Introduction to Rogers Material and its Dielectric Properties

Rogers Corporation is a leading manufacturer of high-performance materials for use in a wide range of applications, including printed circuit boards (PCBs), antennas, and microwave components. One of the key properties that makes Rogers materials so valuable for these applications is their Dielectric constant.

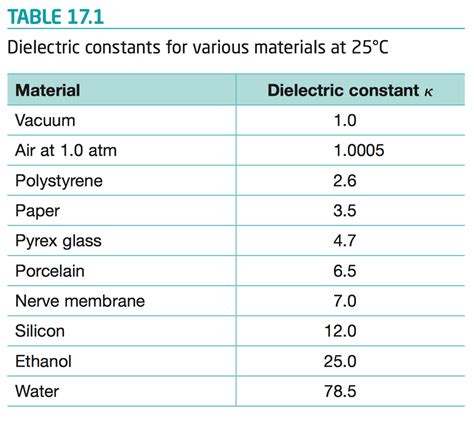

The dielectric constant, also known as the relative permittivity, is a measure of a material’s ability to store electrical energy in an electric field. It is a critical parameter in the design of high-frequency electronic circuits, as it affects the speed of signal propagation, impedance, and other important characteristics.

Rogers offers a variety of materials with different dielectric constants to suit different applications. In this article, we will explore the dielectric constant of some of the most popular Rogers materials and how it affects their performance in various applications.

Common Rogers Materials and their Dielectric Constants

Rogers offers a range of high-performance materials for use in PCBs, antennas, and other high-frequency applications. Some of the most popular Rogers materials include:

1. Rogers RO4000 Series

The Rogers RO4000 series is a family of high-performance laminate materials designed for use in PCBs and other high-frequency applications. These materials offer a low dielectric constant, low loss, and excellent thermal and mechanical properties.

The dielectric constant of RO4000 series materials ranges from 3.38 to 3.48 at 10 GHz, depending on the specific grade. The table below shows the dielectric constant of some common RO4000 series materials at 10 GHz:

| Material | Dielectric Constant at 10 GHz |

|---|---|

| RO4003C | 3.38 |

| RO4350B | 3.48 |

| RO4360G2 | 3.48 |

The low dielectric constant of RO4000 series materials makes them ideal for high-frequency applications where signal integrity and low loss are critical, such as in wireless communication systems and radar.

2. Rogers RT/duroid Series

The Rogers RT/duroid series is another family of high-performance laminate materials designed for use in PCBs and other high-frequency applications. These materials offer a higher dielectric constant than RO4000 series materials, making them suitable for applications where a higher dielectric constant is desired, such as in filters and couplers.

The dielectric constant of RT/duroid series materials ranges from 2.2 to 10.2 at 10 GHz, depending on the specific grade. The table below shows the dielectric constant of some common RT/duroid series materials at 10 GHz:

| Material | Dielectric Constant at 10 GHz |

|---|---|

| RT/duroid 5870 | 2.33 |

| RT/duroid 5880 | 2.20 |

| RT/duroid 6002 | 2.94 |

| RT/duroid 6006 | 6.15 |

| RT/duroid 6010LM | 10.2 |

The higher dielectric constant of RT/duroid series materials makes them ideal for applications where a higher capacitance or smaller circuit size is desired, such as in filters, couplers, and power dividers.

3. Rogers TMM Series

The Rogers TMM series is a family of thermoset ceramic loaded polymer composite materials designed for use in high-frequency applications. These materials offer a high dielectric constant, low loss, and excellent thermal and mechanical stability.

The dielectric constant of TMM series materials ranges from 3.27 to 9.8 at 10 GHz, depending on the specific grade. The table below shows the dielectric constant of some common TMM series materials at 10 GHz:

| Material | Dielectric Constant at 10 GHz |

|---|---|

| TMM3 | 3.27 |

| TMM4 | 4.5 |

| TMM6 | 6.0 |

| TMM10 | 9.2 |

| TMM10i | 9.8 |

The high dielectric constant of TMM series materials makes them ideal for applications where a high capacitance or small circuit size is desired, such as in filters, couplers, and power dividers.

Factors Affecting the Dielectric Constant of Rogers Materials

The dielectric constant of Rogers materials can be affected by several factors, including:

1. Frequency

The dielectric constant of Rogers materials varies with frequency. In general, the dielectric constant decreases with increasing frequency. This is because at higher frequencies, the molecules in the material have less time to polarize in response to the applied electric field.

2. Temperature

The dielectric constant of Rogers materials also varies with temperature. In general, the dielectric constant increases with increasing temperature. This is because at higher temperatures, the molecules in the material have more thermal energy and can polarize more easily in response to the applied electric field.

3. Moisture

Moisture can also affect the dielectric constant of Rogers materials. Water has a high dielectric constant (around 80), so even small amounts of moisture in the material can significantly increase its dielectric constant. This can lead to changes in the electrical properties of the material and affect the performance of the circuit.

4. Filler Material

Many Rogers materials are composite materials that contain a polymer matrix and a filler material, such as ceramic or glass. The type and amount of filler material can affect the dielectric constant of the material. In general, materials with a higher filler content tend to have a higher dielectric constant.

Applications of Rogers Materials Based on their Dielectric Constant

The dielectric constant of Rogers materials plays a critical role in their suitability for various applications. Some common applications of Rogers materials based on their dielectric constant include:

1. High-Frequency PCBs

Rogers materials with a low dielectric constant, such as RO4000 series materials, are ideal for use in high-frequency PCBs. The low dielectric constant allows for faster signal propagation and lower loss, which is critical for applications such as wireless communication systems and radar.

2. Antennas

Rogers materials with a low dielectric constant are also ideal for use in antennas. The low dielectric constant allows for a larger antenna size and better radiation efficiency, which is important for applications such as satellite communication and wireless networks.

3. Filters and Couplers

Rogers materials with a high dielectric constant, such as RT/duroid and TMM series materials, are ideal for use in filters and couplers. The high dielectric constant allows for a smaller circuit size and higher capacitance, which is important for applications such as power dividers and impedance matching networks.

4. Microwave Components

Rogers materials with a high dielectric constant are also ideal for use in microwave components, such as capacitors and resonators. The high dielectric constant allows for a smaller component size and higher energy storage, which is important for applications such as microwave filters and oscillators.

Conclusion

The dielectric constant is a critical parameter in the design of high-frequency electronic circuits, and Rogers materials offer a range of dielectric constants to suit different applications. From low dielectric constant materials like RO4000 series for high-frequency PCBs and antennas, to high dielectric constant materials like RT/duroid and TMM series for filters and microwave components, Rogers has a material to meet the needs of virtually any high-frequency application.

By understanding the factors that affect the dielectric constant of Rogers materials, such as frequency, temperature, moisture, and filler content, designers can select the appropriate material for their application and optimize its performance. With their excellent electrical, thermal, and mechanical properties, Rogers materials are a top choice for high-performance, high-frequency applications.

FAQ

1. What is the dielectric constant, and why is it important in high-frequency applications?

The dielectric constant, also known as relative permittivity, is a measure of a material’s ability to store electrical energy in an electric field. It is a critical parameter in high-frequency applications because it affects the speed of signal propagation, impedance, and other important characteristics of the circuit.

2. What are some common Rogers materials, and what are their typical dielectric constants?

Some common Rogers materials include RO4000 series, with dielectric constants ranging from 3.38 to 3.48 at 10 GHz; RT/duroid series, with dielectric constants ranging from 2.2 to 10.2 at 10 GHz; and TMM series, with dielectric constants ranging from 3.27 to 9.8 at 10 GHz.

3. How does the dielectric constant of Rogers materials vary with frequency?

The dielectric constant of Rogers materials generally decreases with increasing frequency. This is because at higher frequencies, the molecules in the material have less time to polarize in response to the applied electric field.

4. Can moisture affect the dielectric constant of Rogers materials?

Yes, moisture can significantly affect the dielectric constant of Rogers materials. Water has a high dielectric constant (around 80), so even small amounts of moisture in the material can increase its dielectric constant and affect the electrical properties of the circuit.

5. What are some applications of Rogers materials based on their dielectric constant?

Rogers materials with a low dielectric constant, such as RO4000 series, are ideal for high-frequency PCBs and antennas. Materials with a high dielectric constant, such as RT/duroid and TMM series, are ideal for filters, couplers, and microwave components, where a smaller circuit size and higher capacitance are desired.

No responses yet