Introduction to PCB matching length

In the world of printed circuit board (PCB) design, achieving optimal signal integrity is crucial for ensuring the proper functioning of electronic devices. One key aspect of maintaining signal integrity is through the concept of PCB matching length. This article will delve into the meaning, importance, and implementation of PCB matching length in PCB design.

What is PCB Matching Length?

PCB matching length refers to the practice of ensuring that the lengths of parallel signal traces on a PCB are equal or within a specified tolerance. By maintaining consistent trace lengths, designers can minimize signal skew and ensure that signals arrive at their destinations simultaneously, preventing timing issues and signal degradation.

Why is PCB Matching Length Important?

Matching trace lengths is essential for several reasons:

-

Signal Integrity: When parallel signal traces have varying lengths, signals traveling along these traces may arrive at their destinations at different times. This can lead to signal skew, which can cause timing issues, data corruption, and overall system instability.

-

High-Speed Applications: As the operating frequencies of electronic devices continue to increase, the impact of signal skew becomes more pronounced. In high-speed applications, even small differences in trace lengths can have significant effects on signal integrity.

-

Reducing Electromagnetic Interference (EMI): Mismatched trace lengths can contribute to increased EMI. By ensuring that parallel traces have equal lengths, designers can minimize the radiation of electromagnetic energy and reduce the risk of interference with other components or devices.

Techniques for Achieving PCB Matching Length

There are several techniques that PCB designers can employ to achieve matching trace lengths:

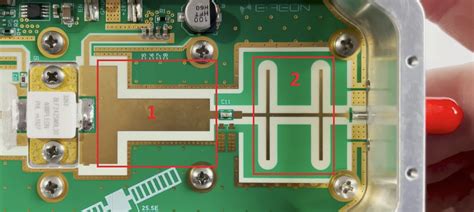

1. Length Matching Using Meanders

One common approach to matching trace lengths is by using meanders. Meanders are intentional serpentine-like patterns added to shorter traces to increase their length and match them with longer traces. By carefully designing meanders, designers can fine-tune trace lengths to achieve the desired matching.

Here’s an example of how meanders can be used to match trace lengths:

| Trace | Length without Meander | Length with Meander |

|---|---|---|

| A | 5 cm | 5 cm |

| B | 4 cm | 5 cm |

| C | 6 cm | 6 cm |

In this example, trace B is shorter than traces A and C. By adding a meander to trace B, its length is increased to match the lengths of traces A and C, ensuring equal signal propagation times.

2. Length Matching Using Delay Lines

Another technique for matching trace lengths is by using delay lines. Delay lines are passive components, such as serpentine traces or lumped elements, that are intentionally added to shorter traces to introduce a controlled delay. By carefully selecting the appropriate delay line components and their values, designers can match the signal propagation times of parallel traces.

3. Length Matching Using PCB Layers

In multi-layer PCBs, designers can leverage different layers to achieve trace length matching. By strategically routing traces on different layers and using vias to transition between layers, designers can equalize the lengths of parallel traces. This technique allows for more flexibility in trace routing and can help optimize board space utilization.

4. Length Matching Using Software Tools

Many modern PCB design software tools offer features specifically designed for trace length matching. These tools can automatically calculate trace lengths, identify mismatches, and suggest modifications to achieve equal lengths. Some software tools even provide advanced algorithms that can optimize trace routing while maintaining matched lengths.

Factors Affecting PCB Matching Length

When implementing PCB matching length, designers must consider several factors that can impact the effectiveness of their efforts:

1. Dielectric Constant

The dielectric constant of the PCB material plays a significant role in signal propagation speed. Different dielectric materials have varying dielectric constants, which affect the velocity of signals traveling through the traces. When selecting PCB materials, designers must consider the dielectric constant and its impact on signal speed to ensure accurate length matching.

2. Trace Width and Thickness

The width and thickness of PCB traces also influence signal propagation speed. Wider and thicker traces have lower resistance and allow signals to travel faster compared to narrower and thinner traces. When matching trace lengths, designers must take into account the variations in trace width and thickness and compensate accordingly.

3. Frequency and Rise Time

The operating frequency and rise time of signals are critical factors in PCB matching length. As frequencies increase and rise times decrease, the impact of trace length mismatches becomes more pronounced. Designers must consider the frequency and rise time requirements of their specific application and ensure that trace lengths are matched appropriately to maintain signal integrity.

4. Impedance Matching

In addition to matching trace lengths, designers must also consider impedance matching. Impedance mismatches can cause signal reflections and distortions, impacting signal integrity. By carefully designing traces and selecting appropriate materials, designers can achieve both length matching and impedance matching to optimize signal quality.

Best Practices for PCB Matching Length

To effectively implement PCB matching length in your designs, consider the following best practices:

-

Plan for Length Matching Early: Incorporate length matching considerations from the initial stages of PCB design. By planning ahead, you can allocate sufficient space for meanders, delay lines, or layer transitions, minimizing the need for extensive modifications later in the design process.

-

Use Consistent Trace Widths: Maintain consistent trace widths for parallel signals whenever possible. Consistent widths help ensure equal signal propagation speeds and simplify length matching efforts.

-

Minimize Vias: While vias are useful for transitioning between layers, they can introduce discontinuities and affect signal integrity. Minimize the use of vias in length-matched traces and ensure that via sizes and locations are consistent across parallel traces.

-

Verify Length Matching: Use PCB design software tools to verify trace lengths and identify any mismatches. Many tools offer built-in length matching verification features that can highlight potential issues and suggest corrections.

-

Perform Signal Integrity Simulations: Conduct signal integrity simulations to analyze the impact of trace length mismatches on your specific design. Simulations can help identify potential issues and allow you to make informed decisions about trace routing and length matching strategies.

FAQ

-

What is the purpose of PCB matching length?

PCB matching length ensures that parallel signal traces have equal or closely matched lengths, minimizing signal skew and ensuring proper signal synchronization. -

How does PCB matching length affect signal integrity?

When trace lengths are not matched, signals traveling along parallel traces may arrive at their destinations at different times, leading to signal skew. This can cause timing issues, data corruption, and overall system instability, compromising signal integrity. -

What are some common techniques for achieving PCB matching length?

Common techniques for achieving PCB matching length include using meanders (serpentine patterns) to equalize trace lengths, employing delay lines to introduce controlled delays, leveraging different PCB layers for trace routing, and utilizing software tools with length matching features. -

How does the dielectric constant of PCB materials affect length matching?

The dielectric constant of PCB materials influences the speed at which signals propagate through the traces. Different dielectric materials have varying dielectric constants, affecting signal velocity. Designers must consider the dielectric constant when matching trace lengths to ensure accurate signal synchronization. -

What are some best practices for implementing PCB matching length in designs?

Best practices for implementing PCB matching length include planning for length matching early in the design process, using consistent trace widths, minimizing the use of vias, verifying length matching using software tools, and performing signal integrity simulations to analyze the impact of trace length mismatches on the specific design.

Conclusion

PCB matching length is a crucial aspect of PCB design that ensures optimal signal integrity and system performance. By equalizing the lengths of parallel signal traces, designers can minimize signal skew, reduce electromagnetic interference, and maintain proper signal synchronization. Techniques such as meanders, delay lines, layer utilization, and software tools can be employed to achieve accurate length matching.

When implementing PCB matching length, designers must consider factors such as dielectric constant, trace width and thickness, operating frequency, and impedance matching. By following best practices and leveraging simulation tools, designers can effectively incorporate length matching into their PCB designs, resulting in robust and reliable electronic systems.

As the demand for high-speed and high-performance electronics continues to grow, the importance of PCB matching length will only increase. By understanding the principles and techniques involved in length matching, PCB designers can create designs that meet the stringent requirements of modern electronic applications while ensuring optimal signal integrity and system functionality.

No responses yet