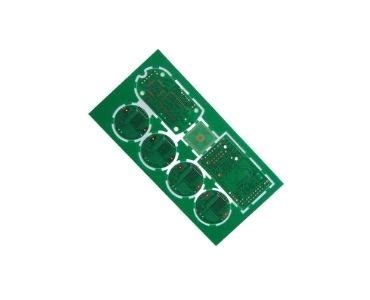

Characteristics of FR1 PCB

Composition and Structure

FR1 PCB is made from a composite material consisting of a paper base impregnated with a phenolic resin. The paper provides the structural support, while the phenolic resin acts as a binder and provides the flame-retardant properties. The copper foil is laminated onto the surface of the FR1 substrate to create the conductive layer for the circuit.

Flame Retardancy

The flame-retardant properties of FR1 PCB are achieved through the use of the phenolic resin. When exposed to heat or flame, the resin undergoes a chemical reaction that releases non-flammable gases and chars, creating a barrier that slows down the spread of the fire. However, it is important to note that FR1 PCB offers only basic flame resistance and may not be suitable for applications with stringent fire safety requirements.

Electrical and Mechanical Properties

FR1 PCB has relatively low dielectric constant and dissipation factor, making it suitable for low-frequency applications. However, its electrical properties are not as good as those of higher-grade PCB materials like FR4. The mechanical strength and dimensional stability of FR1 PCB are also lower compared to other materials, which limits its use in applications that require high precision or are subject to mechanical stress.

Applications of FR1 PCB

Consumer Electronics

FR1 PCB is commonly used in low-cost consumer electronics, such as:

– Toys

– Remote controls

– Calculators

– Basic electronic devices

These applications typically have lower performance requirements and do not require advanced flame retardancy.

Low-Power Applications

FR1 PCB is suitable for low-power applications where the circuitry does not generate significant heat. Examples include:

– LED lighting control boards

– Simple power supply units

– Basic sensor boards

Prototyping and Educational Projects

Due to its low cost and ease of manufacturing, FR1 PCB is often used for prototyping and educational projects. It allows students and hobbyists to create simple circuits and learn about PCB design and fabrication.

Manufacturing Process of FR1 PCB

Substrate Preparation

The manufacturing process of FR1 PCB begins with the preparation of the substrate. The paper base is impregnated with the phenolic resin and then dried and cured to create a solid, flame-retardant material.

Copper Foil Lamination

The copper foil is laminated onto the surface of the FR1 substrate using heat and pressure. The copper foil is typically available in various thicknesses, depending on the current carrying requirements of the circuit.

Circuit Pattern Transfer

The desired circuit pattern is transferred onto the copper foil using a photolithographic process. A photoresist layer is applied to the copper surface, and then the circuit pattern is exposed and developed.

Etching and Drilling

The unwanted copper is removed through an etching process, leaving only the desired circuit pattern. Holes are drilled through the board to accommodate through-hole components and provide interconnections between layers.

Solder Mask and Silkscreen Application

A solder mask layer is applied to the board to protect the copper traces from oxidation and prevent solder bridges during the assembly process. The silkscreen layer is then added to provide text and symbols for component placement and identification.

Surface Finish

Finally, a surface finish, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), is applied to the exposed copper pads to improve solderability and protect the copper from oxidation.

Comparison with Other PCB Materials

FR4 PCB

FR4 PCB is a higher-grade material compared to FR1 PCB. It is made from a glass-reinforced epoxy laminate and offers better electrical, mechanical, and thermal properties. FR4 PCB is the most widely used material for high-performance applications and is suitable for multi-layer designs. However, it is more expensive than FR1 PCB.

CEM-1 PCB

CEM-1 PCB is a composite material that combines a paper core with a glass-reinforced epoxy surface. It offers better mechanical and electrical properties than FR1 PCB but is not as good as FR4 PCB. CEM-1 PCB is often used as a cost-effective alternative to FR4 PCB in applications where the performance requirements are not as demanding.

Aluminum PCB

Aluminum PCB uses an aluminum substrate instead of the traditional FR1 or FR4 materials. It offers excellent thermal dissipation properties, making it suitable for applications that generate significant heat, such as power electronics and LED lighting. However, aluminum PCB is more expensive and requires specialized manufacturing processes.

Advantages and Disadvantages of FR1 PCB

Advantages

- Low cost: FR1 PCB is one of the most affordable PCB materials available, making it suitable for cost-sensitive applications.

- Easy to manufacture: The manufacturing process for FR1 PCB is relatively simple and does not require specialized equipment or processes.

- Suitable for low-frequency applications: FR1 PCB has acceptable electrical properties for low-frequency applications.

- Flame retardant: FR1 PCB offers basic flame resistance, which is sufficient for many consumer electronics applications.

Disadvantages

- Limited performance: FR1 PCB has lower electrical, mechanical, and thermal properties compared to higher-grade materials like FR4 PCB.

- Not suitable for high-frequency applications: The electrical properties of FR1 PCB are not suitable for high-frequency applications, such as RF and microwave circuits.

- Limited multi-layer capabilities: FR1 PCB is not ideal for multi-layer designs due to its lower dimensional stability and bonding strength between layers.

- Basic flame retardancy: While FR1 PCB is flame retardant, it may not meet the requirements for applications with stringent fire safety standards.

Frequently Asked Questions (FAQ)

1. What does FR1 stand for in FR1 PCB?

FR1 stands for Flame Retardant 1, indicating that the PCB material offers basic flame resistance properties.

2. Is FR1 PCB suitable for high-frequency applications?

No, FR1 PCB is not suitable for high-frequency applications due to its limited electrical properties. For high-frequency applications, higher-grade materials like FR4 PCB are recommended.

3. Can FR1 PCB be used for multi-layer designs?

While it is possible to create multi-layer designs with FR1 PCB, it is not ideal due to its lower dimensional stability and bonding strength between layers. FR4 PCB is a better choice for multi-layer designs.

4. Is FR1 PCB more expensive than FR4 PCB?

No, FR1 PCB is generally less expensive than FR4 PCB. FR1 PCB is one of the most affordable PCB materials available, making it suitable for cost-sensitive applications.

5. What are the typical applications for FR1 PCB?

FR1 PCB is commonly used in low-cost consumer electronics, such as toys, remote controls, calculators, and basic electronic devices. It is also suitable for low-power applications, prototyping, and educational projects.

Conclusion

FR1 PCB is a cost-effective solution for applications that require basic flame resistance and have lower performance requirements. Its affordability and ease of manufacturing make it a popular choice for consumer electronics, low-power applications, and prototyping. However, it is important to understand the limitations of FR1 PCB, such as its lower electrical, mechanical, and thermal properties compared to higher-grade materials like FR4 PCB. When selecting a PCB material, designers should carefully consider the specific requirements of their application and choose the material that offers the best balance of performance, cost, and manufacturability.

No responses yet