Introduction to Silk Screen PCB

Silk screen technology, also known as screen printing, is a versatile and widely used method for applying various types of designs and markings onto printed circuit boards (PCBs). In the PCB industry, silk screen printing is employed to create informative and aesthetic features on the surface of the boards, enhancing their functionality and visual appeal. This article delves into the intricacies of silk screen PCB technology, its applications, advantages, and the process involved in creating high-quality screen-printed circuit boards.

What is Silk Screen Printing?

Silk screen printing is a stencil-based printing technique that involves forcing ink or other printable materials through a fine mesh screen onto a substrate, such as a PCB. The screen is partially blocked off with a stencil, which defines the desired design or pattern to be printed. The open areas of the screen allow the ink to pass through, creating a precise and uniform print on the surface of the substrate.

History of Silk Screen Printing

The origins of silk screen printing can be traced back to ancient China, where silk mesh was used as a stencil material for applying patterns onto fabrics. Over time, the technique evolved and found applications in various industries, including textiles, graphic design, and eventually, electronics. In the PCB industry, silk screen printing has become an integral part of the manufacturing process, enabling the creation of informative and visually appealing circuit boards.

Applications of Silk Screen PCB

Silk screen printing on PCBs serves several essential purposes, contributing to the overall functionality, aesthetics, and usability of the boards. Some of the key applications of silk screen PCB include:

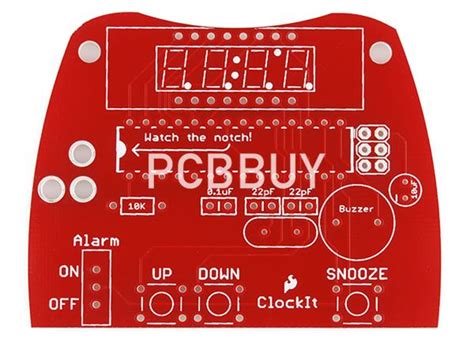

Component Identification

One of the primary uses of silk screen printing on PCBs is to provide clear and legible component identification markings. These markings typically include component designators, such as “R1” for a resistor or “C2” for a capacitor, which help in the assembly, debugging, and maintenance of the circuit board. Silk screen printing ensures that the component identifiers are easily readable and durable, even after prolonged use.

Orientation Indicators

Silk screen printing is also used to apply orientation indicators on PCBs, such as polarity markings for capacitors and diodes, or pin numbering for integrated circuits (ICs). These indicators help ensure correct component placement during assembly, reducing the risk of errors and potential damage to the board or components.

Branding and Aesthetics

In addition to functional markings, silk screen printing allows for the application of aesthetic elements on PCBs, such as company logos, product names, or decorative patterns. These visual features contribute to the overall branding and professional appearance of the end product, making it more attractive to potential customers.

Instructional Information

Silk screen printing can be used to apply instructional information or warnings on PCBs, such as handling precautions, operating instructions, or safety guidelines. This information helps users interact with the board correctly and safely, minimizing the risk of accidents or misuse.

Advantages of Silk Screen PCB

Silk screen printing offers several advantages over other marking methods for PCBs, making it a preferred choice in the industry. Some of the key benefits of silk screen PCB include:

Durability

Silk screen printing produces durable and long-lasting markings on PCBs. The ink used in the process is formulated to withstand harsh environmental conditions, such as high temperatures, humidity, and exposure to chemicals. This durability ensures that the markings remain legible and intact throughout the lifespan of the circuit board.

High Resolution and Precision

Silk screen printing allows for the creation of high-resolution and precise markings on PCBs. The fine mesh screens used in the process enable the reproduction of intricate designs and small text with exceptional clarity and sharpness. This level of precision is crucial for ensuring the readability of component identifiers and other critical information on the board.

Cost-Effectiveness

Compared to other marking methods, such as direct inkjet printing or laser marking, silk screen printing is a cost-effective solution for applying designs and markings on PCBs. The process is particularly economical for large production runs, as the initial setup costs are relatively low, and the printing process itself is efficient and fast.

Versatility

Silk screen printing is a versatile technique that can be used on a wide range of PCB materials, including FR-4, aluminum, and flexible substrates. It is also compatible with various ink types, including conductive, resistive, and dielectric inks, allowing for the creation of functional elements on the board, such as resistors or capacitive touch sensors.

The Silk Screen PCB Process

The silk screen PCB process involves several steps, from design preparation to the actual printing of the circuit board. Here’s a detailed overview of the process:

Step 1: Design Preparation

The first step in the silk screen PCB process is to prepare the design files for the desired markings and patterns. This typically involves creating a vector-based artwork using computer-aided design (CAD) software, such as Adobe Illustrator or CorelDRAW. The artwork should be carefully reviewed and optimized for screen printing, ensuring that the line widths, text sizes, and overall layout are suitable for the chosen mesh size and ink type.

Step 2: Screen Preparation

Once the design is finalized, a stencil is created based on the artwork. The stencil is typically made by coating a fine mesh screen with a light-sensitive emulsion and exposing it to light through a film positive of the artwork. The exposed areas of the emulsion harden, while the unexposed areas remain soluble and can be washed away, leaving a precise stencil of the design on the screen.

Step 3: Ink Preparation

The ink used for silk screen printing on PCBs is specially formulated to adhere to the board material and provide the desired properties, such as color, durability, and electrical characteristics (if applicable). The ink is carefully mixed and adjusted for viscosity and consistency to ensure optimal printing results.

Step 4: Printing Process

With the screen and ink prepared, the actual printing process can begin. The PCB is placed on the printing bed, and the screen is positioned above it. Ink is then applied to the screen and spread evenly using a squeegee. As the squeegee moves across the screen, it forces the ink through the open areas of the stencil, transferring the design onto the surface of the PCB. This process is repeated for each individual board in the production run.

Step 5: Curing and Finishing

After printing, the ink needs to be cured to ensure proper adhesion and durability. The curing process typically involves exposing the printed PCBs to heat, either through an oven or infrared lamps. The temperature and duration of the curing process depend on the specific ink formulation used. Once cured, the PCBs undergo a final inspection to ensure the quality and accuracy of the printed markings before proceeding to the next stages of the manufacturing process.

Factors Affecting Silk Screen PCB Quality

Several factors can impact the quality of silk screen printing on PCBs. To achieve the best results, it is essential to consider and control these factors throughout the process:

Mesh Count and Thread Diameter

The mesh count and thread diameter of the screen used for printing play a crucial role in determining the resolution and ink deposit thickness of the printed design. Higher mesh counts (e.g., 400 threads per inch) produce finer details and thinner ink deposits, while lower mesh counts (e.g., 200 threads per inch) result in thicker ink deposits and slightly less detail. Choosing the appropriate mesh count depends on the specific requirements of the design and the desired end result.

Emulsion Thickness

The thickness of the emulsion coating on the screen also affects the quality of the printed design. A thicker emulsion layer results in a higher ink deposit and can be useful for creating bold, opaque markings. However, excessively thick emulsion layers can lead to poor detail resolution and may cause issues with ink flow and drying time.

Ink Formulation and Viscosity

The formulation and viscosity of the ink used for silk screen printing on PCBs must be carefully controlled to ensure optimal printing results. The ink should have the appropriate flow characteristics, allowing it to pass through the screen mesh easily and form a smooth, even layer on the PCB surface. Additionally, the ink must have good adhesion properties and be compatible with the chosen curing method to ensure long-lasting and durable markings.

Squeegee Pressure and Angle

The pressure and angle at which the squeegee is applied during the printing process can significantly impact the quality of the printed design. Insufficient pressure may result in incomplete ink transfer and uneven coverage, while excessive pressure can cause ink bleeding or smudging. Similarly, the squeegee angle affects the ink deposit thickness and the sharpness of the printed edges. Finding the optimal pressure and angle settings requires careful experimentation and adjustment based on the specific screen, ink, and PCB characteristics.

Curing Conditions

Proper curing of the printed ink is essential for achieving durable and long-lasting markings on PCBs. The curing temperature, duration, and method (e.g., oven or infrared) must be carefully controlled to ensure complete ink polymerization and adhesion to the PCB surface. Insufficient curing can lead to poor durability and resistance to abrasion or chemical exposure, while excessive curing may cause discoloration or damage to the PCB substrate.

Common Challenges and Solutions in Silk Screen PCB

Despite the many advantages of silk screen printing for PCBs, there are some common challenges that manufacturers may face during the process. Here are a few of these challenges and potential solutions:

Challenge 1: Ink Bleeding or Smudging

Ink bleeding or smudging can occur when the ink spreads beyond the intended design boundaries, resulting in a blurred or distorted appearance. This issue is often caused by excessive ink deposit, improper screen tension, or incompatible ink formulation.

Solution: To minimize ink bleeding or smudging, ensure that the screen mesh count and emulsion thickness are appropriate for the design requirements. Adjust the squeegee pressure and angle to control the ink deposit, and use an ink formulation with the proper viscosity and flow characteristics for the chosen screen and PCB material.

Challenge 2: Poor Ink Adhesion

Poor ink adhesion can result in the printed markings easily rubbing off or peeling away from the PCB surface, compromising the durability and legibility of the design.

Solution: To improve ink adhesion, ensure that the PCB surface is clean and free from contaminants before printing. Use an ink formulation that is compatible with the PCB material and has good adhesion properties. Additionally, ensure that the curing process is carried out correctly, with the appropriate temperature and duration settings for the specific ink type.

Challenge 3: Inconsistent Ink Coverage

Inconsistent ink coverage can occur when the printed design exhibits variation in opacity or thickness across different areas of the PCB, resulting in an uneven or patchy appearance.

Solution: To achieve consistent ink coverage, maintain proper screen tension and ensure that the squeegee pressure and angle are uniform throughout the printing process. Use an ink formulation with the appropriate viscosity and flow characteristics, and consider adjusting the mesh count or emulsion thickness to optimize ink deposit uniformity.

Challenge 4: Registration Errors

Registration errors occur when the printed design is misaligned or not accurately positioned on the PCB, which can lead to issues with component placement and overall functionality.

Solution: To minimize registration errors, ensure that the screen and PCB are properly aligned before printing. Use registration marks or fiducials to help guide the alignment process, and consider investing in automated screen printing equipment with advanced registration control features for high-precision applications.

FAQ

1. What is the difference between silk screen PCB and other marking methods?

Silk screen PCB differs from other marking methods, such as direct inkjet printing or laser marking, in several ways. Silk screen printing uses a stencil-based approach, forcing ink through a fine mesh screen onto the PCB surface, while inkjet printing directly deposits ink droplets onto the board. Laser marking, on the other hand, uses a focused laser beam to etch or discolor the PCB surface. Silk screen printing offers advantages in terms of durability, precision, and cost-effectiveness, particularly for large production runs.

2. Can silk screen printing be used for creating conductive traces on PCBs?

Yes, silk screen printing can be used to create conductive traces on PCBs using specialized conductive inks. These inks typically contain metal particles, such as silver or copper, which form a conductive pathway when printed and cured onto the PCB surface. However, for high-precision or high-density conductive patterns, other methods, such as photolithography or direct impression, may be more suitable.

3. What is the maximum resolution achievable with silk screen PCB?

The maximum resolution achievable with silk screen PCB depends on several factors, including the mesh count of the screen, the emulsion thickness, and the ink formulation. In general, higher mesh counts (e.g., 400 threads per inch) and thinner emulsion layers enable finer detail resolution. With optimal settings, silk screen printing can typically achieve line widths and spacing down to about 0.1 mm (4 mil) for most PCB Applications.

4. How durable are silk screen printed markings on PCBs?

Silk screen printed markings on PCBs are generally very durable, as the inks used are formulated to withstand harsh environmental conditions and prolonged use. When properly cured, the printed markings exhibit excellent adhesion to the PCB surface and resistance to abrasion, chemicals, and extreme temperatures. The durability of the markings can be further enhanced by using specialized ink formulations or applying protective coatings over the printed areas.

5. Can silk screen PCB be used for both prototyping and mass production?

Yes, silk screen PCB is suitable for both prototyping and mass production. For prototyping or low-volume production, manual screen printing setups can be used to quickly and cost-effectively apply markings or designs onto PCBs. For mass production, automated screen printing equipment offers high throughput and consistent quality, making it an ideal choice for large-scale PCB manufacturing. The versatility of silk screen printing allows it to be adapted to various production scales and requirements.

Conclusion

Silk screen technology plays a vital role in the production of high-quality and functional printed circuit boards. By enabling the precise and durable application of informative markings, aesthetic elements, and even functional components, silk screen PCB enhances the overall value and usability of electronic devices. As the electronics industry continues to evolve, silk screen printing remains an essential tool for PCB manufacturers, offering a reliable and cost-effective solution for creating visually appealing and informative circuit boards.

Through a thorough understanding of the silk screen PCB process, its advantages, and the factors affecting print quality, manufacturers can optimize their production workflows and overcome common challenges. By staying up-to-date with the latest developments in screen printing technology and ink formulations, PCB manufacturers can continue to deliver innovative and high-performance products that meet the ever-increasing demands of the electronics market.

In conclusion, silk screen PCB technology is an indispensable aspect of modern printed circuit board production, offering a versatile and dependable method for applying critical markings and designs. As the industry progresses, it is clear that silk screen printing will continue to play a significant role in shaping the future of PCB manufacturing, enabling the creation of increasingly sophisticated and visually striking electronic devices.

No responses yet