Introduction to PCB Substrate

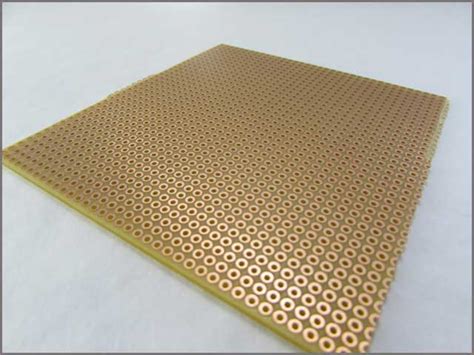

A Printed Circuit Board (PCB) is a fundamental component in modern electronics, serving as the foundation for mounting and connecting various electronic components. The PCB substrate is the base material on which the conductive traces, pads, and other features are printed or etched. The choice of PCB substrate material is crucial as it determines the overall performance, reliability, and cost of the final product. In this article, we will explore the various types of PCB substrate materials, their properties, and their applications.

Types of PCB Substrate Materials

There are several types of PCB substrate materials available, each with its own unique characteristics and benefits. The most common PCB substrate materials include:

1. FR-4

FR-4 (Flame Retardant 4) is the most widely used PCB substrate material. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin binder. FR-4 offers excellent mechanical and electrical properties, making it suitable for a wide range of applications. Some key features of FR-4 include:

- Good Dielectric constant and low dissipation factor

- High mechanical strength and dimensional stability

- Excellent thermal and chemical resistance

- Flame retardant properties

FR-4 is commonly used in consumer electronics, telecommunications equipment, and industrial control systems.

2. Polyimide

Polyimide is a high-performance polymer that offers exceptional thermal and mechanical stability. It is often used in applications that require high reliability and the ability to withstand extreme temperatures. Some advantages of polyimide PCB substrates include:

- High glass transition temperature (Tg) and thermal stability

- Excellent mechanical strength and flexibility

- Low dielectric constant and dissipation factor

- Resistance to chemicals and solvents

Polyimide PCBs are commonly found in aerospace, military, and automotive applications, as well as in high-temperature environments.

3. Ceramic

Ceramic PCB substrates are made from inorganic materials such as alumina (Al2O3) or aluminum nitride (AlN). They offer superior thermal conductivity, high dielectric strength, and low dielectric loss. Some key features of ceramic PCB substrates include:

- Excellent thermal conductivity and heat dissipation

- High mechanical strength and stiffness

- Low dielectric constant and loss tangent

- Resistance to moisture and chemicals

Ceramic PCBs are often used in high-power applications, such as power electronics, RF and microwave devices, and LED lighting.

4. PTFE (Teflon)

PTFE (Polytetrafluoroethylene), also known as Teflon, is a fluoropolymer with exceptional electrical and thermal properties. PTFE PCB substrates offer the lowest dielectric constant and dissipation factor among all PCB Materials. Some advantages of PTFE include:

- Extremely low dielectric constant and dissipation factor

- High thermal stability and chemical resistance

- Excellent moisture resistance

- Low friction and non-stick surface

PTFE PCBs are commonly used in high-frequency applications, such as radar systems, satellite communications, and medical equipment.

Properties of PCB Substrate Materials

When selecting a PCB substrate material, several key properties must be considered to ensure optimal performance and reliability. These properties include:

1. Dielectric Constant (Dk)

The dielectric constant, also known as relative permittivity, is a measure of a material’s ability to store electrical energy. A lower dielectric constant is desirable for high-frequency applications, as it reduces signal propagation delay and minimizes signal loss. Typical dielectric constant values for common PCB substrates are:

| PCB Substrate | Dielectric Constant (Dk) |

|---|---|

| FR-4 | 4.2 – 4.5 |

| Polyimide | 3.4 – 3.5 |

| Ceramic | 8.0 – 10.0 |

| PTFE | 2.1 – 2.3 |

2. Dissipation Factor (Df)

The dissipation factor, also known as loss tangent, is a measure of a material’s ability to dissipate electrical energy as heat. A lower dissipation factor is desirable for high-frequency applications, as it minimizes signal attenuation and power loss. Typical dissipation factor values for common PCB substrates are:

| PCB Substrate | Dissipation Factor (Df) |

|---|---|

| FR-4 | 0.02 – 0.03 |

| Polyimide | 0.002 – 0.003 |

| Ceramic | 0.001 – 0.002 |

| PTFE | 0.0002 – 0.0008 |

3. Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. A higher thermal conductivity is desirable for applications that generate significant heat, as it helps dissipate heat more effectively and prevents component damage. Typical thermal conductivity values for common PCB substrates are:

| PCB Substrate | Thermal Conductivity (W/mK) |

|---|---|

| FR-4 | 0.3 – 0.4 |

| Polyimide | 0.2 – 0.3 |

| Ceramic | 20 – 30 |

| PTFE | 0.2 – 0.3 |

4. Mechanical Strength

Mechanical strength refers to a material’s ability to withstand physical stress and maintain its structural integrity. A higher mechanical strength is desirable for applications that require high reliability and durability. PCB substrates with good mechanical strength include:

- FR-4: High tensile and flexural strength

- Polyimide: Excellent mechanical strength and flexibility

- Ceramic: High mechanical strength and stiffness

Applications of PCB Substrate Materials

The choice of PCB substrate material depends on the specific requirements of the application. Some common applications and their preferred PCB substrate materials include:

1. Consumer Electronics

- FR-4: Cost-effective and suitable for most consumer electronics

- Polyimide: Used in flexible and wearable electronics

2. Telecommunications

- FR-4: Widely used in low-frequency and digital applications

- PTFE: Preferred for high-frequency and RF applications

3. Automotive and Aerospace

- Polyimide: Suitable for high-reliability and high-temperature environments

- Ceramic: Used in power electronics and high-temperature applications

4. Medical Equipment

- FR-4: Used in low-frequency and digital medical devices

- PTFE: Preferred for high-frequency medical imaging and diagnostic equipment

Frequently Asked Questions (FAQ)

1. What is the most commonly used PCB substrate material?

FR-4 is the most widely used PCB substrate material due to its good electrical and mechanical properties, cost-effectiveness, and versatility.

2. Which PCB substrate material is best for high-frequency applications?

PTFE (Teflon) is the preferred PCB substrate material for high-frequency applications due to its extremely low dielectric constant and dissipation factor, which minimize signal loss and attenuation.

3. Which PCB substrate material offers the best thermal conductivity?

Ceramic PCB substrates, such as alumina (Al2O3) and aluminum nitride (AlN), offer the highest thermal conductivity among common PCB substrate materials, making them suitable for high-power and high-temperature applications.

4. Can I use FR-4 for flexible PCBs?

While FR-4 is not suitable for flexible PCBs due to its rigid nature, polyimide is an excellent choice for flexible and wearable electronics thanks to its excellent mechanical strength and flexibility.

5. What factors should I consider when selecting a PCB substrate material?

When selecting a PCB substrate material, consider factors such as the application’s Frequency Range, thermal requirements, mechanical stress, and environmental conditions. Additionally, consider the cost and availability of the material, as well as the manufacturing capabilities of your PCB supplier.

Conclusion

PCB substrate materials play a crucial role in determining the performance, reliability, and cost of electronic devices. Understanding the properties and applications of different PCB substrate materials is essential for designing and manufacturing high-quality PCBs. FR-4, polyimide, ceramic, and PTFE are among the most common PCB substrate materials, each offering unique advantages for specific applications. By carefully considering the requirements of your application and selecting the appropriate PCB substrate material, you can ensure optimal performance and longevity of your electronic products.

No responses yet