What is FR4 substrate?

FR4 (Flame Retardant 4) is a composite material composed of woven fiberglass cloth with an epoxy resin binder. The “FR” in its name stands for “Flame Retardant,” indicating its inherent resistance to fire. The number “4” represents the specific grade of the material, which is determined by the National Electrical Manufacturers Association (NEMA) standards.

Composition of FR4 substrate

The two main components of FR4 substrate are:

- Woven fiberglass cloth: This provides the structural strength and dimensional stability to the material.

- Epoxy resin: The epoxy resin acts as a binder, holding the fiberglass cloth together and providing insulation properties.

The combination of these materials results in a substrate that possesses excellent mechanical, electrical, and thermal properties.

Properties of FR4 substrate

Mechanical properties

FR4 substrate exhibits outstanding mechanical properties, making it suitable for various applications:

- High tensile strength: FR4 has a tensile strength ranging from 275 to 350 MPa (39,900 to 50,800 psi), ensuring its ability to withstand stress and strain.

- Good flexural strength: The flexural strength of FR4 ranges from 415 to 585 MPa (60,200 to 84,800 psi), allowing it to resist bending and maintain its shape under load.

- Excellent dimensional stability: FR4 maintains its dimensions even under varying environmental conditions, with a low coefficient of thermal expansion (CTE) of 11 to 16 ppm/°C.

| Property | Value Range |

|---|---|

| Tensile Strength | 275 – 350 MPa |

| Flexural Strength | 415 – 585 MPa |

| Coefficient of Thermal Expansion | 11 – 16 ppm/°C |

Electrical properties

FR4 substrate possesses excellent electrical properties, making it suitable for use in PCBs:

- High dielectric strength: FR4 has a dielectric strength of 20 to 28 kV/mm, allowing it to withstand high voltages without breakdown.

- Good insulation resistance: The insulation resistance of FR4 is greater than 10^12 ohms, ensuring minimal current leakage.

- Low dielectric constant: FR4 has a dielectric constant of 4.2 to 4.9 at 1 MHz, which minimizes signal loss and cross-talk between traces.

| Property | Value Range |

|---|---|

| Dielectric Strength | 20 – 28 kV/mm |

| Insulation Resistance | > 10^12 ohms |

| Dielectric Constant (1 MHz) | 4.2 – 4.9 |

Thermal properties

FR4 substrate has good thermal properties, enabling it to function well in various temperature conditions:

- Wide operating temperature range: FR4 can operate between -55°C and 125°C (-67°F to 257°F) without significant degradation in its properties.

- Good thermal conductivity: The thermal conductivity of FR4 ranges from 0.25 to 0.35 W/mK, allowing for efficient heat dissipation.

- Flame retardancy: FR4 is designed to be flame-retardant, with a UL94 V-0 rating, which means it self-extinguishes within 10 seconds after the ignition source is removed.

| Property | Value Range |

|---|---|

| Operating Temperature Range | -55°C to 125°C |

| Thermal Conductivity | 0.25 – 0.35 W/mK |

| UL94 Flammability Rating | V-0 |

Why is FR4 commonly used?

FR4 substrate is widely used in the electronics industry due to its unique combination of properties, which make it suitable for various applications:

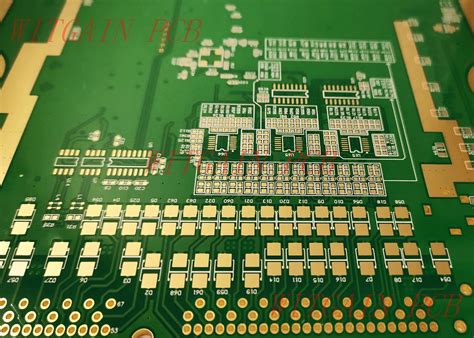

PCB manufacturing

FR4 is the most commonly used substrate material for PCBs due to its:

- Excellent electrical insulation properties

- Good mechanical strength and dimensional stability

- Wide operating temperature range

- Cost-effectiveness compared to other substrate materials

High-frequency applications

FR4 substrate is suitable for high-frequency applications, such as:

- Telecommunications equipment

- Wireless devices

- Radar systems

- Aerospace electronics

Its low dielectric constant and good insulation properties minimize signal loss and cross-talk, ensuring reliable performance in these applications.

Automotive electronics

FR4 substrate is used in automotive electronics due to its:

- Resistance to high temperatures

- Good mechanical strength

- Flame retardancy

These properties ensure the reliability and safety of electronic components in automotive applications.

Consumer electronics

FR4 substrate is widely used in consumer electronics, such as:

- Smartphones

- Laptops

- Tablets

- Gaming consoles

Its cost-effectiveness, good electrical properties, and mechanical strength make it an ideal choice for mass-produced consumer electronics.

FAQ

1. What does FR4 stand for?

FR4 stands for “Flame Retardant 4,” indicating its inherent resistance to fire. The number “4” represents the specific grade of the material, which is determined by the National Electrical Manufacturers Association (NEMA) standards.

2. What are the main components of FR4 substrate?

The two main components of FR4 substrate are woven fiberglass cloth, which provides structural strength and dimensional stability, and epoxy resin, which acts as a binder and provides insulation properties.

3. What is the operating temperature range of FR4 substrate?

FR4 substrate can operate between -55°C and 125°C (-67°F to 257°F) without significant degradation in its properties.

4. Why is FR4 commonly used in PCB manufacturing?

FR4 is commonly used in PCB manufacturing due to its excellent electrical insulation properties, good mechanical strength and dimensional stability, wide operating temperature range, and cost-effectiveness compared to other substrate materials.

5. Is FR4 substrate suitable for high-frequency applications?

Yes, FR4 substrate is suitable for high-frequency applications, such as telecommunications equipment, wireless devices, radar systems, and aerospace electronics. Its low dielectric constant and good insulation properties minimize signal loss and cross-talk, ensuring reliable performance in these applications.

Conclusion

FR4 substrate is a versatile material that has become the go-to choice for various electronics applications due to its unique combination of mechanical, electrical, and thermal properties. Its excellent strength, dimensional stability, insulation properties, and flame retardancy make it suitable for use in PCBs, high-frequency devices, automotive electronics, and consumer products. As technology continues to advance, FR4 substrate remains a reliable and cost-effective solution for the electronics industry.

No responses yet