotive electronics.

-

Medical devices: High-frequency PCBs are used in medical imaging systems, such as MRI and CT scanners, where high-speed data acquisition and processing are crucial.

Design Considerations for High-Frequency PCBs

Designing high-frequency PCBs requires careful consideration of several factors to ensure optimal performance and signal integrity. Some of the key design considerations include:

-

Material selection: Choosing the right substrate material is crucial for high-frequency PCBs. Factors such as dielectric constant, loss tangent, and thermal stability must be considered.

-

Controlled impedance: Designing traces with controlled impedance is essential to maintain signal integrity. This involves calculating the appropriate trace width, thickness, and spacing based on the desired impedance.

-

Shielding and grounding: Incorporating proper shielding and grounding techniques is necessary to minimize EMI and crosstalk. This includes the use of ground planes, shielding vias, and proper grounding of components.

-

Trace routing: Careful trace routing is crucial to minimize signal loss and maintain signal integrity. This involves minimizing trace lengths, avoiding sharp bends, and using appropriate via placement.

-

Component placement: Proper component placement is essential to minimize trace lengths and reduce signal loss. Components should be placed as close to each other as possible while considering thermal management and manufacturability.

-

Simulation and testing: Conducting simulations and testing is important to validate the design and ensure that the high-frequency PCB meets the desired performance requirements.

Highest Frequency PCBs

The highest frequency PCBs available in the market are designed to operate at frequencies beyond 100 GHz. These PCBs are used in cutting-edge applications such as millimeter-wave radar, high-speed data communication, and advanced scientific research.

Examples of High-Frequency PCBs

-

Rogers RO4000 Series: The Rogers RO4000 series is a popular choice for high-frequency PCBs. These laminates offer excellent high-frequency performance, with a dielectric constant of 3.48 to 3.66 and a loss tangent of 0.0037 to 0.0072 at 10 GHz.

-

Isola Astra MT77: Isola Astra MT77 is a low-loss, high-speed laminate designed for high-frequency applications. It has a dielectric constant of 3.0 and a loss tangent of 0.0017 at 10 GHz, making it suitable for applications up to 77 GHz.

-

PTFE (Teflon): PTFE, also known as Teflon, is a low-loss substrate material commonly used in high-frequency PCBs. It has a dielectric constant of 2.1 and a loss tangent of 0.0002 at 10 GHz, making it suitable for applications up to 100 GHz and beyond.

Highest Frequency PCB Applications

The highest frequency PCBs are used in advanced applications that require extremely high-speed data transmission and processing. Some of these applications include:

-

Millimeter-wave radar: Millimeter-wave radar systems operate at frequencies between 30 GHz and 300 GHz. These systems are used in automotive radar, security screening, and imaging applications.

-

High-speed data communication: High-frequency PCBs are essential in high-speed data communication applications, such as 5G networks, satellite communication, and high-speed Ethernet.

-

Scientific research: High-frequency PCBs are used in advanced scientific research, including particle accelerators, radio astronomy, and terahertz imaging.

FAQ

-

Q: What is the difference between a high-frequency PCB and a regular PCB?

A: High-frequency PCBs are designed to operate at higher frequencies (typically above 1 GHz) compared to regular PCBs. They use specialized materials, controlled impedance, and careful design techniques to minimize signal loss and maintain signal integrity at high frequencies. -

Q: What materials are commonly used for high-frequency PCBs?

A: Common materials used for high-frequency PCBs include Rogers, Teflon (PTFE), and low-loss laminates such as Isola Astra MT77. These materials have low dielectric constants and low loss tangents, which are essential for minimizing signal loss at high frequencies. -

Q: Why is controlled impedance important in high-frequency PCBs?

A: Controlled impedance is crucial in high-frequency PCBs to ensure proper signal transmission and maintain signal integrity. By precisely controlling the trace width, thickness, and spacing, designers can match the impedance of the traces to the desired value, minimizing reflections and signal distortions. -

Q: What are some of the challenges in designing high-frequency PCBs?

A: Designing high-frequency PCBs presents several challenges, including selecting the right materials, achieving controlled impedance, minimizing signal loss, and reducing electromagnetic interference (EMI). Designers must carefully consider factors such as trace routing, component placement, shielding, and grounding to ensure optimal performance. -

Q: What are some of the applications that require the highest frequency PCBs?

A: The highest frequency PCBs are used in advanced applications such as millimeter-wave radar systems, high-speed data communication (e.g., 5G networks), and scientific research involving particle accelerators, radio astronomy, and terahertz imaging. These applications demand extremely high-speed data transmission and processing, requiring PCBs that can operate at frequencies beyond 100 GHz.

| Frequency Range | Applications |

|---|---|

| 1 GHz – 10 GHz | Telecommunications, Wi-Fi, GPS, Bluetooth |

| 10 GHz – 30 GHz | Satellite communication, radar systems, 5G networks |

| 30 GHz – 100 GHz | Millimeter-wave radar, high-speed data communication, scientific research |

| 100 GHz and above | Advanced scientific research, terahertz imaging |

In conclusion, high-frequency PCBs are essential components in various applications that require high-speed data transmission and processing. These PCBs are designed to operate at frequencies above 1 GHz, with the highest frequency PCBs capable of operating beyond 100 GHz. Designing high-frequency PCBs requires careful consideration of materials, controlled impedance, shielding, grounding, and trace routing to ensure optimal performance and signal integrity. As technology continues to advance, the demand for high-frequency PCBs is expected to grow, driving innovation in telecommunications, aerospace, defense, high-speed computing, and scientific research.

No responses yet