Introduction to PCB and its Applications

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in almost every electronic device we use today, from smartphones and computers to medical equipment and aerospace systems. PCBs are essential components that provide mechanical support and electrical connectivity to electronic components. In this article, we will explore the various applications of PCBs and how they have revolutionized the electronics industry.

What is a PCB?

A PCB is a flat board made of insulating material, such as fiberglass or plastic, with conductive copper traces printed on its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits (ICs), to form a complete electronic circuit. PCBs can be single-sided, double-sided, or multi-layered, depending on the complexity of the circuit and the space constraints of the device.

Advantages of PCBs

PCBs offer several advantages over traditional point-to-point wiring methods. Some of the key benefits of PCBs include:

- Miniaturization: PCBs allow for the miniaturization of electronic devices by enabling the integration of multiple components on a single board.

- Reliability: PCBs provide a stable and reliable platform for electronic components, reducing the risk of short circuits and other failures.

- Cost-effectiveness: PCBs are cost-effective to manufacture in large quantities, making them ideal for mass production of electronic devices.

- Flexibility: PCBs can be designed to fit any shape or size, making them suitable for a wide range of applications.

Applications of PCBs

PCBs find applications in various industries, ranging from consumer electronics to aerospace and defense. Let’s explore some of the key application areas of PCBs.

Consumer Electronics

PCBs are extensively used in consumer electronics, such as:

- Smartphones: PCBs in smartphones integrate various components, such as processors, memory, sensors, and communication modules, enabling the devices to perform multiple functions in a compact form factor.

- Laptops and Desktops: PCBs in computers house the motherboard, which connects all the essential components, such as the CPU, RAM, storage, and peripherals.

- Televisions: PCBs in televisions control the display, audio, and input/output functions, enabling high-quality video and sound reproduction.

- Wearables: PCBs in wearable devices, such as smartwatches and fitness trackers, integrate sensors and communication modules to monitor health parameters and provide connectivity to smartphones.

Industrial Automation and Control Systems

PCBs play a crucial role in industrial automation and control systems, such as:

- Programmable Logic Controllers (PLCs): PCBs in PLCs enable the control and automation of industrial processes, such as assembly lines, packaging, and material handling.

- Human-Machine Interfaces (HMIs): PCBs in HMIs provide a user-friendly interface for operators to monitor and control industrial processes.

- Sensors and Actuators: PCBs in sensors and actuators enable the measurement and control of various parameters, such as temperature, pressure, flow, and position.

Medical Devices

PCBs are essential components in medical devices, such as:

- Diagnostic Equipment: PCBs in diagnostic equipment, such as X-ray machines, CT scanners, and MRI systems, enable high-resolution imaging and accurate diagnosis.

- Monitoring Systems: PCBs in patient monitoring systems, such as ECG, EEG, and pulse oximeters, enable real-time monitoring of vital signs and alert healthcare professionals in case of any abnormalities.

- Implantable Devices: PCBs in implantable devices, such as pacemakers and defibrillators, provide precise control and monitoring of the device’s functions, ensuring patient safety and well-being.

Aerospace and Defense

PCBs are critical components in aerospace and defense applications, such as:

- Avionics: PCBs in avionics systems, such as flight control, navigation, and communication systems, ensure the safe and efficient operation of aircraft and spacecraft.

- Radar and Surveillance: PCBs in radar and surveillance systems enable the detection, tracking, and identification of targets, enhancing situational awareness and decision-making capabilities.

- Missile Systems: PCBs in missile systems provide guidance, control, and communication functions, enabling precise targeting and engagement of threats.

Automotive

PCBs are increasingly used in automotive applications, such as:

- Engine Control Units (ECUs): PCBs in ECUs control various functions of the vehicle, such as fuel injection, ignition timing, and emission control, optimizing engine performance and fuel efficiency.

- Infotainment Systems: PCBs in infotainment systems provide audio, video, and navigation functions, enhancing the driving experience and passenger comfort.

- Advanced Driver Assistance Systems (ADAS): PCBs in ADAS, such as collision avoidance, lane departure warning, and adaptive cruise control, improve vehicle safety and reduce the risk of accidents.

Telecommunications

PCBs are the backbone of telecommunications networks, enabling the transmission and reception of voice, data, and video signals. Some of the key applications of PCBs in telecommunications include:

- Routers and Switches: PCBs in routers and switches enable the routing and switching of data packets, ensuring the efficient and reliable flow of information across networks.

- Base Stations: PCBs in base stations enable the transmission and reception of wireless signals, providing connectivity to mobile devices and enabling seamless communication.

- Fiber Optic Networks: PCBs in fiber optic networks enable the conversion of electrical signals to optical signals and vice versa, enabling high-speed data transmission over long distances.

PCB Design and Manufacturing

The design and manufacturing of PCBs involve several steps, including:

- Schematic Design: The first step in PCB design is to create a schematic diagram of the electronic circuit, specifying the components and their interconnections.

- Layout Design: The next step is to create a physical layout of the PCB, specifying the placement of components and the routing of traces.

- Fabrication: The PCB is then fabricated using a series of chemical and mechanical processes, including etching, drilling, and plating.

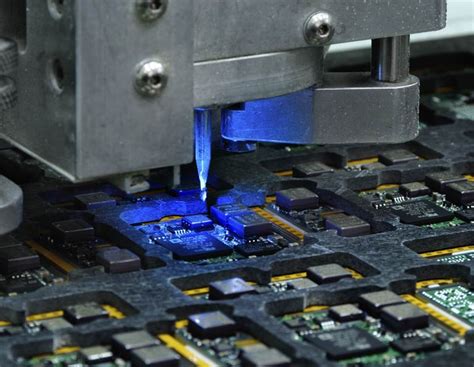

- Assembly: The electronic components are then soldered onto the PCB using automated assembly machines or manual soldering techniques.

- Testing: The assembled PCB is then tested for functionality and reliability using various methods, such as in-circuit testing, functional testing, and environmental testing.

| Step | Description |

|---|---|

| Schematic Design | Create a schematic diagram of the electronic circuit |

| Layout Design | Create a physical layout of the PCB |

| Fabrication | Fabricate the PCB using chemical and mechanical processes |

| Assembly | Solder the electronic components onto the PCB |

| Testing | Test the assembled PCB for functionality and reliability |

Future Trends in PCB Technology

PCB technology is constantly evolving to meet the increasing demands of the electronics industry. Some of the key trends in PCB technology include:

- Miniaturization: The trend towards miniaturization of electronic devices is driving the development of smaller and denser PCBs, with features such as embedded components and 3D packaging.

- High-Speed Design: The increasing demand for high-speed data transmission is driving the development of PCBs with faster signal propagation and lower signal loss, using materials such as low-loss dielectrics and high-frequency laminates.

- Flexible and Stretchable PCBs: The development of flexible and stretchable PCBs is enabling the integration of electronics into wearable devices, medical implants, and other applications that require conformable and durable electronics.

- Eco-Friendly Materials: The increasing focus on environmental sustainability is driving the development of PCBs using eco-friendly materials, such as halogen-free laminates and lead-free solders.

Conclusion

PCBs are essential components in modern electronics, providing a reliable and cost-effective platform for integrating electronic components. PCBs find applications in various industries, from consumer electronics to aerospace and defense, enabling the development of innovative and high-performance electronic devices. As PCB technology continues to evolve, we can expect to see even more advanced and sophisticated applications in the future.

Frequently Asked Questions (FAQ)

- What is the difference between a single-sided and double-sided PCB?

-

A single-sided PCB has conductive traces on only one side of the board, while a double-sided PCB has conductive traces on both sides of the board. Double-sided PCBs offer higher component density and better signal integrity than single-sided PCBs.

-

What is the purpose of solder mask on a PCB?

-

Solder mask is a protective coating applied to the surface of a PCB, covering the areas that do not require soldering. It prevents short circuits and corrosion, improves the aesthetics of the board, and helps in the soldering process by preventing solder bridging.

-

What is the difference between through-hole and surface-mount technology (SMT)?

-

Through-hole technology involves inserting component leads through holes drilled in the PCB and soldering them on the opposite side. SMT involves placing components directly on the surface of the PCB and soldering them in place. SMT offers higher component density and faster assembly than through-hole technology.

-

What is the purpose of a via in a PCB?

-

A via is a conductive hole drilled through the layers of a PCB, allowing signals to pass from one layer to another. Vias are used to interconnect traces on different layers, enabling more complex routing and higher component density.

-

What is the difference between a rigid and a flexible PCB?

- A rigid PCB is made of a solid substrate material, such as fiberglass or epoxy, and is designed to maintain its shape and rigidity. A flexible PCB is made of a flexible substrate material, such as polyimide or polyester, and can bend and flex without damaging the conductive traces. Flexible PCBs are used in applications that require conformable or movable electronics.

No responses yet