Introduction to PCB Prototyping

PCB (Printed Circuit Board) prototyping is an essential step in the electronics design process. It allows designers and engineers to test and validate their designs before mass production, saving time and money in the long run. In this article, we will explore the basics of PCB prototyping, its importance, and how you can try PCB Prototype for free.

What is a PCB Prototype?

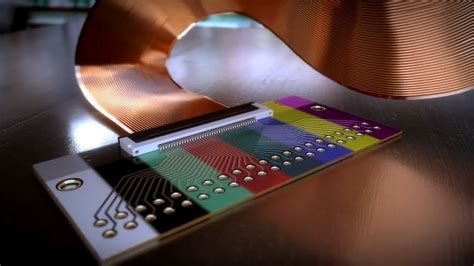

A PCB prototype is a physical representation of a circuit board design. It is created to test the functionality, reliability, and performance of the circuit before mass production. PCB prototypes are typically made in small quantities, ranging from one to a few dozen, depending on the complexity of the design and the testing requirements.

Why is PCB Prototyping Important?

PCB prototyping is crucial for several reasons:

-

Design Validation: Prototyping allows designers to test their designs in real-world conditions, ensuring that the circuit functions as intended.

-

Error Detection: By creating a prototype, designers can identify and fix any errors or issues in the design before mass production, saving time and money.

-

Performance Optimization: Prototyping enables designers to optimize the circuit’s performance by fine-tuning components and layouts.

-

Cost Reduction: Identifying and fixing issues during the prototyping phase helps avoid costly mistakes during mass production.

PCB Prototype Manufacturing Process

The PCB prototype manufacturing process typically involves the following steps:

1. Design Creation

The first step in PCB prototyping is creating the circuit design using specialized software such as Altium Designer, Eagle, or KiCad. The designer creates a schematic diagram and a PCB layout, specifying the components, their placement, and the connections between them.

2. Design Review and Verification

Once the design is complete, it undergoes a thorough review and verification process. This step ensures that the design meets all the necessary specifications, such as component compatibility, signal integrity, and manufacturability.

3. Gerber File Generation

After the design is verified, the designer generates Gerber files, which are industry-standard files that contain all the necessary information for PCB fabrication. Gerber files include data on the copper layers, solder mask, silkscreen, and drill holes.

4. PCB Fabrication

The Gerber files are then sent to a PCB manufacturer, who fabricates the PCB prototype using various processes such as:

- Etching: The copper layers are selectively removed to create the desired circuit pattern.

- Drilling: Holes are drilled through the PCB to accommodate components and vias.

- Plating: The holes are plated with copper to establish electrical connections between layers.

- Solder Mask Application: A protective layer is applied to the PCB to insulate the copper traces and prevent short circuits.

- Silkscreen Printing: Text and symbols are printed on the PCB for component identification and assembly instructions.

5. Component Sourcing and Assembly

Once the PCB is fabricated, the required components are sourced and assembled onto the board. This step can be done manually or using automated assembly machines, depending on the complexity of the design and the quantity of prototypes required.

6. Testing and Validation

The assembled PCB prototype undergoes rigorous testing and validation to ensure that it functions as intended. This step may involve functional testing, environmental testing, and compliance testing, depending on the application and industry standards.

Benefits of Free PCB Prototyping Services

Many PCB manufacturers offer free PCB prototyping services to help designers and engineers test their designs without incurring significant costs. These services typically include:

-

Free PCB Fabrication: Manufacturers offer a limited number of free PCB prototypes, usually up to a certain size and complexity.

-

Quick Turnaround: Free PCB prototyping services often prioritize quick turnaround times, allowing designers to receive their prototypes within a few days.

-

Design Support: Some manufacturers provide design support and feedback to help designers optimize their designs for manufacturability and reliability.

-

No Minimum Order Quantity: Free PCB prototyping services usually have no minimum order quantity, making it easy for designers to test their designs without committing to large production runs.

How to Choose a Free PCB Prototyping Service

When selecting a free PCB prototyping service, consider the following factors:

-

Manufacturing Capabilities: Ensure that the manufacturer has the necessary capabilities to fabricate your PCB prototype, including the required layer count, material, and surface finish.

-

Design Restrictions: Check the manufacturer’s design restrictions for free PCB prototypes, such as maximum size, minimum feature size, and drill hole size.

-

Turnaround Time: Consider the manufacturer’s turnaround time for free PCB prototypes, especially if you have tight deadlines.

-

Customer Support: Look for a manufacturer that offers reliable customer support and design assistance to help you through the prototyping process.

Popular Free PCB Prototyping Services

Some popular free PCB prototyping services include:

-

PCBWay: Offers up to 10 pieces of 2-layer PCBs for free, with a maximum size of 100x100mm and a lead time of 24 hours.

-

JLCPCB: Provides up to 10 pieces of 2-layer PCBs for $2, with a maximum size of 100x100mm and a lead time of 24 hours.

-

ALLPCB: Offers up to 5 pieces of 2-layer PCBs for free, with a maximum size of 50x50mm and a lead time of 24-48 hours.

-

OSH Park: Provides up to 3 copies of 2-layer PCBs for $5 per square inch, with no maximum size limit and a lead time of 12-15 days.

| Service | Free Offer | Max Size | Lead Time |

|---|---|---|---|

| PCBWay | 10 pcs 2-layer PCBs | 100x100mm | 24 hours |

| JLCPCB | 10 pcs 2-layer PCBs for $2 | 100x100mm | 24 hours |

| ALLPCB | 5 pcs 2-layer PCBs | 50x50mm | 24-48 hours |

| OSH Park | 3 copies 2-layer PCBs for $5/in² | No limit | 12-15 days |

Frequently Asked Questions (FAQ)

1. What is the typical turnaround time for free PCB prototypes?

The typical turnaround time for free PCB prototypes ranges from 24 hours to 15 days, depending on the manufacturer and the complexity of the design.

2. Are there any limitations on the design complexity for free PCB prototypes?

Yes, most free PCB prototyping services have limitations on the design complexity, such as the maximum number of layers, minimum feature size, and drill hole size. Be sure to check the manufacturer’s design restrictions before submitting your design.

3. Can I get free assembled PCB prototypes?

While some manufacturers offer free PCB fabrication, free assembled PCB prototypes are less common. However, some services may provide low-cost assembly options for prototypes.

4. How many free PCB prototypes can I get?

The number of free PCB prototypes varies by manufacturer, but typically ranges from 5 to 10 pieces for 2-layer designs.

5. What happens if I need more than the offered number of free PCB prototypes?

If you require more than the offered number of free PCB prototypes, you will need to pay for the additional pieces. Most manufacturers offer competitive pricing for low-volume production runs.

Conclusion

PCB prototyping is a critical step in the electronics design process, allowing designers and engineers to test and validate their designs before mass production. By taking advantage of free PCB prototyping services, you can save time and money while ensuring that your design is reliable and performs as intended.

When choosing a free PCB prototyping service, consider factors such as manufacturing capabilities, design restrictions, turnaround time, and customer support. By carefully selecting a reputable manufacturer, you can streamline your prototyping process and bring your products to market faster.

No responses yet