Introduction

When it comes to choosing materials for printed circuit boards (PCBs), two popular options are FR4 and polyimide. Both materials have unique properties that make them suitable for different applications. In this article, we will explore the differences between FR4 and polyimide, their advantages and disadvantages, and help you determine which material is best suited for your specific needs.

What is FR4?

FR4 (Flame Retardant 4) is a composite material made from woven fiberglass cloth and epoxy resin. It is the most commonly used material for PCBs due to its excellent mechanical and electrical properties, as well as its cost-effectiveness.

Composition of FR4

FR4 is composed of the following materials:

- Fiberglass cloth: This provides the substrate with mechanical strength and dimensional stability.

- Epoxy resin: The resin binds the fiberglass cloth together and provides insulation and flame retardancy.

- Copper foil: A thin layer of copper foil is laminated onto one or both sides of the substrate to create conductive traces and pads.

Properties of FR4

FR4 has several desirable properties that make it a popular choice for PCBs:

- High mechanical strength: FR4 has excellent tensile and flexural strength, making it resistant to vibration and shock.

- Good electrical insulation: The epoxy resin provides excellent insulation, preventing short circuits and signal interference.

- Flame retardancy: FR4 is designed to be flame-retardant, which is essential for safety in electronic applications.

- Wide operating temperature range: FR4 can operate in temperatures ranging from -55°C to 130°C, making it suitable for most consumer and industrial applications.

- Cost-effective: Compared to other PCB materials, FR4 is relatively inexpensive, making it a cost-effective choice for many applications.

Applications of FR4

FR4 is widely used in various industries and applications, including:

- Consumer electronics: Smartphones, laptops, televisions, and other household electronic devices.

- Industrial electronics: Control systems, automation equipment, and power supplies.

- Automotive electronics: Engine control units, infotainment systems, and sensors.

- Medical devices: Diagnostic equipment, monitoring systems, and implantable devices.

- Aerospace and defense: Avionics, communication systems, and radar equipment.

What is Polyimide?

Polyimide is a high-performance polymer material that offers superior thermal, mechanical, and electrical properties compared to FR4. It is often used in applications that demand higher reliability and performance.

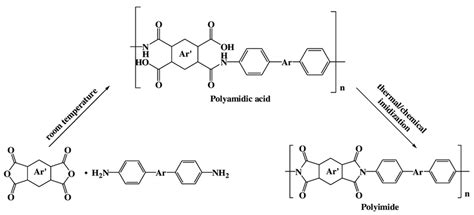

Composition of Polyimide

Polyimide is a synthetic polymer composed of repeating imide monomers. The most common type of polyimide used in PCBs is Kapton, which is a registered trademark of DuPont.

Properties of Polyimide

Polyimide has several unique properties that make it an attractive choice for high-performance applications:

- High thermal stability: Polyimide can withstand temperatures up to 400°C, making it suitable for applications that experience extreme heat.

- Excellent mechanical strength: Polyimide has high tensile strength and is resistant to tear and abrasion.

- Superior electrical insulation: Polyimide offers better insulation properties than FR4, making it ideal for high-voltage applications.

- Low Dielectric Constant: The low dielectric constant of polyimide enables faster signal transmission and reduced signal loss.

- Flexibility: Polyimide films are flexible, allowing for the creation of flexible PCBs that can conform to various shapes and sizes.

Applications of Polyimide

Polyimide is used in various high-performance applications, such as:

- Aerospace and defense: Satellites, missiles, and high-speed aircraft.

- Automotive: Under-the-hood electronics and high-temperature sensors.

- Medical devices: Implantable devices and surgical instruments.

- Industrial: High-temperature environments, such as oil and gas exploration, and chemical processing.

- Consumer electronics: Flexible displays and wearable devices.

FR4 vs Polyimide: Key Differences

Now that we have a basic understanding of FR4 and polyimide, let’s compare their key differences:

Thermal Stability

| Material | Maximum Operating Temperature |

|---|---|

| FR4 | 130°C |

| Polyimide | 400°C |

Polyimide offers significantly higher thermal stability compared to FR4, making it suitable for applications that experience extreme temperatures.

Mechanical Strength

| Material | Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|

| FR4 | 415 | 415 |

| Polyimide | 231 | 345 |

While FR4 has higher tensile strength, polyimide offers better flexural strength and is more resistant to tear and abrasion.

Electrical Properties

| Material | Dielectric Constant @ 1 MHz | Dielectric Strength (kV/mm) |

|---|---|---|

| FR4 | 4.7 | 20 |

| Polyimide | 3.5 | 200 |

Polyimide has a lower dielectric constant and higher dielectric strength compared to FR4, making it better suited for high-frequency and high-voltage applications.

Cost

FR4 is significantly less expensive than polyimide. The cost of polyimide can be 5 to 10 times higher than FR4, depending on the specific grade and manufacturer.

Choosing Between FR4 and Polyimide

When deciding between FR4 and polyimide for your PCB application, consider the following factors:

- Operating temperature: If your application experiences extreme temperatures, polyimide may be the better choice.

- Electrical requirements: For high-frequency or high-voltage applications, polyimide’s superior electrical properties may be necessary.

- Mechanical requirements: If your application demands high flexural strength or resistance to tear and abrasion, polyimide may be the better option.

- Cost: If cost is a primary concern, FR4 is the more economical choice.

Ultimately, the choice between FR4 and polyimide depends on the specific requirements of your application. It’s essential to carefully consider the trade-offs between performance and cost when making your decision.

FAQ

-

Q: Can FR4 be used for high-temperature applications?

A: FR4 is suitable for applications with operating temperatures up to 130°C. For higher temperatures, polyimide is a better choice. -

Q: Is polyimide more expensive than FR4?

A: Yes, polyimide is significantly more expensive than FR4, with costs ranging from 5 to 10 times higher. -

Q: Which material is better for high-frequency applications?

A: Polyimide has a lower dielectric constant compared to FR4, making it better suited for high-frequency applications. -

Q: Can polyimide be used to create flexible PCBs?

A: Yes, polyimide films are flexible and can be used to create flexible PCBs that conform to various shapes and sizes. -

Q: Is FR4 suitable for most consumer electronic applications?

A: Yes, FR4 is a cost-effective and widely used material for most consumer electronic applications, such as smartphones, laptops, and televisions.

Conclusion

FR4 and polyimide are two popular materials used in the production of printed circuit boards. While FR4 is the most common and cost-effective choice for many applications, polyimide offers superior thermal, mechanical, and electrical properties, making it better suited for high-performance applications. When choosing between FR4 and polyimide, it’s essential to consider the specific requirements of your application, including operating temperature, electrical and mechanical demands, and cost constraints. By understanding the key differences between these two materials, you can make an informed decision and select the best option for your PCB project.

No responses yet