Factors Affecting Mounting hole distance

The distance between mounting holes in a PCB depends on several factors, including:

PCB Size and Shape

The overall size and shape of the PCB is one of the primary factors that determines the spacing of mounting holes. Larger PCBs will typically have more widely spaced mounting holes to provide adequate support and prevent warping or flexing of the board. Smaller PCBs may have more closely spaced mounting holes due to space constraints.

The shape of the PCB also influences mounting hole placement. Rectangular PCBs will typically have mounting holes near the corners, while irregular-shaped PCBs may require mounting holes in specific locations to ensure proper mechanical support.

Industry Standards

There are several industry standards that specify recommended mounting hole sizes and spacing for various types of PCBs and enclosures. These standards are designed to ensure compatibility between PCBs and standard enclosure sizes, as well as to provide guidelines for proper mechanical support.

Some of the most common industry standards for PCB mounting holes include:

| Standard | Description |

|---|---|

| IPC-7351B | Generic Requirements for Surface Mount Design and Land Pattern Standards |

| IPC-2221 | Generic Standard on Printed Board Design |

| ANSI/VITA 57.1 | FPGA Mezzanine Card (FMC) Standard |

| IEEE 1101.1 | Mechanical Core Specifications for Microcomputers Using IEC 60603-2 Connectors |

These standards provide detailed specifications for mounting hole sizes, spacing, and layout for various types of PCBs and applications.

Component Placement

The placement of components on the PCB can also affect the spacing of mounting holes. Large components, such as connectors or heat sinks, may require additional mechanical support and may need to be located near mounting holes.

In some cases, the placement of components may limit the available space for mounting holes, requiring the designer to carefully plan the layout to ensure adequate mechanical support while avoiding interference with components.

Mechanical Constraints

The mechanical constraints of the enclosure or chassis where the PCB will be mounted also play a role in determining the spacing of mounting holes. The mounting holes on the PCB must align with the corresponding holes or standoffs in the enclosure to ensure proper fit and mechanical stability.

In some cases, the enclosure may have pre-defined mounting points that dictate the location of the mounting holes on the PCB. In other cases, the designer may have more flexibility to choose the location of the mounting holes based on the mechanical requirements of the PCB and components.

Recommended Mounting Hole Distances

While the exact spacing of mounting holes will depend on the specific requirements of each PCB design, there are some general guidelines and best practices that can be followed to ensure proper mechanical support and compatibility with standard enclosures.

Typical Mounting Hole Distances

For most standard PCB sizes and enclosures, the following mounting hole distances are commonly used:

| PCB Size | Typical Mounting Hole Distance |

|---|---|

| < 50mm | 2.54mm (0.1 inch) |

| 50-100mm | 3.81mm (0.15 inch) |

| 100-150mm | 5.08mm (0.2 inch) |

| 150-200mm | 6.35mm (0.25 inch) |

| > 200mm | 12.7mm (0.5 inch) or greater |

These distances provide a good starting point for most PCB designs, but the actual spacing may need to be adjusted based on the specific requirements of the design.

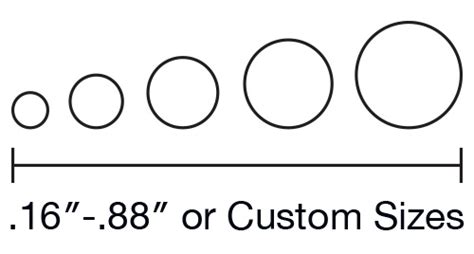

Mounting Hole Size

The size of the mounting holes is also an important consideration. The holes must be large enough to accommodate the mounting hardware, but not so large that they compromise the mechanical integrity of the PCB.

For most PCB designs, a mounting hole diameter of 3.2mm (0.125 inch) is sufficient for standard M3 screws. Larger mounting holes may be needed for larger screws or standoffs.

Edge Clearance

It is important to maintain adequate clearance between the mounting holes and the edges of the PCB to prevent damage during handling and assembly. A minimum edge clearance of 2.5mm (0.1 inch) is recommended for most PCB designs.

Mounting Hole Placement

When placing mounting holes on the PCB, it is important to consider the mechanical stress that will be placed on the board during use. Mounting holes should be placed in locations that will provide the most mechanical support for the PCB and components.

For rectangular PCBs, mounting holes are typically placed near the corners of the board to provide the most stable support. For irregular-shaped PCBs, mounting holes may need to be placed in specific locations to ensure proper support for the board and components.

Best Practices for Mounting Hole Placement

To ensure the best mechanical performance and reliability of your PCB design, follow these best practices for mounting hole placement:

-

Use industry-standard mounting hole sizes and spacing whenever possible to ensure compatibility with standard enclosures and hardware.

-

Place mounting holes near the corners of rectangular PCBs to provide the most stable mechanical support.

-

Maintain adequate clearance between mounting holes and the edges of the PCB to prevent damage during handling and assembly.

-

Consider the placement of components and mechanical stress points when determining the location of mounting holes.

-

Use additional mounting holes or support structures for large or heavy components that may require extra mechanical support.

-

Verify the alignment of mounting holes with the corresponding holes or standoffs in the enclosure or chassis to ensure proper fit and mechanical stability.

FAQ

What is the minimum distance between mounting holes on a PCB?

The minimum distance between mounting holes on a PCB depends on several factors, including the size of the PCB, the mechanical constraints of the enclosure, and the requirements of the specific design. As a general rule, a minimum distance of 2.54mm (0.1 inch) is recommended for most PCB designs.

Can I use different mounting hole sizes on the same PCB?

Yes, it is possible to use different mounting hole sizes on the same PCB, depending on the specific requirements of the design. However, it is generally recommended to use a consistent mounting hole size throughout the PCB to ensure compatibility with standard hardware and to simplify the assembly process.

How do I determine the best location for mounting holes on an irregular-shaped PCB?

The best location for mounting holes on an irregular-shaped PCB depends on the specific shape and mechanical requirements of the board. In general, mounting holes should be placed in locations that provide the most stable mechanical support for the PCB and components, while avoiding interference with other components or features of the board.

Can I use mounting holes for grounding or shielding purposes?

Yes, mounting holes can be used for grounding or shielding purposes in some PCB designs. By connecting the mounting holes to the ground plane or shielding layer of the PCB, you can provide additional grounding or shielding for sensitive components or signals. However, it is important to ensure that the mounting holes are properly sized and located to avoid compromising the mechanical integrity of the PCB.

What is the maximum distance between mounting holes on a PCB?

There is no specific maximum distance between mounting holes on a PCB, as the spacing will depend on the size and mechanical requirements of the specific design. However, as a general rule, mounting holes should be spaced as far apart as possible while still providing adequate mechanical support for the PCB and components. For larger PCBs, a distance of 12.7mm (0.5 inch) or greater between mounting holes is not uncommon.

Conclusion

Proper placement and spacing of mounting holes is a critical aspect of PCB design, ensuring compatibility with standard enclosures and providing the necessary mechanical support for the board and components. By considering factors such as PCB size and shape, industry standards, component placement, and mechanical constraints, designers can determine the optimal mounting hole distances for their specific PCB design.

By following best practices and guidelines for mounting hole placement, such as using industry-standard sizes and spacing, maintaining adequate edge clearance, and considering the mechanical stress points of the design, designers can create PCBs that are mechanically stable, reliable, and compatible with standard enclosures and hardware.

No responses yet