Types of PCBs Based on Number of Layers

Single Layer PCBs

Single layer PCBs, also known as single-sided PCBs, have conductive traces on only one side of the board. These PCBs are the simplest and most cost-effective option, making them ideal for simple, low-density designs with few components. Single layer PCBs are commonly used in basic electronic devices, such as:

- Simple LED circuits

- Radio frequency (RF) circuits

- Low-power applications

- Educational projects

Advantages of single layer PCBs:

– Low cost

– Easy to design and manufacture

– Quick turnaround time

Disadvantages of single layer PCBs:

– Limited routing options

– Not suitable for complex circuits

– Limited heat dissipation

Double Layer PCBs

Double layer PCBs, also referred to as double-sided PCBs, have conductive traces on both sides of the board. These PCBs offer more flexibility in terms of component placement and routing compared to single layer PCBs. The two layers are connected using through-hole vias, allowing for more complex circuit designs. Double layer PCBs are commonly used in:

- Power supplies

- Amplifiers

- Automotive electronics

- Industrial control systems

Advantages of double layer PCBs:

– Increased routing options

– Higher component density

– Improved signal integrity

– Better heat dissipation

Disadvantages of double layer PCBs:

– Higher cost compared to single layer PCBs

– More complex design and manufacturing process

Multi-Layer PCBs

Multi-layer PCBs consist of three or more conductive layers, with insulating layers separating them. These PCBs offer the highest level of complexity and density, allowing for intricate circuit designs with numerous components. The layers are interconnected using through-hole vias and blind or buried vias. Multi-layer PCBs are commonly used in:

- High-speed digital devices

- Telecommunications equipment

- Medical devices

- Aerospace and defense applications

Advantages of multi-layer PCBs:

– High component density

– Excellent signal integrity

– Reduced electromagnetic interference (EMI)

– Improved heat dissipation

Disadvantages of multi-layer PCBs:

– High cost

– Complex design and manufacturing process

– Longer lead times

| PCB Type | Layers | Cost | Complexity | Applications |

|---|---|---|---|---|

| Single Layer | 1 | Low | Low | Simple circuits, RF, low-power |

| Double Layer | 2 | Medium | Medium | Power supplies, amplifiers, automotive |

| Multi-Layer | 3+ | High | High | High-speed digital, telecom, medical |

Types of PCBs Based on Rigidity

Rigid PCBs

Rigid PCBs are the most common type of PCBs, made from a solid substrate material, typically FR-4 (a glass-reinforced epoxy laminate). These PCBs maintain their shape and do not flex, making them suitable for a wide range of applications, including:

- Consumer electronics

- Industrial control systems

- Medical devices

- Automotive electronics

Advantages of rigid PCBs:

– Excellent mechanical stability

– High durability

– Compatible with various components and connectors

– Suitable for high-density designs

Disadvantages of rigid PCBs:

– Limited flexibility

– Not suitable for applications requiring conformity to curved surfaces

Flexible PCBs

Flexible PCBs, also known as flex PCBs, are made from flexible substrate materials, such as polyimide or polyester. These PCBs can bend and conform to various shapes, making them ideal for applications where flexibility and space constraints are crucial. Flexible PCBs are commonly used in:

- Wearable electronics

- Medical implants

- Automotive sensors

- Aerospace applications

Advantages of flexible PCBs:

– Flexibility and conformity to curved surfaces

– Lightweight and space-saving

– Improved shock and vibration resistance

– Reduced assembly time and costs

Disadvantages of flexible PCBs:

– Higher cost compared to rigid PCBs

– Limited component options

– Reduced heat dissipation

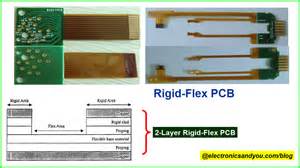

Rigid-Flex PCBs

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs, featuring rigid sections connected by flexible sections. This hybrid design allows for the integration of complex circuits in a compact and reliable package. Rigid-flex PCBs are commonly used in:

- Aerospace and defense applications

- Medical devices

- Automotive electronics

- High-density, space-constrained designs

Advantages of rigid-flex PCBs:

– Increased reliability and durability

– Reduced weight and space requirements

– Improved signal integrity

– Simplified assembly process

Disadvantages of rigid-flex PCBs:

– High cost

– Complex design and manufacturing process

– Longer lead times

| PCB Type | Substrate | Flexibility | Applications |

|---|---|---|---|

| Rigid | FR-4 | No | Consumer electronics, industrial, medical |

| Flexible | Polyimide | Yes | Wearables, medical implants, automotive |

| Rigid-Flex | FR-4 + Polyimide | Partial | Aerospace, defense, high-density designs |

Types of PCBs Based on Special Characteristics

High Frequency PCBs

High frequency PCBs are designed to handle high-speed signals, typically above 1 GHz. These PCBs require special materials and design techniques to minimize signal loss, distortion, and interference. High frequency PCBs are commonly used in:

- Wireless communication devices

- Radar systems

- Satellite communications

- High-speed digital circuits

Advantages of high frequency PCBs:

– Excellent signal integrity at high frequencies

– Reduced signal loss and distortion

– Improved electromagnetic compatibility (EMC)

Disadvantages of high frequency PCBs:

– Higher cost due to specialized materials and manufacturing processes

– Complex design requirements

– Increased sensitivity to environmental factors

High-Temperature PCBs

High-temperature PCBs are designed to withstand elevated temperatures, typically above 150°C. These PCBs use special substrate materials, such as polyimide or ceramic, and high-temperature solder masks and components. High-temperature PCBs are commonly used in:

- Automotive engine control units

- Aerospace applications

- Industrial power electronics

- Oil and gas exploration equipment

Advantages of high-temperature PCBs:

– Reliable operation in extreme temperature environments

– Increased durability and lifespan

– Compatibility with high-temperature components

Disadvantages of high-temperature PCBs:

– Higher cost due to specialized materials and manufacturing processes

– Limited component options

– Increased design complexity

Metal Core PCBs

Metal core PCBs (MCPCBs) feature a metal substrate, typically aluminum, instead of the traditional FR-4 substrate. The metal core provides excellent thermal conductivity, allowing for efficient heat dissipation from power-dense components. MCPCBs are commonly used in:

- LED lighting applications

- Power electronics

- High-power amplifiers

- Automotive electronics

Advantages of metal core PCBs:

– Excellent thermal management

– Increased reliability and lifespan of temperature-sensitive components

– Reduced size and weight compared to traditional heatsink solutions

Disadvantages of metal core PCBs:

– Higher cost compared to standard PCBs

– Limited design flexibility due to the metal substrate

– Potential for electrical shorts if not properly insulated

| PCB Type | Special Characteristic | Applications |

|---|---|---|

| High Frequency | High-speed signals | Wireless communication, radar, satellite |

| High-Temperature | Elevated temperatures | Automotive, aerospace, industrial power |

| Metal Core | Thermal management | LED lighting, power electronics, high-power amps |

Choosing the Best PCB Type for Your Application

When selecting the best PCB type for your application, consider the following factors:

- Circuit complexity: Determine the number of layers required based on the complexity of your circuit design.

- Flexibility requirements: Choose between rigid, flexible, or rigid-flex PCBs depending on the mechanical requirements of your application.

- Environmental conditions: Consider factors such as temperature, humidity, and vibration when selecting the appropriate PCB materials and construction.

- Signal integrity: For high-speed or high-frequency applications, choose PCB Types and materials that minimize signal loss and distortion.

- Thermal management: If your design includes power-dense components, consider using metal core PCBs or other thermal management techniques.

- Cost and lead time: Balance your performance requirements with cost and manufacturing lead times to select the most suitable PCB type for your project.

Frequently Asked Questions (FAQ)

- What is the difference between a single layer and a double layer PCB?

-

A single layer PCB has conductive traces on only one side of the board, while a double layer PCB has traces on both sides, offering more routing options and higher component density.

-

Can flexible PCBs be used in high-temperature applications?

-

Flexible PCBs made from high-temperature materials, such as polyimide, can withstand elevated temperatures. However, they may not be suitable for extremely high-temperature environments where rigid, ceramic-based PCBs are preferred.

-

Are multi-layer PCBs more expensive than single layer PCBs?

-

Yes, multi-layer PCBs are generally more expensive than single layer PCBs due to the increased complexity in design and manufacturing. The cost increases with the number of layers and the use of specialized materials.

-

What are the benefits of using metal core PCBs?

-

Metal core PCBs offer excellent thermal management, allowing for efficient heat dissipation from power-dense components. This improves the reliability and lifespan of temperature-sensitive components and reduces the need for additional heatsink solutions.

-

How do I choose the right PCB type for my project?

- When selecting the best PCB type for your project, consider factors such as circuit complexity, flexibility requirements, environmental conditions, signal integrity, thermal management, cost, and lead time. Consult with experienced PCB designers and manufacturers to determine the most suitable option for your specific application.

In conclusion, choosing the best PCB type for your application requires careful consideration of various factors, including circuit complexity, flexibility, environmental conditions, signal integrity, thermal management, cost, and lead time. By understanding the different types of PCBs and their characteristics, you can make an informed decision that balances your performance requirements with practical constraints. Whether you need a simple single layer PCB for a basic circuit or a complex multi-layer PCB for a high-speed digital device, selecting the right PCB type is crucial for the success of your electronic project.

No responses yet