Understanding the Basics of PCB Layers

What is a PCB Layer?

A PCB layer refers to the number of conductive copper layers that are used in the construction of a printed circuit board. The number of layers in a PCB can vary from one to multiple layers, depending on the complexity and requirements of the electronic circuit.

Types of PCB Layers

PCBs can be classified based on the number of layers they contain:

- Single Layer (1 Layer) PCB

- Double Layer (2 Layer) PCB

- Multi-Layer PCB (4, 6, 8, or more layers)

Advantages of 1 Layer PCBs

Cost-Effectiveness

One of the primary advantages of using a 1 layer PCB is its cost-effectiveness. Single layer PCBs are the most affordable option among all PCB Types due to their simple construction and minimal material requirements. This makes them an attractive choice for budget-conscious projects and mass-produced consumer electronics.

Simplicity in Design

1 layer PCBs have a straightforward design process compared to multi-layer boards. With only one conductive layer to work with, designers can create simple circuit layouts without the need for complex routing or via placement. This simplicity in design translates to faster turnaround times and reduced chances of errors during the manufacturing process.

Ease of Fabrication

The manufacturing process for 1 layer PCBs is relatively simple and quick. Since there is only one conductive layer, the fabrication process involves fewer steps compared to multi-layer boards. This results in shorter lead times and lower production costs, making 1 layer PCBs an ideal choice for rapid prototyping and small-scale production runs.

Improved Reliability

In some cases, 1 layer PCBs can offer improved reliability compared to multi-layer boards. With fewer layers and a simpler construction, there are fewer potential points of failure in a single layer PCB. This can lead to increased durability and longer product life, especially in applications where the circuit is not exposed to harsh environmental conditions.

Limitations of 1 Layer PCBs

Limited Routing Options

One of the main limitations of 1 layer PCBs is the restricted routing options available. With only one conductive layer, designers must carefully plan the placement of components and traces to avoid overlapping or crossing paths. This limitation can make it challenging to route complex circuits or high-density designs on a single layer board.

Reduced Circuit Density

Due to the limited routing options, 1 layer PCBs typically have a lower circuit density compared to multi-layer boards. This means that fewer components can be accommodated on a single layer PCB of a given size. For projects that require a high component count or compact form factor, a multi-layer PCB may be a more suitable choice.

Electromagnetic Interference (EMI) Concerns

Single layer PCBs can be more susceptible to electromagnetic interference (EMI) compared to multi-layer boards. Without the shielding provided by additional layers, the traces on a 1 layer PCB are more exposed to external electromagnetic fields. This can lead to signal integrity issues and increased noise in the circuit, particularly in high-frequency applications.

Power Distribution Challenges

Distributing power evenly across a 1 layer PCB can be challenging, especially in designs with high current requirements. The limited routing options and the absence of dedicated power planes can result in voltage drops and uneven power distribution, which can adversely affect the performance and reliability of the circuit.

Applications of 1 Layer PCBs

Despite their limitations, 1 layer PCBs find use in a wide range of applications, particularly in simple and cost-sensitive projects. Some common applications include:

-

Consumer Electronics: Simple devices such as calculators, toys, and small appliances often utilize 1 layer PCBs to keep production costs low.

-

Prototype Development: Single layer PCBs are frequently used in the early stages of product development for proof-of-concept and initial testing.

-

Educational Purposes: Due to their simplicity and affordability, 1 layer PCBs are often used in educational settings to teach students about electronic circuits and PCB design.

-

Low-Power Devices: Devices with low power requirements, such as LED lighting systems and simple sensors, can often be implemented using 1 layer PCBs.

Designing 1 Layer PCBs

When designing a 1 layer PCB, there are several key considerations to keep in mind:

-

Component Placement: Carefully plan the placement of components to minimize the crossing of traces and optimize the use of available space.

-

Trace Width and Spacing: Ensure that the trace widths are sufficient to handle the expected current flow and that the spacing between traces meets the minimum requirements to avoid short circuits.

-

Grounding: Provide adequate grounding for the circuit by creating a solid ground plane on the non-component side of the board.

-

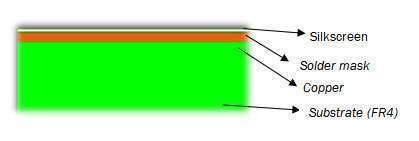

Solder Mask and Silkscreen: Use solder mask to protect the copper traces from oxidation and accidental short circuits. Add silkscreen labels to clearly identify components and their orientations.

Manufacturing Process for 1 Layer PCBs

The manufacturing process for 1 layer PCBs typically involves the following steps:

-

PCB Design: The circuit is designed using PCB design software, and the output files (Gerber and drill files) are generated.

-

PCB Fabrication: The PCB is fabricated by etching the copper layer to create the desired traces and pads. Holes are drilled for through-hole components, and solder mask and silkscreen are applied.

-

Component Placement: The components are placed on the PCB, either manually or using automated pick-and-place machines.

-

Soldering: The components are soldered to the PCB using techniques such as wave soldering or reflow soldering.

-

Inspection and Testing: The assembled PCB undergoes visual inspection and electrical testing to ensure proper functionality and quality.

Frequently Asked Questions (FAQ)

-

Q: What is the minimum trace width for a 1 layer PCB?

A: The minimum trace width depends on the PCB manufacturer and the capabilities of their equipment. Typically, the minimum trace width for a 1 layer PCB ranges from 0.006 inches (0.15 mm) to 0.010 inches (0.25 mm). -

Q: Can 1 layer PCBs have plated through-holes?

A: Yes, 1 layer PCBs can have plated through-holes. The holes are drilled and then plated with a conductive material, allowing for the connection of components on both sides of the board. -

Q: Are 1 layer PCBs suitable for high-frequency applications?

A: Generally, 1 layer PCBs are not recommended for high-frequency applications due to their susceptibility to electromagnetic interference (EMI) and signal integrity issues. For high-frequency applications, multi-layer PCBs with dedicated ground and power planes are preferred. -

Q: What is the maximum size of a 1 layer PCB?

A: The maximum size of a 1 layer PCB depends on the capabilities of the PCB manufacturer. Most manufacturers can produce 1 layer PCBs up to 18 inches x 24 inches (457 mm x 610 mm), while some may offer even larger sizes. -

Q: How can I reduce the cost of 1 layer PCBs?

A: To reduce the cost of 1 layer PCBs, consider the following options:- Minimize the board size

- Use standard board thicknesses and materials

- Opt for larger minimum trace widths and spacings

- Choose a lower copper weight

- Order in larger quantities to take advantage of volume discounts

Conclusion

1 layer PCBs, also known as single layer or single-sided PCBs, offer a cost-effective and simple solution for basic electronic projects and low-cost consumer devices. While they have limitations in terms of routing options, circuit density, and EMI performance, they remain a popular choice for applications that prioritize affordability and simplicity.

When designing 1 layer PCBs, it is essential to carefully consider component placement, trace widths and spacings, grounding, and the use of solder mask and silkscreen. By understanding the advantages, limitations, and design considerations of 1 layer PCBs, engineers and hobbyists can effectively leverage this technology to create functional and reliable electronic products.

| PCB Type | Layers | Cost | Complexity | Applications |

|---|---|---|---|---|

| 1 Layer PCB | 1 | Low | Simple | Consumer electronics, prototypes, educational purposes |

| 2 Layer PCB | 2 | Medium | Moderate | More complex designs, improved EMI performance |

| Multi-Layer PCB | 4, 6, 8, or more | High | High | High-density designs, high-frequency applications, advanced electronics |

As the demand for electronic devices continues to grow, 1 layer PCBs will likely remain a vital part of the electronics industry, offering an accessible and affordable entry point for those looking to create simple yet functional electronic products.

No responses yet