Introduction to PCB Materials and FR4

Printed Circuit Boards (PCBs) are essential components in modern electronics, providing a platform for electrical components to be mounted and connected. The choice of PCB material is crucial for ensuring the reliability, performance, and longevity of the electronic device. Among the various PCB materials available, FR4 is one of the most commonly used substrates due to its excellent properties and cost-effectiveness.

What is FR4?

FR4 is a composite material composed of woven fiberglass cloth impregnated with an epoxy resin binder. The “FR” in FR4 stands for “Flame Retardant,” indicating that the material has been treated to resist the spread of flames in case of a fire. The “4” in FR4 represents the specific grade of the material, which is determined by its performance characteristics and manufacturing process.

Properties of FR4

FR4 possesses several desirable properties that make it a popular choice for PCB manufacturing:

- High mechanical strength and durability

- Excellent electrical insulation properties

- Good thermal stability and resistance to high temperatures

- Low moisture absorption

- Flame retardancy

- Cost-effectiveness compared to other PCB materials

Applications of FR4 PCBs

Due to its versatile properties, FR4 is used in a wide range of electronic applications, including:

- Consumer electronics (e.g., smartphones, laptops, televisions)

- Industrial control systems

- Automotive electronics

- Medical devices

- Telecommunications equipment

- Aerospace and defense systems

Understanding the Meaning of “4” in FR4

FR Grades and Their Significance

The “FR” in FR4 stands for “Flame Retardant,” but there are several different grades of flame-retardant materials used in PCB manufacturing. The number following the “FR” indicates the specific grade of the material, which is determined by its performance characteristics and manufacturing process. Some common FR grades include:

| FR Grade | Description |

|---|---|

| FR1 | Paper-based phenolic resin, low-cost, low-performance |

| FR2 | Paper-based phenolic resin, higher quality than FR1 |

| FR3 | Paper-based epoxy resin, better performance than FR1 and FR2 |

| FR4 | Fiberglass-reinforced epoxy resin, high-performance, most common |

| FR5 | Similar to FR4, but with higher glass transition temperature |

| FR6 | Polyester-based material, high-frequency applications |

The Significance of “4” in FR4

The “4” in FR4 specifically refers to the grade of the fiberglass-reinforced epoxy resin material. FR4 is the most commonly used PCB material due to its excellent balance of properties and cost-effectiveness. The “4” indicates that the material meets specific performance criteria outlined in industry standards, such as:

- NEMA (National Electrical Manufacturers Association) LI 1-1998

- IPC (Institute for Interconnecting and Packaging Electronic Circuits) 4101

- MIL-I-24768/27

These standards define the requirements for various properties, such as thermal stability, moisture resistance, and dielectric constant, among others.

Variants of FR4

While FR4 is the most common grade of fiberglass-reinforced epoxy resin PCB material, there are several variants that offer specific advantages for certain applications:

| FR4 Variant | Description |

|---|---|

| FR4-Lead Free | Compatible with lead-free soldering processes |

| High Tg FR4 | Higher glass transition temperature for improved thermal stability |

| Halogen-Free FR4 | Reduces environmental impact and complies with RoHS regulations |

| FR4-HF | High-frequency variant with lower dielectric constant and dissipation factor |

| FR4-Flex | Flexible FR4 material for applications requiring bendable PCBs |

Manufacturing Process of FR4 PCBs

Raw Materials

The main raw materials used in the production of FR4 PCBs are:

- Fiberglass cloth: Provides mechanical strength and dimensional stability

- Epoxy resin: Acts as a binder and provides electrical insulation properties

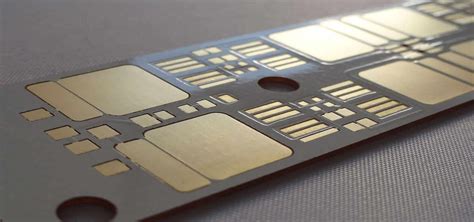

- Copper foil: Used for creating conductive traces and pads on the PCB

Lamination Process

The manufacturing process of FR4 PCBs involves several steps, with lamination being a critical stage:

- The fiberglass cloth is impregnated with the epoxy resin and partially cured to form a prepreg material.

- Layers of prepreg are stacked with copper foil on the outer surfaces and pressed under high temperature and pressure to form a laminated board.

- The copper foil is then patterned and etched to create the desired circuit layout.

Additional Processing Steps

After lamination, the FR4 PCB undergoes several additional processing steps to create the final product:

- Drilling: Holes are drilled through the board for component leads and vias.

- Plating: The drilled holes are plated with copper to create electrical connections between layers.

- Solder mask application: A protective coating is applied to the board, leaving exposed areas for component soldering.

- Silkscreen printing: Text and symbols are printed on the board for component identification and assembly guidance.

- Surface finish application: A protective finish, such as HASL, ENIG, or OSP, is applied to the exposed copper areas to prevent oxidation and improve solderability.

Advantages and Disadvantages of FR4 PCBs

Advantages

- Excellent mechanical strength and durability

- Good electrical insulation properties

- High thermal stability and resistance to high temperatures

- Low moisture absorption

- Flame retardancy

- Cost-effectiveness compared to other PCB materials

- Wide availability and established manufacturing processes

Disadvantages

- Limited high-frequency performance compared to specialized materials like PTFE

- Higher dielectric constant and dissipation factor compared to some other materials

- Not suitable for extreme temperature applications (beyond 140°C)

- May require additional processing for certain applications (e.g., high-frequency, high-speed)

Alternatives to FR4 PCB Materials

While FR4 is the most common PCB material, there are several alternatives that offer specific advantages for certain applications:

| Material | Description | Advantages |

|---|---|---|

| Polyimide | High-temperature resistant material | Suitable for aerospace and military applications |

| PTFE (Teflon) | Low dielectric constant and dissipation factor | Excellent high-frequency performance |

| Rogers Materials | Low dielectric constant and dissipation factor | High-frequency and high-speed applications |

| Ceramic | High thermal conductivity and low CTE | Used in high-power and high-temperature applications |

| Aluminum | Excellent thermal dissipation | Used in LED lighting and power electronics |

Future Trends in PCB Materials

As electronic devices continue to advance and new applications emerge, the development of PCB materials will also evolve. Some future trends in PCB materials include:

-

High-frequency materials: The demand for high-frequency materials, such as low-loss laminates and PTFE-based substrates, will increase as 5G and millimeter-wave applications become more prevalent.

-

Environmentally friendly materials: There will be a growing emphasis on eco-friendly PCB materials that comply with RoHS and REACH regulations, as well as halogen-free and lead-free materials.

-

Flexible and stretchable materials: The rise of wearable electronics and the Internet of Things (IoT) will drive the development of flexible and stretchable PCB materials that can conform to various shapes and withstand repeated bending and stretching.

-

High-thermal conductivity materials: As electronic devices become more compact and powerful, the need for PCB materials with high thermal conductivity will increase to effectively dissipate heat and maintain device performance.

-

Embedded components: The integration of passive components, such as resistors and capacitors, into the PCB substrate will continue to gain traction, enabling smaller, more compact, and cost-effective electronic devices.

Conclusion

FR4 is the most widely used PCB material due to its excellent balance of properties, cost-effectiveness, and widespread availability. The “4” in FR4 represents the specific grade of the fiberglass-reinforced epoxy resin material, which meets strict performance criteria outlined in industry standards. While FR4 is suitable for a wide range of applications, there are several alternatives available for specific requirements, such as high-frequency performance or extreme temperature resistance.

As the electronics industry continues to evolve, the development of new PCB materials will be driven by the demand for high-frequency, environmentally friendly, flexible, and high-thermal conductivity substrates. By understanding the properties and applications of FR4 and other PCB materials, engineers and designers can make informed decisions when selecting the most appropriate substrate for their electronic devices.

FQA

-

Q: What does FR stand for in FR4?

A: FR stands for “Flame Retardant,” indicating that the material has been treated to resist the spread of flames in case of a fire. -

Q: What is the significance of the “4” in FR4?

A: The “4” in FR4 represents the specific grade of the fiberglass-reinforced epoxy resin material, which is determined by its performance characteristics and compliance with industry standards. -

Q: What are some advantages of using FR4 for PCBs?

A: Some advantages of using FR4 for PCBs include excellent mechanical strength and durability, good electrical insulation properties, high thermal stability, low moisture absorption, flame retardancy, and cost-effectiveness compared to other PCB materials. -

Q: Are there any disadvantages to using FR4 PCBs?

A: Some disadvantages of FR4 PCBs include limited high-frequency performance compared to specialized materials like PTFE, higher dielectric constant and dissipation factor compared to some other materials, and unsuitability for extreme temperature applications beyond 140°C. -

Q: What are some alternatives to FR4 for specific PCB applications?

A: Some alternatives to FR4 for specific PCB applications include polyimide for high-temperature resistance, PTFE and Rogers materials for high-frequency performance, ceramic for high-power and high-temperature applications, and aluminum for excellent thermal dissipation in LED lighting and power electronics.

No responses yet