Understanding Flame Retardant in Printed Circuit Boards

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, providing a platform for electrical connections and supporting various components. One crucial aspect of PCB manufacturing is ensuring the safety and reliability of these boards, especially in terms of fire resistance. This is where the term “FR” comes into play. In this article, we will explore what FR stands for in PCBs, its significance, and the different types of flame-retardant materials used in PCB manufacturing.

What is FR?

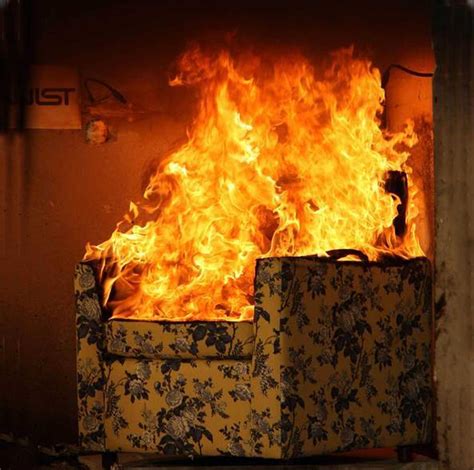

FR is an abbreviation for “Flame Retardant.” In the context of PCBs, FR refers to the materials used in the construction of the board that are designed to resist the spread of fire and minimize the risk of ignition. The use of flame-retardant materials is crucial in ensuring the safety of electronic devices and preventing potential fire hazards.

The Importance of Flame Retardant in PCBs

The incorporation of flame-retardant materials in PCBs is essential for several reasons:

-

Safety: The primary reason for using flame-retardant materials in PCBs is to ensure the safety of users and prevent fire-related accidents. Electronic devices can generate heat during operation, and if a fire were to start, it could quickly spread and cause significant damage. Flame-retardant PCBs help contain the fire and minimize the risk of it spreading to other components or materials.

-

Compliance with Regulations: Many industries have strict regulations and standards regarding the fire safety of electronic devices. For example, the automotive, aerospace, and medical industries require electronic components to meet specific flame-retardant specifications. By using FR materials in PCBs, manufacturers can ensure compliance with these regulations and avoid potential legal and financial consequences.

-

Reliability and Longevity: Flame-retardant PCBs not only provide safety benefits but also contribute to the overall reliability and longevity of electronic devices. By preventing the spread of fire, FR materials help protect the integrity of the PCB and its components, reducing the risk of premature failure and extending the lifespan of the device.

Types of Flame Retardant Materials Used in PCBs

There are several types of flame-retardant materials used in the manufacturing of PCBs. The most common ones include:

-

FR-4: FR-4 is the most widely used flame-retardant material in PCBs. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin. FR-4 offers excellent electrical insulation properties, mechanical strength, and flame resistance. It is suitable for a wide range of applications and is the default choice for most PCB designs.

-

FR-2: FR-2 is a flame-retardant material made of phenolic resin-impregnated paper. It is less expensive compared to FR-4 but also has lower mechanical strength and electrical properties. FR-2 is commonly used in low-end consumer electronics and applications where cost is a primary concern.

-

CEM-1: CEM-1 (Composite Epoxy Material) is a flame-retardant material that combines woven fiberglass and cellulose paper impregnated with epoxy resin. It offers a balance between the properties of FR-4 and FR-2, providing good electrical insulation and mechanical strength at a lower cost compared to FR-4.

-

Halogen-Free Materials: In recent years, there has been a growing trend towards the use of halogen-free flame-retardant materials in PCBs. Traditional flame retardants often contain halogens such as bromine and chlorine, which can release toxic fumes when burned. Halogen-free materials, such as phosphorus-based compounds, provide flame retardancy without the potential environmental and health hazards associated with halogenated materials.

Here’s a table comparing the properties of the common flame-retardant materials used in PCBs:

| Material | Composition | Flame Retardancy | Electrical Properties | Mechanical Strength | Cost |

|---|---|---|---|---|---|

| FR-4 | Woven fiberglass cloth with epoxy resin | Excellent | Excellent | High | High |

| FR-2 | Phenolic resin-impregnated paper | Good | Fair | Low | Low |

| CEM-1 | Woven fiberglass and cellulose paper with epoxy resin | Good | Good | Moderate | Moderate |

| Halogen-Free | Various materials without halogens | Good to Excellent | Good to Excellent | Varies | Varies |

Flame Retardant Standards and Ratings

To ensure the safety and reliability of PCBs, various standards and ratings have been established to classify the flame retardancy of materials. The most widely recognized standard is the Underwriters Laboratories (UL) 94 flammability rating. The UL 94 standard defines several flammability ratings based on the material’s ability to self-extinguish and resist the spread of fire. The common UL 94 ratings for PCBs are:

-

UL 94 V-0: This is the highest rating for flame retardancy. Materials with this rating self-extinguish within 10 seconds after the removal of the flame, and there is no dripping of flaming particles that could ignite cotton placed below the sample.

-

UL 94 V-1: Materials with this rating self-extinguish within 30 seconds after the removal of the flame, and there is no dripping of flaming particles that could ignite cotton placed below the sample.

-

UL 94 V-2: Materials with this rating self-extinguish within 30 seconds after the removal of the flame, but there may be some dripping of flaming particles that could ignite cotton placed below the sample.

It is important to note that the UL 94 ratings are based on specific test conditions and may not fully represent the behavior of materials in real-world fire scenarios. However, they provide a standardized way to compare the flame retardancy of different materials and help manufacturers choose the appropriate materials for their PCB designs.

Frequently Asked Questions (FAQs)

-

What is the difference between FR-4 and FR-2?

FR-4 is a composite material made of woven fiberglass cloth impregnated with epoxy resin, while FR-2 is made of phenolic resin-impregnated paper. FR-4 offers better mechanical strength and electrical properties compared to FR-2, but it is also more expensive. -

Can FR materials completely prevent fires in PCBs?

While FR materials can significantly reduce the risk of fire and minimize the spread of flames, they cannot completely prevent fires from occurring. Other factors, such as proper circuit design, component selection, and manufacturing processes, also play a crucial role in ensuring the fire safety of PCBs. -

Are halogen-free flame-retardant materials better than traditional materials?

Halogen-free flame-retardant materials have gained popularity due to their potential environmental and health benefits. They do not release toxic fumes when burned, making them a safer alternative to traditional halogenated materials. However, the performance and cost of halogen-free materials may vary compared to traditional materials, and the choice ultimately depends on the specific requirements of the application. -

How do I choose the right flame-retardant material for my PCB?

Choosing the right flame-retardant material for your PCB depends on several factors, such as the intended application, required electrical and mechanical properties, cost constraints, and applicable safety standards. It is recommended to consult with PCB manufacturers and materials experts to determine the most suitable material for your specific needs. -

Can flame-retardant materials affect the electrical performance of PCBs?

Flame-retardant materials can have an impact on the electrical performance of PCBs. Some materials may have higher dielectric constants or loss tangents, which can affect signal integrity and high-frequency performance. It is important to consider the electrical properties of the flame-retardant material and design the PCB accordingly to ensure optimal performance.

Conclusion

In conclusion, the FR in PCBs stands for “Flame Retardant,” and it refers to the materials used in the construction of printed circuit boards to resist the spread of fire and minimize the risk of ignition. The use of flame-retardant materials is crucial for ensuring the safety, reliability, and longevity of electronic devices. FR-4 is the most commonly used flame-retardant material in PCBs, offering excellent electrical and mechanical properties. Other materials, such as FR-2, CEM-1, and halogen-free compounds, are also used depending on the specific requirements and constraints of the application.

When selecting a flame-retardant material for a PCB, it is essential to consider factors such as the intended use, required properties, cost, and applicable safety standards. Consulting with PCB manufacturers and materials experts can help determine the most suitable material for a given application.

As technology advances and the demand for safer and more environmentally friendly materials grows, the development of new flame-retardant materials for PCBs is likely to continue. By understanding the importance of FR in PCBs and staying informed about the latest advancements in materials science, manufacturers can design and produce PCBs that meet the highest standards of safety and performance.

No responses yet