Introduction to Polyimides

Polyimides are a class of high-performance polymers known for their exceptional thermal stability, mechanical strength, and chemical resistance. These materials have found widespread applications in various industries, including aerospace, electronics, and automotive. In this article, we will explore the advantages and disadvantages of polyimides to provide a comprehensive understanding of their properties and suitability for different applications.

Advantages of Polyimides

1. Thermal Stability

One of the most significant advantages of polyimides is their excellent thermal stability. These materials can withstand high temperatures, typically ranging from 250°C to 400°C (482°F to 752°F), without significant degradation in their mechanical properties. This makes polyimides ideal for applications that require exposure to elevated temperatures, such as in aerospace components, high-temperature wire insulation, and electronic devices.

2. Mechanical Strength

Polyimides exhibit outstanding mechanical properties, including high tensile strength, modulus, and toughness. They have a tensile strength ranging from 70 to 150 MPa (10,000 to 22,000 psi) and a modulus of 2.5 to 4.5 GPa (360,000 to 650,000 psi). These properties make polyimides suitable for applications that require high strength-to-weight ratios, such as in aircraft structures, robotics, and high-performance composites.

3. Chemical Resistance

Polyimides demonstrate excellent chemical resistance to a wide range of solvents, acids, and bases. They are resistant to hydrolysis, oxidation, and radiation, making them suitable for use in harsh chemical environments. This chemical resistance is attributed to the strong intermolecular forces and the stable aromatic structure of polyimides.

4. Electrical Properties

Polyimides possess good electrical insulation properties, with a dielectric constant ranging from 3.2 to 3.6 and a dielectric strength of 22 to 35 kV/mm (560 to 890 V/mil). They also have low dielectric loss and high volume resistivity, making them suitable for use in electronic applications, such as flexible printed circuit boards, wire insulation, and high-temperature capacitors.

5. Dimensional Stability

Polyimides exhibit low coefficients of thermal expansion (CTE), typically ranging from 20 to 50 ppm/°C (11 to 28 ppm/°F). This dimensional stability is crucial for applications that require tight tolerances and minimal warpage, such as in microelectronics packaging and high-precision components.

Disadvantages of Polyimides

1. High Cost

One of the main disadvantages of polyimides is their relatively high cost compared to other polymeric materials. The raw materials used in the synthesis of polyimides, such as aromatic dianhydrides and diamines, are expensive, and the production process is complex and energy-intensive. This limits the widespread use of polyimides in cost-sensitive applications.

2. Processing Challenges

Polyimides are known for their difficulty in processing due to their high glass transition temperatures (Tg) and melt viscosities. The high Tg, typically above 300°C (572°F), requires elevated processing temperatures, which can lead to thermal degradation if not carefully controlled. Additionally, the high melt viscosity can make it challenging to achieve uniform flow and consolidation during molding or extrusion processes.

3. Moisture Absorption

Some polyimides are susceptible to moisture absorption, which can lead to changes in their mechanical and electrical properties. The absorbed moisture can cause plasticization, reducing the glass transition temperature and modulus of the material. It can also increase the dielectric constant and loss, affecting the electrical performance of the material.

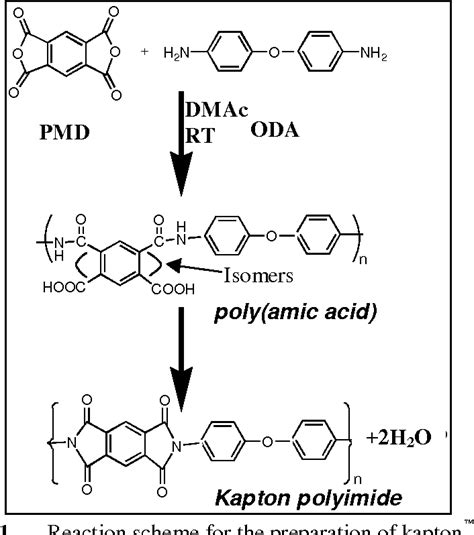

4. Limited Solubility

Most polyimides have limited solubility in common organic solvents, making it challenging to process them using solution-based techniques such as spin coating or solution casting. This limitation is due to the strong intermolecular interactions and the rigid aromatic structure of polyimides. Special solvents, such as N-methyl-2-pyrrolidone (NMP) or dimethylacetamide (DMAc), are often required for dissolving polyimides.

5. UV Sensitivity

Some polyimides are sensitive to ultraviolet (UV) radiation, which can cause degradation and discoloration of the material over time. This UV sensitivity is attributed to the presence of aromatic rings in the polyimide structure, which can absorb UV light and undergo photochemical reactions. UV stabilizers or protective coatings can be used to mitigate this issue in applications that require long-term exposure to sunlight.

Applications of Polyimides

Polyimides find use in a wide range of applications due to their unique combination of properties. Some of the key application areas include:

| Application | Examples |

|---|---|

| Aerospace | Aircraft structures, jet engine components, thermal insulation |

| Electronics | Flexible printed circuit boards, wire insulation, capacitors |

| Automotive | High-temperature hoses, gaskets, seals |

| Medical | Implantable devices, surgical instruments, tubing |

| Oil and Gas | Downhole equipment, seals, gaskets |

| Semiconductors | Interlayer dielectrics, passivation layers, packaging |

| High-temperature Coatings | Cookware, industrial equipment, furnace linings |

Frequently Asked Questions (FAQ)

1. What is the maximum continuous use temperature for polyimides?

The maximum continuous use temperature for polyimides varies depending on the specific type and formulation. Generally, polyimides can withstand temperatures ranging from 250°C to 400°C (482°F to 752°F) without significant degradation in their properties.

2. Are polyimides resistant to all chemicals?

While polyimides exhibit excellent chemical resistance to a wide range of solvents, acids, and bases, they are not resistant to all chemicals. Some strong acids, such as concentrated sulfuric acid, and some highly polar solvents, such as N-methyl-2-pyrrolidone (NMP), can cause swelling or dissolution of polyimides.

3. Can polyimides be used in medical applications?

Yes, certain polyimides are suitable for use in medical applications due to their biocompatibility, chemical resistance, and thermal stability. They are used in implantable devices, surgical instruments, and medical tubing. However, the specific polyimide grade must be selected based on the requirements of the application and must meet the necessary regulatory standards.

4. How do polyimides compare to other high-performance polymers?

Polyimides offer a unique combination of properties that sets them apart from other high-performance polymers. They have higher thermal stability compared to most other polymers, such as polyethylene terephthalate (PET) and polyether ether ketone (PEEK). They also have better mechanical properties and chemical resistance than many other high-temperature polymers, such as polytetrafluoroethylene (PTFE) and polyetherimide (PEI).

5. Can polyimides be recycled?

Recycling polyimides is challenging due to their thermoset nature and the presence of aromatic rings in their structure. Once polyimides are cured, they cannot be easily melted and reshaped like thermoplastic polymers. However, research is ongoing to develop recycling methods for polyimides, such as chemical recycling or incorporation of polyimide waste into other materials as fillers or reinforcements.

Conclusion

Polyimides are a class of high-performance polymers that offer a unique combination of thermal stability, mechanical strength, chemical resistance, and electrical properties. These advantages make them suitable for a wide range of demanding applications in industries such as aerospace, electronics, and automotive. However, polyimides also have some disadvantages, including high cost, processing challenges, moisture absorption, limited solubility, and UV sensitivity.

When considering the use of polyimides for a specific application, it is essential to carefully evaluate the requirements and weigh the advantages and disadvantages. Proper selection of the polyimide grade, processing methods, and design considerations can help optimize the performance and mitigate the limitations of these materials.

As research and development in polyimide chemistry continue, new formulations and processing techniques are being developed to address the challenges and expand the application scope of these high-performance polymers. With their exceptional properties and versatility, polyimides are expected to play an increasingly important role in enabling advanced technologies and innovation across various industries.

No responses yet