Key Properties of FR4

The main properties that make FR4 a preferred material choice include:

- High strength and stiffness

- Excellent electrical insulation

- Flame resistance

- Good thermal stability

- Low water absorption

- Excellent chemical resistance

- Low cost compared to other PCB substrates

Let’s examine each of these key FR4 properties in more detail.

High Strength and Stiffness

One of the standout features of FR4 is its high mechanical strength and stiffness. The combination of woven fiberglass cloth and hardened epoxy resin produces a rigid, robust material.

FR4 has a flexural strength ranging from 415-505 MPa (60-73 ksi) depending on the grade and thickness. This allows FR4 to withstand significant bending forces without breaking. Its tensile strength is also high at 310-380 MPa (45-55 ksi).

The stiffness or elastic modulus of FR4 ranges from 15-23 GPa (2200-3300 ksi). This rigidity is important for keeping PCBs flat and preventing warping, especially for high layer count boards. It also provides a stable platform for surface mounted components.

Excellent Electrical Insulation

As a substrate for PCBs, one of the most critical properties of FR4 is its electrically insulating nature. FR4 has very high electrical resistivity and low dielectric losses.

Its Dielectric Breakdown strength is 40-50 kV/mm, meaning it can withstand high voltages without conducting. The dielectric constant of FR4 is quite stable around 4.5-5.0 at frequencies up to 1 GHz. Its dissipation factor measuring dielectric losses is low at 0.015-0.025.

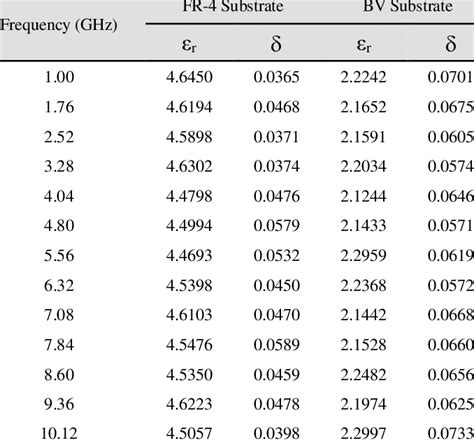

These properties allow FR4 PCBs to electrically isolate conductors and prevent breakdown, cross-talk, and signal losses, even in high frequency applications. The following table summarizes the key electrical properties of FR4:

| Property | Value |

|---|---|

| Dielectric Constant | 4.5-5.0 |

| Dissipation Factor | 0.015-0.025 |

| Dielectric Strength | 40-50 kV/mm |

| Volume Resistivity | 10^14 ohm-cm |

| Surface Resistivity | 10^13 ohm |

Flame Resistance

The “FR” in FR4 stands for “Flame Retardant”, indicating another key property of the material. The epoxy resin used contains flame retardant chemicals, typically bromine compounds, that inhibit ignition and flame spreading.

FR4 is rated UL94 V-0, the highest flame resistance rating. This means FR4 PCBs will self-extinguish within 10 seconds if ignited, without burning through multiple layers. This is a critical safety feature, as it prevents PCBs from causing or spreading fires in devices.

Good Thermal Stability

FR4 has relatively good thermal stability, maintaining its mechanical and electrical properties over a moderate temperature range. The glass transition temperature (Tg) of standard FR4 is around 115-125°C. Some special high-Tg formulations have a Tg up to 180°C.

Below the Tg, the coefficient of thermal expansion (CTE) is low around 10-15 ppm/°C in the XY plane and 30-70 ppm/°C in the Z-axis. Above the Tg, the CTE increases significantly. The thermal conductivity is low around 0.25-0.4 W/mK.

This means FR4 PCBs can operate in environments up to about 100°C continuously without deformation or damage. The low CTE minimizes stresses from thermal expansion mismatches. However, the low thermal conductivity of the material can limit heat dissipation in some high power applications.

Low Water Absorption

Another advantageous property of FR4 is its low water absorption. When exposed to humidity, FR4 will absorb only a small amount of moisture. Water absorption is typically 0.10-0.15% after 24 hour immersion.

Low water absorption is important for PCBs to maintain their dimensions, mechanical strength, and electrical properties in humid environments. Absorbed moisture can cause swelling, delamination, loss of insulation resistance, and even electrochemical migration in extreme cases. FR4’s low moisture uptake mitigates these issues.

Excellent Chemical Resistance

FR4 material exhibits excellent chemical resistance, which is important both for PCB manufacturing processes and end-use environments. It is resistant to a wide variety of chemicals, including:

- Acids (sulfuric, hydrochloric, nitric)

- Bases (sodium hydroxide, potassium hydroxide)

- Organic solvents (alcohols, acetone, TCE)

- Hydrocarbons (gasoline, oils)

- Oxidizers (peroxides, bleach)

This broad chemical resistance allows the use of various chemical processes during PCB fabrication, such as etching, plating, and cleaning, without damaging the substrate material. It also enables the finished PCBs to survive exposure to fuels, lubricants, cleaning agents, and other chemicals in many applications.

Cost Effectiveness

Finally, one of the most significant advantages of FR4 is its relatively low cost compared to other PCB substrate materials. The raw materials (fiberglass and epoxy) are inexpensive and widely available. The manufacturing processes for making copper-clad FR4 laminates and fabricating them into PCBs are also well-established and efficient.

This combination makes FR4 PCBs very economical, especially at high volumes. Competing materials like polyimide, PTFE, and ceramics can offer higher performance in terms of thermal stability, high frequency properties, etc. However, they are typically much more expensive, limiting their use to specialized high-end applications.

The low cost and good all-around performance of FR4 is what has made it the predominant material choice for the vast majority of PCB applications. It offers an excellent balance of properties at an affordable price point.

FAQ

To conclude, here are answers to some frequently asked questions about FR4 properties and applications:

What is the typical thickness of FR4 used in PCBs?

FR4 laminates for PCBs are commonly available in thicknesses from 0.2 mm to 3.2 mm. The most frequently used thicknesses are 0.4 mm (for flexible uses), 0.8 mm, 1.6 mm, and 2.4 mm. Thinner laminates are used for high-density interconnects, while thicker ones provide more mechanical rigidity.

What is the maximum operating temperature for FR4?

The maximum operating temperature for standard FR4 is typically around 120-130°C. Above this temperature, the material begins to soften and lose mechanical strength as it approaches its glass transition temperature. High-Tg FR4 variants are available that can withstand temperatures up to 170-180°C.

Is FR4 suitable for high-frequency applications?

FR4 is acceptable for many applications up to about 1 GHz, including most consumer electronics. Above this frequency, the dielectric losses of FR4 start to become significant. For higher frequencies, lower loss materials like Rogers RO4000 series or PTFE are often used instead. However, using a thinner laminate and advanced circuit designs can allow FR4 to be used at frequencies up to 10 GHz in some cases.

How does the glass weave of FR4 affect circuit performance?

The woven glass fibers in FR4 can have an effect on very high-speed circuits. As signals transition from traveling over glass bundles to epoxy resin pockets, they experience a slight impedance discontinuity. In most cases, this effect is negligible. However, for extremely high-speed digital signals or precise analog circuits, a glass-free material may be preferable to avoid this source of signal integrity issues.

What are some common applications of FR4 besides PCBs?

While PCBs are the primary application for FR4, it is also used in some other areas that leverage its combination of properties. These include:

- Structural components that require high strength and low weight

- Electrical insulators and standoffs

- Mechanical parts requiring thermal stability

- Washers, fasteners, and handles

- Hard, chemically resistant surfaces

In summary, FR4 is an incredibly versatile material with a highly useful set of properties including high strength, excellent insulating characteristics, flame resistance, thermal stability, low water absorption, chemical resistance, and low cost. These properties have made it a mainstay of the electronics industry as the primary substrate material for the vast majority of PCBs. Understanding the key properties of FR4 is essential for anyone involved in designing, manufacturing, or using PCBs and other products incorporating this valuable material.

No responses yet