Introduction to FR4 and PCB

In the world of electronics, printed circuit boards (PCBs) are essential components that provide a foundation for mounting and interconnecting electronic components. When it comes to PCB materials, FR4 is one of the most commonly used substrates. However, there is often confusion between the terms “FR4” and “PCB.” In this article, we will explore the differences between FR4 and PCB, their properties, applications, and answer some frequently asked questions.

What is FR4?

FR4 (Flame Retardant 4) is a type of glass-reinforced epoxy laminate material used in the production of PCBs. It is a composite material made by combining woven fiberglass cloth with an epoxy resin binder. The “FR” in FR4 stands for “Flame Retardant,” indicating its ability to resist the spread of flames in case of a fire.

Properties of FR4

FR4 possesses several desirable properties that make it an ideal choice for PCB manufacturing:

- High mechanical strength and durability

- Excellent electrical insulation properties

- Good thermal stability

- Resistance to moisture absorption

- Flame retardancy

These properties enable FR4 to withstand the rigors of PCB Assembly processes and provide reliable performance in various operating conditions.

Applications of FR4

FR4 is widely used in the electronics industry for a variety of applications, including:

- Consumer electronics (e.g., smartphones, laptops, televisions)

- Industrial equipment (e.g., control systems, automation devices)

- Automotive electronics (e.g., engine control units, infotainment systems)

- Medical devices (e.g., monitoring equipment, diagnostic tools)

- Telecommunications (e.g., routers, switches, base stations)

The versatility and reliability of FR4 make it a popular choice for PCB designers and manufacturers across different sectors.

What is PCB?

A printed circuit board (PCB) is a flat board made of insulating material, such as FR4, with conductive pathways etched or printed onto its surface. PCBs serve as the foundation for mounting and interconnecting electronic components, such as resistors, capacitors, integrated circuits (ICs), and connectors.

Types of PCBs

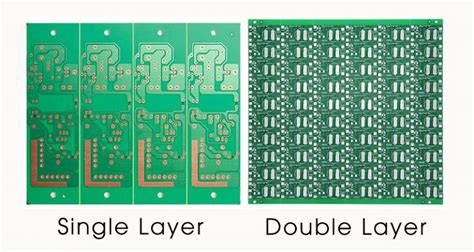

PCBs can be classified into different types based on their construction and the number of conductive layers:

- Single-sided PCB: Contains conductive traces on one side of the board.

- Double-sided PCB: Has conductive traces on both sides of the board, with through-hole connections.

- Multi-layer PCB: Consists of multiple layers of conductive traces separated by insulating layers, enabling more complex routing and higher component density.

- Flexible PCB: Made from flexible materials, allowing the board to bend and conform to various shapes.

- Rigid-Flex PCB: Combines rigid and flexible sections in a single board for unique packaging requirements.

PCB Manufacturing Process

The PCB manufacturing process typically involves the following steps:

- Design: Creating the PCB layout using specialized software.

- Printing: Transferring the PCB design onto the Copper-Clad Laminate using photoresist and exposure to light.

- Etching: Removing unwanted copper from the laminate using a chemical etching process.

- Drilling: Creating holes for through-hole components and vias.

- Plating: Applying a thin layer of metal (e.g., copper, gold) to the holes and surface to improve conductivity and protect against corrosion.

- Solder Mask: Applying a protective coating to the PCB surface, leaving exposed areas for component soldering.

- Silkscreen: Printing text, symbols, and component designators onto the PCB surface for easy identification.

- Surface Finish: Applying a final protective layer (e.g., HASL, ENIG) to the exposed copper areas to prevent oxidation and enhance solderability.

FR4 vs PCB: Key Differences

While FR4 and PCB are closely related, they are not the same thing. Here are the key differences between FR4 and PCB:

- Definition: FR4 is a specific material used in PCB manufacturing, while PCB refers to the complete printed circuit board.

- Composition: FR4 is a glass-reinforced epoxy laminate, whereas a PCB is made up of an insulating substrate (such as FR4) with conductive traces and components.

- Function: FR4 provides the structural support and insulation for the PCB, while the PCB serves as the platform for mounting and interconnecting electronic components.

- Variants: FR4 is one of many laminate materials used in PCB manufacturing, while PCBs can be classified into different types based on their construction and the number of layers.

| Aspect | FR4 | PCB |

|---|---|---|

| Definition | A glass-reinforced epoxy laminate material | A complete printed circuit board |

| Composition | Woven fiberglass cloth with an epoxy resin binder | An insulating substrate with conductive traces and components |

| Function | Provides structural support and insulation | Serves as a platform for mounting and interconnecting electronic components |

| Variants | One of many laminate materials used in PCB manufacturing | Different types based on construction and number of layers |

FAQ

-

Q: Can FR4 be used for high-frequency applications?

A: Yes, FR4 can be used for high-frequency applications up to a certain extent. However, for very high-frequency applications (e.g., microwave frequencies), specialized materials like Rogers laminates may be more suitable due to their better dielectric properties. -

Q: Are there any alternatives to FR4 for PCB manufacturing?

A: Yes, there are several alternative materials used in PCB manufacturing, depending on the specific requirements of the application. Some examples include polyimide (PI), PTFE (Teflon), and ceramic-based substrates. -

Q: What is the typical thickness of an FR4 PCB?

A: FR4 PCBs are available in various thicknesses, typically ranging from 0.4mm to 3.2mm. The most common thicknesses are 0.8mm, 1.6mm, and 2.4mm. -

Q: Can FR4 PCBs be used in high-temperature environments?

A: FR4 PCBs have a glass transition temperature (Tg) of around 130°C to 140°C, which limits their use in high-temperature environments. For applications that require higher operating temperatures, alternative materials like polyimide (PI) or ceramic-based substrates may be more suitable. -

Q: What is the difference between HASL and ENIG surface finishes for PCBs?

A: HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold) are two common surface finishes used in PCB manufacturing. HASL involves dipping the PCB in molten solder, while ENIG is a chemical process that deposits a layer of nickel followed by a thin layer of gold. ENIG offers better planarity and is suitable for fine-pitch components, while HASL is more cost-effective and provides good solderability.

Conclusion

In summary, FR4 is a glass-reinforced epoxy laminate material commonly used in the manufacturing of printed circuit boards (PCBs). It provides the necessary structural support, insulation, and flame retardancy for PCBs. On the other hand, a PCB is a complete board that incorporates an insulating substrate (such as FR4) with conductive traces and components.

Understanding the differences between FR4 and PCB is essential for electronics designers, manufacturers, and enthusiasts. By leveraging the properties of FR4 and the various types of PCBs available, it is possible to create reliable and high-performance electronic devices across a wide range of applications.

As technology continues to advance, the demand for more sophisticated and compact PCBs will only increase. Innovations in materials, manufacturing processes, and design techniques will play a crucial role in meeting these evolving requirements while ensuring the reliability and functionality of electronic devices.

No responses yet