Introduction to Four-Terminal Sensing

Four-terminal sensing, also known as 4-wire or Kelvin sensing, is an electrical impedance measuring technique that uses separate pairs of current-carrying and voltage-sensing electrodes to make more accurate measurements than the simpler and more usual two-terminal (2T) sensing. Four-terminal sensing is used in some ohmmeters and impedance analyzers, and in wiring for strain gauges and resistance thermometers. In particular, this measurement approach is critical for low-resistance measurement applications such as advanced printed circuit board (PCB) characterization.

Four-terminal sensing eliminates the lead and contact resistance from the measurement. This is an advantage for precise measurement of low resistance values ranging from 1 Ω down to the low milliohm range. In contrast, two-terminal sensing is subject to lead resistance, contact resistance of the wires, and the contact resistance of the connection points. The typical two-wire approach lumps all these extraneous resistances together with the resistance being measured, severely impacting or entirely dominating the final measurement result when attempting to measure very low resistances.

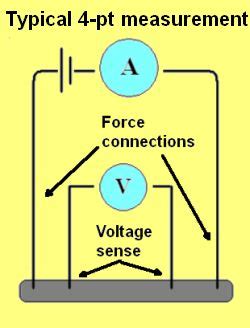

How Four-Terminal Sensing Works

In four-terminal sensing, four wires are used to connect the resistance under test (Rut) to the measuring instrument:

- Two wires (the “source” leads) supply the test current (I)

- Two wires (the “sense” leads) measure the voltage drop (V) across the resistance under test

The key aspect is that the sense wires are connected as close as possible to the resistance under test, so that they do not include the resistance of the source leads in the voltage measurement. Since the sense leads carry very minimal current (just enough to make the voltage measurement), their resistance does not appreciably affect the measurement either.

The measuring instrument can then determine the resistance using Ohm’s law:

R = V / I

Where:

– R is the resistance being measured (Rut)

– V is the voltage measured by the sense wires

– I is the current through the source wires

Four-Terminal Sensing Connection Diagram

A generic 4-wire resistance measurement setup looks like this:

+--------------+

| |

[Source +] [Sense +]

| |

+-----+--------------+-----+

| | R_ut | |

+-----+--------------+-----+

| |

[Source -] [Sense -]

| |

+--------------+

The key points are:

- The sense leads are connected as close as possible to Rut

- The sense leads carry minimal current, so their resistance doesn’t affect the measurement

- The source lead resistances are not included in the voltage measurement, so they don’t affect the Rut calculation

Benefits of Four-Terminal Sensing for Low Resistance Measurement

The main benefit of four-terminal sensing is the ability to accurately measure very low resistances, even when the connecting wires have a much higher resistance. This is crucial for applications like:

- Measuring milliohm shunts for current sensing

- Characterizing low-value current sense resistors

- Testing PCB trace resistances

- Qualifying high-current PCB interconnections like power planes and bus bars

Two-wire connections simply cannot provide the required accuracy for these low-resistance applications due to errors from the test lead resistance.

Comparison of 2-Wire vs 4-Wire Resistance Measurement Accuracy

To illustrate the difference, consider trying to measure a 10 mΩ resistor using test leads that have 100 mΩ of resistance each:

| Measurement Method | Measured Resistance | % Error |

|---|---|---|

| 2-Wire | 210 mΩ | 2000% |

| 4-Wire | 10 mΩ | 0% |

The 2-wire method includes the 200 mΩ of lead resistance, completely swamping the actual 10 mΩ resistance under test. The 4-wire method eliminates the effect of the lead resistance.

Four-Terminal Sensing for Advanced PCB Applications

Four-terminal sensing really shines when applied to characterizing modern PCBs with very low trace resistances and high-current interconnects. Some key applications include:

Measuring Controlled Impedance PCB Traces

Many high-speed digital and RF PCB designs require tightly controlled trace impedances, often 50 Ω or 100 Ω. Four-terminal sensing allows direct milliohm-level measurements of PCB trace resistance, which is a key parameter in calculating the overall trace impedance.

Qualifying High-Current PCB Power Planes

High-current PCB power planes and polygons require very low resistance to minimize I2R losses and voltage drop. Four-terminal sensing is the only way to accurately measure these sub-milliohm resistances in the presence of higher-resistance probing connections.

Characterizing PCB Interconnects and Vias

PCB vias, especially high-aspect-ratio microvias, can have resistances in the milliohm range. Four-terminal sensing allows designers to accurately characterize via resistance to ensure adequate current carrying capacity and minimize voltage drops.

Implementing Four-Terminal Sensing in PCB Test Systems

To take advantage of four-terminal sensing for PCB testing, the PCB must be designed with appropriate test points for the 4-wire connections. This includes:

- Placing dedicated test pads or vias for the 4-wire connections as close as possible to the resistance being measured

- Ensuring there is a current path through the resistance under test when the test points are probed

- Choosing a 4-wire capable resistance meter or impedance analyzer with adequate resolution and accuracy for the expected resistance values

Many modern PCB automatic test equipment (ATE) systems and flying probe testers support 4-wire measurements for this type of advanced PCB characterization.

Conclusion

Four-terminal sensing is a powerful resistance measurement technique that eliminates errors due to test lead and contact resistances. This makes it uniquely suited for measuring the milliohm and microohm-level resistances found in advanced PCB applications like controlled impedance traces, high-current power planes, and microvias.

By designing appropriate 4-wire test points into the PCB and using 4-wire capable test equipment, PCB designers and manufacturers can accurately characterize and qualify these low-resistance features. This allows for improved reliability, performance, and yield in cutting-edge, high-performance PCB applications.

Frequently Asked Questions (FAQ)

1. What is the difference between two-terminal and four-terminal sensing?

Two-terminal sensing uses a single pair of leads for both sourcing current and measuring voltage, while four-terminal sensing uses separate pairs of current and voltage leads. Four-terminal sensing eliminates lead and contact resistance errors, making it much more accurate for low-resistance measurements.

2. What is the typical resistance range that requires four-terminal sensing?

Four-terminal sensing is typically used for resistances from about 1 Ω down to the microohm range. Above 1 Ω, the lead resistance errors of two-terminal sensing become less significant.

3. Can I use four-terminal sensing to measure PCB trace impedance?

Yes, four-terminal sensing can measure the resistance component of a PCB trace’s impedance very accurately. However, for a complete impedance measurement, you also need to characterize the trace’s inductance and capacitance at the frequency of interest.

4. What test equipment do I need for four-terminal PCB measurements?

You need a resistance meter or impedance analyzer with four-wire measurement capability and adequate resolution and accuracy for your expected resistance range. You also need a way to make the 4-wire connection to your PCB, which could be a dedicated test fixture or a 4-wire capable flying probe tester, depending on your PCB design and testing requirements.

5. What are some best practices for designing a PCB for four-terminal testing?

Some key best practices include placing dedicated 4-wire test points as close as possible to the resistance you want to measure, ensuring a current path through the resistance under test, and specifying the 4-wire test points and resistance limits in your PCB test plan. It’s also a good idea to involve your PCB manufacturer and testing provider early in the design process to ensure your PCB can be efficiently tested with their equipment and processes.

No responses yet