Introduction to High Speed PCBs and Frequency

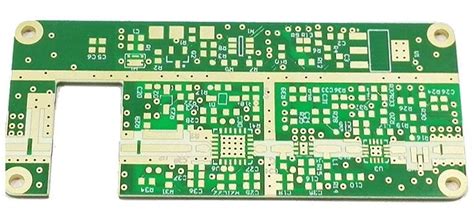

High speed printed circuit boards (PCBs) are designed to operate at high frequencies, enabling faster data transmission and processing in electronic devices. The frequency range of a high speed PCB is a crucial factor in determining its performance and suitability for specific applications. In this article, we will explore the frequency range of high speed PCBs, the factors that influence it, and its significance in various industries.

What is a High Speed PCB?

A high speed PCB is a specialized type of printed circuit board designed to handle high frequency signals and minimize signal integrity issues. These PCBs are engineered to maintain signal quality, reduce electromagnetic interference (EMI), and ensure reliable performance at elevated frequencies.

Importance of Frequency in High Speed PCBs

Frequency is a critical parameter in high speed PCB design as it directly impacts the board’s ability to transmit and process data efficiently. Higher frequencies allow for faster data transmission rates, enabling the development of advanced electronic devices and systems.

Factors Affecting PCB frequency Range

Several factors influence the frequency range of a high speed PCB. These factors must be carefully considered during the design and manufacturing process to ensure optimal performance.

Material Selection

The choice of PCB material plays a significant role in determining the frequency range. High frequency PCBs require materials with low dielectric constant (Dk) and low dissipation factor (Df) to minimize signal loss and distortion. Common materials used for high speed PCBs include:

- FR-4: A popular and cost-effective material suitable for frequencies up to 2 GHz.

- Rogers RO4000 series: High performance materials with low Dk and Df, ideal for frequencies up to 20 GHz.

- PTFE (Teflon): Low loss materials with excellent high frequency performance, suitable for frequencies beyond 20 GHz.

PCB Stack-up and Thickness

The PCB stack-up, which refers to the arrangement of copper layers and dielectric materials, affects the frequency range. A well-designed stack-up minimizes signal reflections, crosstalk, and EMI. The thickness of the PCB also impacts the frequency range, with thinner boards generally supporting higher frequencies.

Trace Width and Spacing

The width and spacing of the conductive traces on a PCB influence its frequency range. Narrower traces and tighter spacing enable higher frequencies but also increase the risk of signal integrity issues such as crosstalk and EMI. Careful design and simulation are necessary to optimize trace geometry for the desired frequency range.

Via Design and Placement

Vias, which are conductive holes that connect different layers of a PCB, can act as discontinuities and cause signal reflections at high frequencies. The design and placement of vias are critical for maintaining signal integrity. Techniques such as via shielding, back-drilling, and optimized via geometry can help mitigate the impact of vias on the frequency range.

Frequency Range of High Speed PCBs

The frequency range of high speed PCBs can vary depending on the specific application and design requirements. However, we can broadly categorize high speed PCBs into several frequency ranges:

| Frequency Range | Applications | PCB Materials |

|---|---|---|

| 1 GHz – 5 GHz | Wireless communication, GPS, Bluetooth | FR-4, Rogers RO4000 series |

| 5 GHz – 10 GHz | Radar, satellite communication, 5G networks | Rogers RO4000 series, PTFE |

| 10 GHz – 20 GHz | Millimeter-wave applications, high-speed data links | PTFE, low loss materials |

| 20 GHz and above | Research, advanced scientific instruments | PTFE, ultra-low loss materials |

It’s important to note that these frequency ranges are approximate and can overlap depending on the specific design and material choices.

Designing High Speed PCBs for Optimal Frequency Performance

To ensure that a high speed PCB operates effectively within its intended frequency range, several design considerations must be taken into account:

Signal Integrity Analysis

Signal integrity analysis is crucial for identifying and mitigating issues such as reflections, crosstalk, and EMI. Tools like time-domain reflectometry (TDR) and vector network analyzers (VNA) are used to characterize the PCB’s performance and optimize the design.

Impedance Matching

Proper impedance matching is essential for minimizing signal reflections and ensuring efficient power transfer. The characteristic impedance of the PCB traces must be matched to the source and load impedances to prevent reflections and signal distortion.

Ground Planes and Shielding

The use of ground planes and shielding techniques can help reduce EMI and maintain signal integrity at high frequencies. Solid ground planes provide a low-impedance return path for high-frequency currents, while shielding techniques like via fencing and guard traces can isolate sensitive signals from interference.

Simulation and Verification

Advanced simulation tools, such as electromagnetic field solvers and circuit simulators, are employed to predict the PCB’s performance at high frequencies. These simulations help identify potential issues early in the design process, allowing for iterative improvements and optimization.

Applications of High Speed PCBs

High speed PCBs find applications in various industries where high frequency operation and fast data processing are essential. Some notable applications include:

Telecommunications

High speed PCBs are extensively used in telecommunications equipment, such as routers, switches, and base stations. They enable high-bandwidth data transmission and support advanced communication protocols like 5G and beyond.

Aerospace and Defense

In aerospace and defense applications, high speed PCBs are used in radar systems, satellite communication equipment, and avionics. These PCBs must withstand harsh environmental conditions and meet stringent reliability requirements.

Automotive Electronics

The automotive industry increasingly relies on high speed PCBs for advanced driver assistance systems (ADAS), in-vehicle infotainment, and autonomous driving technologies. These PCBs must operate reliably in the challenging automotive environment.

Medical Devices

High speed PCBs are used in medical imaging equipment, such as MRI and CT scanners, where high-resolution data acquisition and processing are critical. They also find applications in patient monitoring systems and diagnostic devices.

Future Trends in High Speed PCB Design

As technology advances and the demand for higher data rates and faster processing continues to grow, the design of high speed PCBs will evolve to meet these challenges. Some future trends in high speed PCB design include:

Advanced Materials

The development of new, low-loss PCB materials with improved high frequency performance will enable the design of PCBs for even higher frequency ranges. Materials like liquid crystal polymers (LCP) and ultra-low loss ceramics are expected to gain traction in high speed applications.

3D Packaging and Integration

3D packaging techniques, such as through-silicon vias (TSVs) and chip stacking, will allow for higher-density interconnects and improved signal integrity at high frequencies. These techniques enable the integration of multiple dies and components in a compact package, reducing signal path lengths and enhancing overall performance.

Artificial Intelligence and Machine Learning

The application of artificial intelligence (AI) and machine learning (ML) techniques in PCB design will help optimize high speed layouts and predict signal integrity issues. AI-driven design tools can assist in the automatic routing of high-speed traces, placement of components, and simulation of PCB performance.

Frequently Asked Questions (FAQ)

-

Q: What is the typical frequency range for high speed PCBs used in 5G networks?

A: High speed PCBs for 5G networks typically operate in the frequency range of 5 GHz to 10 GHz, with some applications extending up to millimeter-wave frequencies (24 GHz and above). -

Q: Can FR-4 material be used for high speed PCBs?

A: FR-4 is a popular and cost-effective material for PCBs, but its performance is limited at high frequencies. It is generally suitable for frequencies up to 2 GHz. For higher frequencies, low-loss materials like Rogers RO4000 series or PTFE are recommended. -

Q: What is the impact of PCB thickness on the frequency range?

A: Thinner PCBs generally support higher frequencies due to reduced dielectric loss and improved signal propagation. However, the choice of PCB thickness must also consider other factors such as mechanical stability and manufacturability. -

Q: How can signal integrity be maintained at high frequencies?

A: Signal integrity at high frequencies can be maintained through careful design practices, including proper impedance matching, use of ground planes and shielding, optimized trace routing, and the use of advanced simulation tools for analysis and verification. -

Q: What are the challenges in designing high speed PCBs for automotive applications?

A: Automotive high speed PCBs must operate reliably in harsh environments, withstanding extreme temperatures, vibrations, and electromagnetic interference. They must also meet strict safety and reliability standards. Careful material selection, robust design, and extensive testing are crucial for automotive high speed PCBs.

Conclusion

The frequency range of a high speed PCB is a critical factor in determining its performance and suitability for various applications. By understanding the factors that influence the frequency range, such as material selection, stack-up, trace geometry, and via design, engineers can create PCBs that operate effectively at high frequencies.

As technology continues to advance, the demand for high speed PCBs will only grow. From telecommunications and aerospace to automotive and medical devices, high speed PCBs will play a vital role in enabling faster data transmission, processing, and communication.

By staying up-to-date with the latest design techniques, materials, and simulation tools, engineers can push the boundaries of high speed PCB design and develop innovative solutions for the most demanding applications.

No responses yet