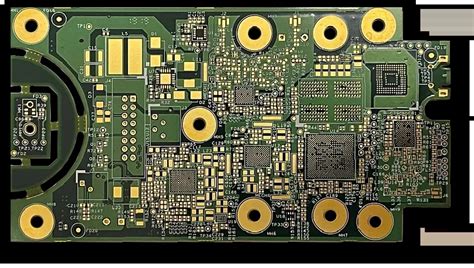

Introduction to HDI PCB

High Density Interconnect (HDI) PCBs are a type of printed circuit board that offers higher density and smaller feature sizes compared to traditional PCBs. HDI PCBs are designed to meet the demands of advanced electronic devices that require high performance, miniaturization, and increased functionality. These boards are characterized by their fine pitch components, high layer counts, and microvias, which enable them to achieve higher interconnect density and improved signal integrity.

Key Features of HDI PCBs

- Fine pitch components

- High layer counts

- Microvias

- Thin dielectric layers

- Controlled impedance

Structure of HDI PCBs

Layers and Stack-up

HDI PCBs typically consist of multiple layers, ranging from 4 to 16 or more, depending on the complexity of the design. The stack-up of an HDI PCB is carefully engineered to ensure optimal signal integrity and minimize crosstalk. A typical HDI PCB stack-up may include:

- Signal layers

- Ground planes

- Power planes

- Dielectric layers

Signal Layers

Signal layers are responsible for carrying the electrical signals between components on the PCB. In HDI PCBs, signal layers are often designed with fine pitch traces and spacing to accommodate the high density of components.

Ground and Power Planes

Ground and power planes are used to distribute power and provide a stable reference for the signals. These planes help to reduce noise and improve signal integrity by minimizing the loop area between the signal traces and the reference planes.

Dielectric Layers

Dielectric layers are used to separate the conductive layers in the PCB stack-up. HDI PCBs often use thin, high-performance dielectric materials to minimize the overall thickness of the board and improve signal integrity.

Microvias

Microvias are small, laser-drilled holes that enable interconnections between layers in an HDI PCB. These vias are typically smaller than 6 mils (0.15 mm) in diameter and can be used to create high-density interconnects between layers. There are three main types of microvias:

- Blind vias: Connect an outer layer to an inner layer

- Buried vias: Connect inner layers to each other

- Through vias: Connect all layers, from top to bottom

| Type of Microvia | Description |

|---|---|

| Blind via | Connects an outer layer to an inner layer |

| Buried via | Connects inner layers to each other |

| Through via | Connects all layers, from top to bottom |

Controlled Impedance

Controlled impedance is a critical aspect of HDI PCB design, particularly for high-speed applications. By carefully controlling the impedance of the signal traces, designers can minimize reflections and ensure proper signal termination. Common controlled impedance structures include:

- Single-ended traces

- Differential pairs

- Coplanar waveguides

Manufacturing Process of HDI PCBs

The manufacturing process of HDI PCBs involves several steps that are more complex and precise than those used for traditional PCBs. The key stages in HDI PCB manufacturing include:

- Material selection

- Lamination

- Drilling

- Plating

- Etching

- Solder mask application

- Surface finish

- Electrical testing

Material Selection

Selecting the appropriate materials for an HDI PCB is crucial for ensuring its performance and reliability. The primary materials used in HDI PCBs include:

- Copper foil for conductive layers

- High-performance dielectric materials, such as polyimide or liquid crystal polymer (LCP)

- Prepreg for bonding layers together

Lamination

Lamination is the process of bonding the individual layers of the PCB together under high temperature and pressure. In HDI PCBs, the lamination process must be carefully controlled to ensure the proper alignment of layers and to minimize the risk of defects.

Drilling

Drilling in HDI PCBs involves the creation of microvias using laser drilling techniques. Laser drilling allows for the creation of small, precise holes that enable high-density interconnects between layers.

Plating

After drilling, the microvias and through-holes are plated with copper to establish electrical connections between layers. The plating process must be carefully controlled to ensure uniform coverage and to avoid defects.

Etching

Etching is the process of removing unwanted copper from the PCB to create the desired circuit patterns. In HDI PCBs, the etching process must be highly precise to achieve the fine pitch traces and spacing required for high-density designs.

Solder Mask Application

A solder mask is applied to the PCB to protect the copper traces from oxidation and to prevent solder bridges during the assembly process. The solder mask must be applied with high precision to ensure that it does not interfere with the fine pitch components and microvias.

Surface Finish

The surface finish is applied to the exposed copper areas of the PCB to protect them from oxidation and to enhance solderability. Common surface finishes for HDI PCBs include:

- Immersion gold (ENIG)

- Electroless nickel immersion gold (ENIG)

- Organic solderability preservative (OSP)

Electrical Testing

After the manufacturing process is complete, HDI PCBs undergo rigorous electrical testing to ensure that they meet the specified performance requirements. This testing may include:

- Continuity testing

- Insulation resistance testing

- High-potential (hipot) testing

- Impedance testing

Applications of HDI PCBs

HDI PCBs are used in a wide range of applications that require high performance, miniaturization, and increased functionality. Some of the most common applications include:

- Smartphones and tablets

- Wearable devices

- Medical devices

- Aerospace and defense systems

- High-performance computing

Smartphones and Tablets

HDI PCBs are essential for enabling the advanced features and compact designs of modern smartphones and tablets. These devices require high-density interconnects to accommodate the numerous components and functions within a small form factor.

Wearable Devices

Wearable devices, such as smartwatches and fitness trackers, rely on HDI PCBs to achieve their compact sizes and advanced features. HDI technology enables the integration of multiple sensors, wireless connectivity, and display drivers within a small, lightweight package.

Medical Devices

HDI PCBs are used in various medical devices, such as implantable devices, diagnostic equipment, and monitoring systems. The high density and reliability of HDI technology enable the development of compact, high-performance medical devices that can improve patient care and outcomes.

Aerospace and Defense Systems

HDI PCBs are used in aerospace and defense systems that require high reliability, performance, and resistance to harsh environments. These applications often demand custom HDI designs that can withstand extreme temperatures, vibrations, and electromagnetic interference.

High-Performance Computing

HDI PCBs are essential for high-performance computing applications, such as servers, workstations, and data centers. The high-density interconnects and controlled impedance of HDI technology enable the development of high-speed, low-latency systems that can process vast amounts of data.

Advantages of HDI PCBs

HDI PCBs offer several advantages over traditional PCBs, including:

-

Miniaturization: HDI technology enables the development of compact, high-density designs that can accommodate advanced features and functions within a small form factor.

-

Improved signal integrity: The controlled impedance and reduced loop areas of HDI PCBs help to minimize noise, crosstalk, and signal reflections, resulting in improved signal integrity and overall system performance.

-

Increased reliability: The use of microvias and high-performance materials in HDI PCBs contributes to increased reliability and durability, even in harsh environments.

-

Lower power consumption: The shorter signal paths and reduced parasitic capacitance of HDI PCBs can lead to lower power consumption, which is particularly important for battery-powered devices.

-

Faster time-to-market: The use of HDI technology can help to streamline the design and manufacturing process, enabling faster prototyping and shorter time-to-market for new products.

Challenges and Considerations in HDI PCB Design and Manufacturing

While HDI PCBs offer numerous benefits, there are also several challenges and considerations that designers and manufacturers must address:

-

Design complexity: HDI PCBs require advanced design tools and expertise to ensure proper signal integrity, thermal management, and manufacturability.

-

Manufacturing complexity: The manufacturing process for HDI PCBs is more complex and precise than that of traditional PCBs, requiring specialized equipment and expertise.

-

Cost: The advanced materials, processes, and equipment used in HDI PCB manufacturing can result in higher costs compared to traditional PCBs.

-

Supply chain management: The specialized materials and components used in HDI PCBs may require careful supply chain management to ensure availability and consistency.

-

Testing and validation: HDI PCBs require rigorous testing and validation to ensure that they meet the specified performance requirements and can withstand the intended operating conditions.

Future Trends in HDI PCB Technology

As electronic devices continue to advance and evolve, HDI PCB technology will play an increasingly important role in enabling new features, functionalities, and form factors. Some of the key trends and developments in HDI PCB technology include:

-

Increased layer counts and density: Future HDI PCBs are likely to feature even higher layer counts and interconnect densities to accommodate the growing complexity of electronic systems.

-

Advanced materials: The development of new, high-performance materials, such as ultra-low loss dielectrics and advanced copper alloys, will enable the creation of HDI PCBs with improved signal integrity and thermal management.

-

Embedded components: The integration of passive components, such as resistors and capacitors, directly into the PCB substrate will help to further reduce the size and improve the performance of HDI PCBs.

-

3D packaging: The use of 3D packaging techniques, such as package-on-package (PoP) and system-in-package (SiP), will enable the development of even more compact and highly integrated electronic systems.

-

Flexible and stretchable HDI PCBs: The development of flexible and stretchable HDI PCBs will enable new applications in wearable devices, medical implants, and other fields that require conformable electronics.

Conclusion

HDI PCBs are a critical technology for enabling the advanced features, miniaturization, and high performance of modern electronic devices. By offering higher interconnect density, improved signal integrity, and increased reliability, HDI PCBs are essential for a wide range of applications, from smartphones and wearables to medical devices and aerospace systems.

As electronic systems continue to evolve and become more complex, HDI PCB technology will play an increasingly important role in enabling new functionalities and form factors. Through advancements in materials, manufacturing processes, and packaging techniques, HDI PCBs will continue to push the boundaries of what is possible in electronic design and performance.

Frequently Asked Questions (FAQ)

-

What is the difference between HDI PCBs and traditional PCBs?

HDI PCBs offer higher interconnect density, smaller feature sizes, and improved signal integrity compared to traditional PCBs. They achieve this through the use of microvias, fine pitch components, and advanced materials. -

What are the main applications of HDI PCBs?

HDI PCBs are used in a wide range of applications that require high performance, miniaturization, and increased functionality, such as smartphones, wearable devices, medical devices, aerospace systems, and high-performance computing. -

What are microvias, and why are they important in HDI PCBs?

Microvias are small, laser-drilled holes that enable interconnections between layers in an HDI PCB. They are typically smaller than 6 mils (0.15 mm) in diameter and are essential for achieving high-density interconnects and compact designs. -

What are the main challenges in designing and manufacturing HDI PCBs?

The main challenges in HDI PCB design and manufacturing include design complexity, manufacturing complexity, cost, supply chain management, and testing and validation. Addressing these challenges requires advanced tools, expertise, and processes. -

What are some of the future trends in HDI PCB technology?

Future trends in HDI PCB technology include increased layer counts and density, advanced materials, embedded components, 3D packaging, and flexible and stretchable HDI PCBs. These developments will enable new applications and push the boundaries of electronic design and performance.

No responses yet