Composition and Structure of RO4350B

RO4350B is a composite material consisting of a reinforced hydrocarbon and ceramic laminate with low dielectric loss tangent and low moisture absorption. The material’s structure comprises a ceramic-filled PTFE (polytetrafluoroethylene) composite, which is a proprietary blend of ceramic fillers and PTFE resin. This composition provides RO4350B with its excellent electrical properties and stability over a wide range of frequencies and temperatures.

The laminate is available in various thicknesses, typically ranging from 0.005″ to 0.060″ (0.13mm to 1.52mm), and can be clad with copper foil on one or both sides. The copper foil thickness options include 0.5 oz, 1 oz, and 2 oz (17 µm, 35 µm, and 70 µm), allowing for flexibility in PCB design and fabrication.

Electrical Properties of RO4350B

One of the key factors that make RO4350B stand out among other PCB Materials is its excellent electrical properties. The material has a dielectric constant (Dk) of 3.48 at 10 GHz, which remains stable over a wide frequency range. This stability is crucial for maintaining consistent performance in high-frequency applications, such as wireless communications, radar systems, and satellite technology.

Another important electrical property of RO4350B is its low dielectric loss tangent (Df) of 0.0037 at 10 GHz. A low loss tangent indicates that the material has minimal energy dissipation, resulting in lower signal attenuation and improved signal integrity. This property is particularly beneficial for applications that require high signal-to-noise ratios and minimal signal distortion.

The table below summarizes the key electrical properties of RO4350B:

| Property | Value |

|---|---|

| Dielectric Constant (Dk) | 3.48 at 10 GHz |

| Dielectric Loss Tangent (Df) | 0.0037 at 10 GHz |

| Volume Resistivity | 1.7 x 10^10 MΩ·cm |

| Surface Resistivity | 4.2 x 10^9 MΩ |

| Dielectric Breakdown | >60 kV/mm |

Thermal and Mechanical Properties

In addition to its excellent electrical properties, RO4350B also exhibits favorable thermal and mechanical properties. The material has a low coefficient of thermal expansion (CTE) of 15 ppm/°C in the X-Y plane and 30 ppm/°C in the Z-axis. This low CTE helps minimize thermal stresses and warpage in PCBs, ensuring better reliability and performance stability over a wide temperature range.

RO4350B has a glass transition temperature (Tg) of >280°C and a decomposition temperature of 425°C. These high-temperature characteristics make the material suitable for lead-free solder processes and ensure its stability in demanding thermal environments.

Mechanically, RO4350B offers good rigidity and dimensional stability. The material has a tensile strength of 139 MPa and a flexural strength of 203 MPa, making it capable of withstanding the stresses encountered during PCB fabrication and assembly processes.

Moisture Absorption and Environmental Stability

One of the challenges faced by many PCB materials is moisture absorption, which can lead to degradation of electrical properties and overall performance. RO4350B addresses this issue with its low moisture absorption rate of 0.02% after 24 hours of immersion in water at 23°C. This low moisture absorption ensures that the material maintains its electrical and mechanical integrity even in humid environments.

Furthermore, RO4350B demonstrates excellent environmental stability, with minimal changes in its properties when exposed to harsh conditions. The material is resistant to various chemicals, solvents, and oils commonly encountered in electronic applications. This stability makes RO4350B a reliable choice for applications that require consistent performance in demanding environmental conditions.

Applications of RO4350B

The unique combination of electrical, thermal, and mechanical properties offered by RO4350B makes it suitable for a wide range of high-frequency and microwave applications. Some of the key applications include:

-

Wireless Communication Systems: RO4350B is widely used in the design and fabrication of antennas, filters, and other RF components for wireless communication systems, such as 5G networks, Wi-Fi, and Bluetooth devices.

-

Radar and Satellite Technology: The material’s low dielectric loss and stable performance over a wide frequency range make it an ideal choice for radar systems and satellite communication equipment.

-

Aerospace and Defense: RO4350B’s environmental stability and high-temperature resistance make it suitable for use in aerospace and defense applications, where reliability and performance under harsh conditions are critical.

-

Automotive Electronics: As the automotive industry increasingly incorporates advanced driver assistance systems (ADAS) and vehicle-to-everything (V2X) communication, RO4350B finds applications in automotive radar and connectivity solutions.

-

Internet of Things (IoT) Devices: The growing IoT market requires high-performance, compact, and cost-effective PCB solutions. RO4350B’s properties enable the design of miniaturized, high-frequency IoT devices with reliable performance.

Processing and Fabrication Considerations

When working with RO4350B, there are several processing and fabrication considerations to keep in mind. The material is compatible with standard PCB fabrication processes, such as drilling, milling, and etching. However, due to its unique composition, some adjustments to the fabrication parameters may be necessary to achieve optimal results.

For drilling, it is recommended to use carbide drills with high helix angles and sharp cutting edges to minimize smearing and burring. The use of entry and exit materials, such as aluminum or phenolic sheets, can help reduce surface damage and improve hole quality.

During the etching process, it is essential to control the etching parameters, such as the etchant concentration, temperature, and agitation, to ensure consistent and accurate feature sizes. The use of high-quality photoresists and proper exposure and development techniques can help achieve well-defined circuit patterns.

Proper handling and storage of RO4350B laminates are also crucial to maintain their quality and performance. The laminates should be stored in a cool, dry place, away from direct sunlight and sources of heat. When handling the material, it is essential to wear gloves to avoid contamination and minimize the risk of static discharge.

Comparison with Other High-frequency PCB materials

RO4350B is one of several high-frequency PCB materials available in the market. Some of the other popular materials include:

-

RO4003C: Another high-performance laminate from Rogers Corporation, with a slightly lower dielectric constant (3.38) and similar low loss tangent.

-

FR-4: A widely used PCB material, but with higher dielectric loss and lower performance at high frequencies compared to RO4350B.

-

PTFE (Teflon): PTFE-based laminates offer excellent electrical properties but are more expensive and challenging to process compared to RO4350B.

-

Polyimide: Polyimide-based laminates provide good thermal stability and mechanical strength but have higher dielectric loss compared to RO4350B.

When selecting a PCB material for high-frequency applications, designers must consider factors such as the dielectric constant, loss tangent, thermal stability, and cost. RO4350B offers a balanced combination of these properties, making it a popular choice for many applications.

FAQ

- What is the main difference between RO4350B and FR-4?

-

RO4350B is a high-performance laminate material designed for high-frequency applications, while FR-4 is a general-purpose PCB material. RO4350B has a lower dielectric constant and loss tangent, making it more suitable for applications that require low signal loss and high signal integrity.

-

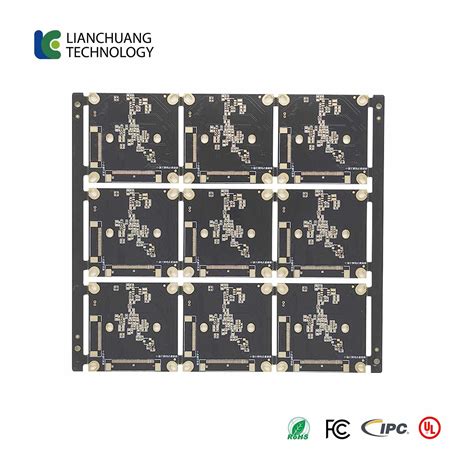

Can RO4350B be used for multilayer PCBs?

-

Yes, RO4350B can be used for multilayer PCB fabrication. The material’s stable properties and low moisture absorption make it suitable for building reliable, high-performance multilayer structures.

-

Is RO4350B compatible with lead-free solder processes?

-

Yes, RO4350B’s high glass transition temperature (Tg) and decomposition temperature make it compatible with lead-free solder processes, ensuring the material’s stability during assembly.

-

What are the storage requirements for RO4350B laminates?

-

RO4350B laminates should be stored in a cool, dry place, away from direct sunlight and sources of heat. It is recommended to store the laminates in their original packaging until ready for use to minimize the risk of contamination and damage.

-

How does the cost of RO4350B compare to other high-frequency PCB materials?

- RO4350B is generally more expensive than general-purpose PCB materials like FR-4 but is competitively priced compared to other high-frequency laminates. The material’s balanced properties and ease of processing make it a cost-effective choice for many high-frequency applications.

Conclusion

RO4350B is a high-performance PCB material that offers a unique combination of electrical, thermal, and mechanical properties, making it an ideal choice for demanding high-frequency and microwave applications. Its low dielectric constant, low loss tangent, and stable performance over a wide frequency range enable the design and fabrication of reliable, high-performance electronic circuits.

The material’s low moisture absorption, environmental stability, and compatibility with standard PCB fabrication processes further contribute to its versatility and usefulness in various industries, including wireless communications, radar, aerospace, defense, automotive, and IoT.

When working with RO4350B, designers and fabricators must consider the material’s specific processing requirements and follow best practices to ensure optimal results. By understanding the material’s properties and applications, designers can leverage RO4350B’s capabilities to create innovative, high-performance electronic solutions for a wide range of applications.

No responses yet