Introduction to Solder mask

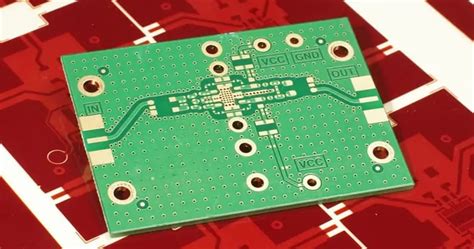

Solder mask, also known as solder resist or solder stop mask, is a thin layer of polymer applied to the copper traces of a printed circuit board (PCB) to protect them from oxidation and prevent solder bridges from forming between closely spaced solder pads. It is a crucial component in the manufacturing process of PCBs, as it ensures the reliability and functionality of the final product.

The Role of Solder Mask in PCB Manufacturing

In the PCB manufacturing process, solder mask plays several important roles:

-

Protection: Solder mask protects the copper traces from oxidation, corrosion, and physical damage during handling and assembly.

-

Insulation: It acts as an insulator between the copper traces, preventing short circuits and ensuring proper electrical connections.

-

Solder control: Solder mask defines the areas where solder should be applied during the soldering process, preventing solder bridges and ensuring precise solder joints.

-

Aesthetics: Solder mask is available in various colors, allowing for improved visual inspection and enhancing the overall appearance of the PCB.

Types of Solder Mask

There are two main types of solder mask used in PCB manufacturing:

Liquid Photoimageable Solder Mask (LPISM)

LPISM is the most common type of solder mask used in the industry. It is applied as a liquid coating and then exposed to UV light through a photomask, which hardens the exposed areas. The unexposed areas are then removed during the development process, leaving the desired solder mask pattern on the PCB.

Advantages of LPISM:

- High resolution and accuracy

- Excellent adhesion to the PCB surface

- Suitable for fine-pitch components and high-density designs

- Available in various colors

Dry Film Solder Mask (DFSM)

DFSM is a solid film that is laminated onto the PCB surface using heat and pressure. It is then exposed to UV light through a photomask, and the unexposed areas are removed during the development process.

Advantages of DFSM:

- Faster application process compared to LPISM

- Consistent thickness across the PCB

- Suitable for larger PCBs and lower-density designs

- Lower cost compared to LPISM

Solder Mask Application Process

The solder mask application process involves several steps:

-

Surface preparation: The PCB surface is cleaned and treated to ensure proper adhesion of the solder mask.

-

Solder mask application: The solder mask is applied to the PCB surface using either the LPISM or DFSM method.

-

Exposure: The solder mask is exposed to UV light through a photomask, which hardens the exposed areas.

-

Development: The unexposed areas of the solder mask are removed using a developer solution, leaving the desired solder mask pattern on the PCB.

-

Curing: The solder mask is fully cured using heat to ensure its durability and resistance to chemicals and environmental factors.

Solder Mask Properties and Specifications

When selecting a solder mask for a PCB, several properties and specifications should be considered:

Dielectric Strength

Dielectric strength is the maximum electric field that the solder mask can withstand before breaking down and allowing current to flow. A higher dielectric strength ensures better insulation between the copper traces.

| Solder Mask Type | Typical Dielectric Strength |

|---|---|

| LPISM | 50-100 kV/mm |

| DFSM | 80-150 kV/mm |

Flammability Rating

The flammability rating indicates the solder mask’s resistance to ignition and flame spread. The most common flammability rating for solder mask is UL94V-0, which means the material self-extinguishes within 10 seconds after being exposed to a flame.

Chemical Resistance

Solder mask should be resistant to various chemicals used in the PCB manufacturing process and during the product’s lifetime. These chemicals include:

- Flux

- Cleaning solvents

- Conformal coatings

- Potting compounds

Thermal Shock Resistance

Thermal shock resistance is the ability of the solder mask to withstand rapid changes in temperature without cracking or delaminating. This is particularly important for PCBs used in harsh environmental conditions or applications with frequent temperature fluctuations.

Surface Finish Compatibility

The solder mask should be compatible with the surface finish applied to the exposed copper areas of the PCB. Common surface finishes include:

- Hot Air Solder Leveling (HASL)

- Electroless Nickel Immersion Gold (ENIG)

- Immersion Silver

- Immersion Tin

- Organic Solderability Preservative (OSP)

Solder Mask Design Considerations

When designing a PCB with solder mask, several factors should be taken into account:

Solder Mask Clearance

Solder mask clearance is the distance between the edge of a copper pad and the solder mask opening. Adequate clearance is necessary to ensure proper solder joint formation and prevent solder mask from encroaching onto the pad.

| Pad Size | Recommended Solder Mask Clearance |

|---|---|

| ≤ 0.5 mm | 0.05 – 0.075 mm |

| > 0.5 mm | 0.075 – 0.1 mm |

Solder Mask Sliver

A solder mask sliver is a thin strip of solder mask between two closely spaced copper features. Slivers can be difficult to manufacture consistently and may lead to solder mask adhesion issues. It is recommended to maintain a minimum solder mask sliver width of 0.1 mm to 0.15 mm.

Solder Mask Bridge

A solder mask bridge is a narrow strip of solder mask connecting two adjacent solder mask openings. Bridges can help prevent solder bridges from forming between closely spaced pads but may also hinder the solder flow during the assembly process. The minimum recommended solder mask bridge width is 0.1 mm.

Solder Mask Dams

Solder mask dams are used to prevent solder from flowing onto adjacent pads or traces during the soldering process. They are particularly useful for fine-pitch components and high-density designs. The recommended solder mask dam width is 0.1 mm to 0.15 mm.

Solder Mask Color Options

Solder mask is available in a variety of colors, each serving different purposes:

- Green: The most common color, green solder mask provides good contrast for visual inspection and is suitable for most applications.

- Red: Red solder mask is often used for high-voltage or power electronics to indicate areas with higher voltage or current.

- Blue: Blue solder mask is sometimes used for aesthetic purposes or to differentiate between different board versions.

- Black: Black solder mask offers high contrast for white silkscreen markings and is often used for consumer electronics.

- White: White solder mask is used for LED lighting applications to enhance light reflection and improve efficiency.

- Yellow: Yellow solder mask is sometimes used for high-frequency or RF applications due to its lower dielectric constant compared to other colors.

Solder Mask and Assembly Processes

Solder mask plays a crucial role in various PCB Assembly processes:

Surface Mount Technology (SMT)

In SMT assembly, solder mask helps to define the solder pad areas and prevents solder bridges from forming between closely spaced components. It also protects the copper traces from damage during the Solder Paste printing and component placement processes.

Through-Hole Technology (THT)

For THT assembly, solder mask protects the copper traces and prevents solder from flowing onto adjacent pads during the wave soldering process. It also helps to contain the solder within the through-hole, ensuring a reliable solder joint.

Mixed Technology

Mixed technology PCBs combine both SMT and THT components. Solder mask is essential for ensuring proper solder joint formation and preventing solder bridges between the two types of components.

Solder Mask Inspection and Quality Control

To ensure the quality and reliability of the solder mask, several inspection and quality control methods are employed:

Visual Inspection

Visual inspection is the first line of defense in detecting solder mask defects. Inspectors look for issues such as:

- Solder mask adhesion problems

- Incomplete solder mask coverage

- Solder mask bridges or slivers

- Contamination or foreign objects

Automated Optical Inspection (AOI)

AOI systems use high-resolution cameras and advanced algorithms to detect solder mask defects automatically. These systems can identify issues such as:

- Solder mask misalignment

- Solder mask aperture size variations

- Solder mask thickness inconsistencies

Electrical Testing

Electrical testing is performed to ensure the solder mask’s insulation properties and detect any potential short circuits or leakage currents. Common tests include:

- Insulation resistance testing

- High-potential (hipot) testing

- Continuity testing

Troubleshooting Solder Mask Issues

Several common issues can arise during the solder mask application process or during PCB assembly:

Solder Mask Adhesion Problems

Solder mask adhesion issues can lead to delamination, exposing the copper traces to oxidation and potential damage. Causes of poor adhesion include:

- Contamination on the PCB surface

- Incorrect surface preparation

- Incompatible solder mask material

- Improper curing process

To resolve adhesion issues, ensure proper surface cleaning and treatment, select a compatible solder mask material, and optimize the curing process parameters.

Solder Mask Misalignment

Misaligned solder mask can lead to exposed copper traces or solder mask encroaching onto solder pads. This can cause soldering issues and affect the PCB’s functionality. Causes of solder mask misalignment include:

- Incorrect artwork or photomask

- Misalignment during the exposure process

- Stretching or shrinkage of the solder mask material

To prevent misalignment, ensure accurate artwork and photomask production, properly align the solder mask during exposure, and select a stable solder mask material.

Solder Mask Thickness Variations

Inconsistent solder mask thickness can lead to insulation and protection issues, as well as affect the PCB’s impedance and signal integrity. Causes of thickness variations include:

- Uneven solder mask application

- Incorrect exposure or development parameters

- Variations in the PCB surface topography

To maintain consistent solder mask thickness, optimize the application process, fine-tune the exposure and development parameters, and ensure a uniform PCB surface.

Frequently Asked Questions (FAQ)

-

What is the difference between solder mask and conformal coating?

Solder mask is applied to the PCB before the assembly process and is used to protect the copper traces and define the solderable areas. Conformal coating is applied after the assembly process and provides additional protection against moisture, dust, and other environmental factors. -

Can solder mask be removed?

Yes, solder mask can be removed using specialized chemicals or mechanical abrasion. However, removing solder mask can potentially damage the underlying copper traces and should only be done when necessary, such as for rework or repair purposes. -

What is the typical thickness of solder mask?

The typical thickness of solder mask ranges from 0.01 mm to 0.03 mm (10 to 30 microns). The exact thickness depends on the solder mask material and the application process used. -

How does solder mask affect PCB impedance?

Solder mask has a higher dielectric constant compared to air, which can affect the PCB’s impedance. When designing high-frequency or impedance-controlled PCBs, it is essential to consider the solder mask’s dielectric properties and thickness to ensure proper signal integrity. -

Can solder mask be applied to flexible PCBs?

Yes, solder mask can be applied to flexible PCBs using specialized materials and processes. Flexible solder mask materials are designed to withstand the bending and flexing of the PCB without cracking or delaminating.

Conclusion

Solder mask is an essential component in the PCB manufacturing process, providing protection, insulation, and solder control for the copper traces. Selecting the appropriate solder mask material, considering design factors, and implementing proper inspection and quality control methods are crucial for ensuring the reliability and functionality of the final PCB assembly.

By understanding the properties, applications, and troubleshooting techniques associated with solder mask, PCB Designers and manufacturers can optimize their processes and create high-quality, reliable electronic products.

No responses yet