Introduction to PCB Materials

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide a platform for mounting and interconnecting electronic components to create a functional circuit. The choice of PCB material is crucial as it determines the performance, reliability, and cost of the final product. Two commonly used PCB materials are aluminum and FR4. In this article, we will explore the differences between these two materials and their applications.

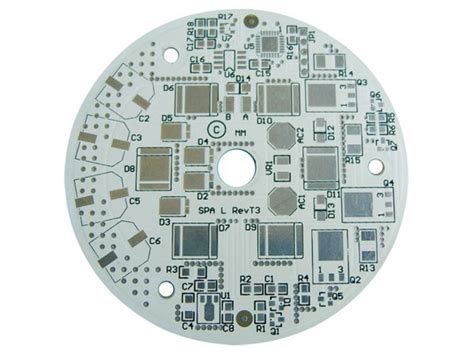

What is Aluminum PCB?

Aluminum PCBs are made by bonding a thin layer of copper foil to an aluminum substrate. The copper layer is then etched to create the desired circuit pattern. Aluminum PCBs offer several advantages over traditional FR4 PCBs:

- Excellent thermal conductivity

- Lightweight and durable

- Good electrical conductivity

- Cost-effective for high-volume production

Advantages of Aluminum PCBs

Thermal Management

One of the main advantages of aluminum PCBs is their excellent thermal conductivity. Aluminum has a thermal conductivity of 205 W/mK, which is significantly higher than FR4 (0.3 W/mK). This means that aluminum PCBs can efficiently dissipate heat generated by electronic components, preventing overheating and ensuring stable performance.

Lightweight and Durable

Aluminum PCBs are lighter than FR4 PCBs of the same size, making them ideal for applications where weight is a critical factor, such as in aerospace and automotive industries. Additionally, aluminum PCBs are more durable and resistant to vibration and shock, which enhances their reliability in harsh environments.

Electrical Conductivity

Aluminum is an excellent electrical conductor, with a conductivity of 3.5 x 10^7 S/m. This high conductivity allows for the design of PCBs with lower impedance and reduced signal loss, which is particularly important for high-frequency applications.

Cost-Effective for High-Volume Production

Aluminum PCBs can be more cost-effective than FR4 PCBs for high-volume production. The raw materials for aluminum PCBs are generally cheaper than those for FR4 PCBs, and the manufacturing process is simpler, resulting in lower production costs.

Disadvantages of Aluminum PCBs

Despite their advantages, aluminum PCBs also have some limitations:

- Limited design flexibility due to the single-sided nature of aluminum PCBs

- Higher tooling costs for low-volume production

- Potential for galvanic corrosion if not properly protected

What is FR4 PCB?

FR4 (Flame Retardant 4) is a glass-reinforced epoxy laminate material used in the majority of PCBs. It consists of a woven fiberglass fabric impregnated with an epoxy resin binder. FR4 PCBs offer several advantages:

- Excellent electrical insulation properties

- Good mechanical strength and dimensional stability

- Flame retardant and self-extinguishing

- Suitable for multi-layer PCB designs

Advantages of FR4 PCBs

Electrical Insulation

FR4 has excellent electrical insulation properties, with a dielectric constant of 4.5 at 1 MHz and a dielectric strength of 20 kV/mm. This makes FR4 PCBs suitable for a wide range of applications, from low-voltage digital circuits to high-voltage power electronics.

Mechanical Strength and Dimensional Stability

The glass reinforcement in FR4 provides good mechanical strength and dimensional stability. FR4 PCBs are resistant to bending, twisting, and warping, which ensures the integrity of the circuit and the reliability of the electronic device.

Flame Retardant and Self-Extinguishing

FR4 is a flame-retardant material that meets the UL94 V-0 flammability rating. This means that FR4 PCBs are self-extinguishing and will not support combustion, reducing the risk of fire in electronic devices.

Multi-Layer PCB Design

FR4 is suitable for manufacturing multi-layer PCBs, which allows for more complex circuit designs and higher component density. Multi-layer FR4 PCBs can accommodate a larger number of components and interconnections in a smaller space, making them ideal for compact electronic devices.

Disadvantages of FR4 PCBs

FR4 PCBs also have some limitations:

- Poor thermal conductivity compared to aluminum PCBs

- Higher material costs than aluminum PCBs

- Not suitable for high-frequency applications due to dielectric losses

Comparison of Aluminum and FR4 PCBs

| Property | Aluminum PCB | FR4 PCB |

|---|---|---|

| Thermal Conductivity | High (205 W/mK) | Low (0.3 W/mK) |

| Electrical Insulation | Poor | Excellent |

| Mechanical Strength | Good | Excellent |

| Weight | Lightweight | Heavier than aluminum |

| Design Flexibility | Limited (single-sided) | High (multi-layer) |

| Cost (High-Volume) | Lower | Higher |

| Cost (Low-Volume) | Higher (tooling costs) | Lower |

| Suitable Applications | – High-power electronics – LED lighting – Automotive electronics |

– Digital circuits – Telecommunications – Consumer electronics |

Applications of Aluminum and FR4 PCBs

Aluminum PCB Applications

Aluminum PCBs are commonly used in applications that require excellent thermal management, such as:

- High-power LED lighting systems

- Automotive electronics (e.g., engine control units, power converters)

- Power electronics (e.g., switchmode power supplies, inverters)

- Aerospace and defense electronics

FR4 PCB Applications

FR4 PCBs are widely used in a variety of electronic applications, including:

- Digital circuits (e.g., microcontrollers, memory modules)

- Telecommunications equipment (e.g., routers, switches)

- Consumer electronics (e.g., smartphones, laptops)

- Industrial control systems (e.g., PLCs, sensors)

FAQ

-

Q: Can aluminum PCBs be used for multi-layer designs?

A: No, aluminum PCBs are typically single-sided due to the manufacturing process and the nature of the aluminum substrate. -

Q: Are FR4 PCBs suitable for high-temperature applications?

A: Standard FR4 PCBs are rated for operating temperatures up to 130°C. For higher temperatures, specialized FR4 variants like high Tg FR4 or polyimide-based laminates can be used. -

Q: How do aluminum PCBs compare to other metal-core PCBs?

A: Aluminum PCBs are the most common type of metal-core PCBs. Other materials, such as copper and steel, can also be used, but they are less common due to higher costs and manufacturing challenges. -

Q: Can FR4 PCBs be used for high-frequency applications?

A: Standard FR4 PCBs are not ideal for high-frequency applications due to dielectric losses. For high-frequency applications, low-loss materials like Rogers laminates or PTFE-based substrates are preferred. -

Q: Are aluminum PCBs more environmentally friendly than FR4 PCBs?

A: Aluminum PCBs can be considered more environmentally friendly than FR4 PCBs due to the recyclability of aluminum and the absence of brominated flame retardants. However, the overall environmental impact depends on various factors, such as the manufacturing process, transportation, and disposal.

Conclusion

Aluminum and FR4 are two common PCB materials with distinct properties and applications. Aluminum PCBs excel in thermal management, making them suitable for high-power electronics and applications where heat dissipation is critical. FR4 PCBs, on the other hand, offer excellent electrical insulation, mechanical strength, and multi-layer design capabilities, making them the go-to choice for a wide range of electronic applications.

When choosing between aluminum and FR4 PCBs, designers must consider factors such as the intended application, thermal requirements, design complexity, and cost. Understanding the differences between these two materials enables informed decisions and helps optimize the performance, reliability, and cost-effectiveness of electronic devices.

As technology continues to advance, new PCB materials and manufacturing techniques are emerging, offering even better performance and functionality. However, aluminum and FR4 PCBs remain the backbone of the electronics industry, and their importance in enabling innovative electronic solutions cannot be overstated.

No responses yet