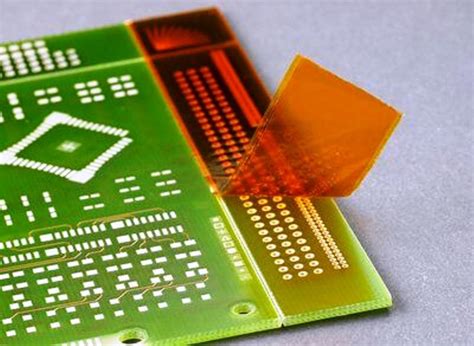

What is PCB Gold Plating?

PCB gold plating is the process of selectively applying a thin layer of gold onto specific areas of a printed circuit board (PCB). Gold plating is used to enhance the electrical conductivity, corrosion resistance, and solderability of the PCB’s surface. The gold layer is typically applied over a nickel underplating to improve adhesion and prevent the diffusion of copper into the gold layer.

Advantages of PCB Gold Plating

-

Enhanced Electrical Conductivity: Gold is an excellent conductor of electricity, making it ideal for high-frequency applications and sensitive electronic devices.

-

Corrosion Resistance: Gold is highly resistant to oxidation and corrosion, ensuring the longevity and reliability of the PCB’s surface.

-

Improved Solderability: Gold-plated surfaces provide excellent solderability, ensuring strong and reliable solder joints.

-

Reduced Contact Resistance: Gold plating minimizes contact resistance, which is crucial for applications that require low and stable contact resistance.

-

Compatibility with Wire Bonding: Gold-plated surfaces are compatible with various wire bonding techniques, making them suitable for semiconductor packaging applications.

Applications of PCB Gold Plating

PCB gold plating is commonly used in various industries and applications, including:

- High-frequency and RF devices

- Medical devices and implantable electronics

- Aerospace and military equipment

- Automotive electronics

- Semiconductor packaging and wire bonding

- Connectors and switches

- Test and measurement equipment

Selective Gold Plating Techniques

There are several techniques used for selectively applying gold plating to PCBs. Each method has its advantages and limitations, and the choice of technique depends on the specific requirements of the application.

Electroplating

Electroplating is the most common method for selective gold plating. In this process, the PCB is submerged in a gold plating solution, and an electric current is applied to the desired areas using a patterned photoresist mask. The gold ions in the solution are reduced and deposited onto the exposed surfaces of the PCB.

Advantages:

– Allows for precise control over the plating thickness

– Suitable for high-volume production

– Provides excellent adhesion and uniformity

Limitations:

– Requires a conductive surface for plating

– Involves multiple steps, including photoresist application and removal

Immersion Gold Plating

Immersion gold plating is a chemical process that does not require an external electric current. The PCB is immersed in a gold plating solution, and the gold ions replace the surface atoms of the base metal (usually nickel) through a displacement reaction.

Advantages:

– Simple and cost-effective process

– Does not require a conductive surface

– Provides a thin, uniform gold layer

Limitations:

– Limited control over the plating thickness

– May result in a porous gold layer due to the replacement reaction

Brush Plating

Brush plating, also known as selective plating or spot plating, involves applying the gold plating solution to specific areas of the PCB using a brush or a pen-like tool. An electric current is applied between the brush and the PCB surface to facilitate the deposition of gold.

Advantages:

– Allows for precise control over the plating area

– Suitable for small-scale production and rework

– Can be performed on assembled PCBs

Limitations:

– Time-consuming process for large areas

– Requires skilled operators to ensure uniform plating

Gold Plating Specifications and Standards

Several specifications and standards govern the quality and requirements for PCB gold plating. These standards ensure the consistency, reliability, and performance of gold-plated PCBs.

IPC-4552 Specification for Electroless Nickel/Immersion Gold (ENIG) Plating

IPC-4552 is the most widely used specification for ENIG plating. It defines the requirements for the thickness, composition, and performance of the nickel and gold layers.

| Layer | Thickness Range |

|---|---|

| Gold | 0.05 – 0.15 μm (2 – 6 μin) |

| Nickel | 3 – 6 μm (118 – 236 μin) |

MIL-DTL-45204 Specification for Electrodeposited Coatings of Gold

MIL-DTL-45204 is a military specification that outlines the requirements for electroplated gold coatings on various substrates, including PCBs. It specifies the thickness, purity, and performance characteristics of the gold plating.

| Type | Minimum Purity | Thickness Range |

|---|---|---|

| Type I | 99.7% | 0.25 – 5.0 μm (10 – 200 μin) |

| Type II | 99.0% | 0.25 – 5.0 μm (10 – 200 μin) |

ASTM B488 Standard Specification for Electroplated Coatings of Gold

ASTM B488 is a standard specification that covers the requirements for electroplated gold coatings on various substrates, including PCBs. It specifies the thickness, appearance, and performance characteristics of the gold plating.

| Grade | Minimum Purity | Thickness Range |

|---|---|---|

| Grade A | 99.7% | 0.25 – 5.0 μm (10 – 200 μin) |

| Grade B | 99.0% | 0.25 – 5.0 μm (10 – 200 μin) |

Gold Plating Process Control and Quality Assurance

Proper process control and quality assurance are essential for achieving consistent and reliable gold plating on PCBs. Several factors should be monitored and controlled to ensure the quality of the gold plating.

Plating Solution Control

The gold plating solution must be regularly monitored and maintained to ensure its stability and performance. Key parameters to control include:

- Gold concentration

- pH level

- Temperature

- Contamination levels

Plating Thickness Measurement

Measuring the thickness of the gold plating is crucial for ensuring compliance with specifications and standards. Common methods for measuring gold thickness include:

- X-ray fluorescence (XRF) spectroscopy

- Beta backscatter

- Coulometric analysis

Adhesion and Solderability Testing

Adhesion and solderability tests are performed to assess the quality and reliability of the gold plating. Common test methods include:

- Cross-cut tape test (IPC-TM-650 2.4.1)

- Solder float test (IPC-TM-650 2.6.8)

- Solder dip and look test (IPC-TM-650 2.4.13)

Visual Inspection

Visual inspection is a simple yet effective method for detecting defects and inconsistencies in the gold plating. Inspectors should look for issues such as:

- Discoloration

- Pitting

- Nodules

- Uneven plating

- Missed plating areas

Troubleshooting Common Gold Plating Issues

Despite proper process control and quality assurance measures, issues may still arise during PCB gold plating. Here are some common problems and their possible causes and solutions:

- Dull or Discolored Plating

- Causes: Contaminated plating solution, incorrect solution pH, or low gold concentration

-

Solutions: Analyze and adjust the plating solution, perform regular solution maintenance

-

Pitting or Porosity

- Causes: Inadequate surface preparation, contamination, or excessive plating current density

-

Solutions: Improve surface cleaning and activation, optimize plating parameters

-

Poor Adhesion

- Causes: Insufficient surface preparation, contamination, or incompatible underplating

-

Solutions: Ensure proper surface cleaning and activation, use compatible underplating (e.g., nickel)

-

Uneven Plating Thickness

- Causes: Incorrect current distribution, poor solution agitation, or uneven surface preparation

-

Solutions: Optimize the plating setup, improve solution agitation, ensure uniform surface preparation

-

Overplating or Underplating

- Causes: Incorrect plating time or current density, inaccurate thickness measurement

- Solutions: Calibrate and monitor the plating process, use reliable thickness measurement techniques

FAQ

1. What is the difference between selective gold plating and full gold plating?

Selective gold plating involves applying gold to specific areas of the PCB, while full gold plating covers the entire surface of the PCB. Selective plating is more cost-effective and is used when gold is required only in certain areas, such as contact fingers or wire bonding pads.

2. Can gold plating be applied directly to copper?

While it is possible to apply gold plating directly to copper, it is not recommended. Copper can diffuse into the gold layer, leading to intermixing and degradation of the plating. A nickel underplating is typically used as a barrier layer between the copper and gold to prevent this issue.

3. How does the thickness of the gold plating affect its performance?

The thickness of the gold plating influences its durability, corrosion resistance, and electrical performance. Thicker gold plating provides better protection against wear and corrosion, but it also increases the cost. The optimal thickness depends on the specific application and requirements.

4. What is the shelf life of a gold-plated PCB?

The shelf life of a gold-plated PCB depends on various factors, such as the storage conditions, the thickness of the gold plating, and the presence of a nickel underplating. Under proper storage conditions, a gold-plated PCB can have a shelf life of several years. However, it is recommended to use the PCBs within a shorter timeframe to ensure optimal solderability and performance.

5. Can gold-plated PCBs be reworked or repaired?

Yes, gold-plated PCBs can be reworked or repaired, but it requires careful handling and specialized techniques. The gold plating can be removed using chemical or mechanical methods, and the affected areas can be re-plated or touched up using brush plating. However, it is essential to follow proper procedures to avoid damaging the PCB or compromising its performance.

In conclusion, selective gold plating is a valuable technique for enhancing the performance and reliability of PCBs in various applications. By understanding the different plating methods, specifications, and quality control measures, manufacturers can produce high-quality gold-plated PCBs that meet the stringent requirements of today’s electronics industry. With proper process control and troubleshooting, gold plating can provide a durable and effective solution for improving the electrical and mechanical properties of PCBs.

No responses yet