Introduction to IC-PCBs

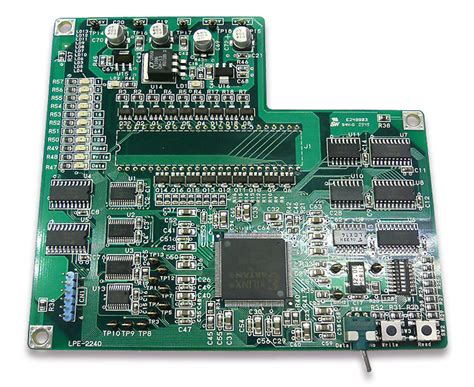

In the world of electronics, printed circuit boards (PCBs) play a crucial role in connecting and supporting various components. Among the most advanced and specialized types of PCBs are IC substrates and IC probe cards. These high-performance PCBs are designed to meet the demanding requirements of integrated circuits (ICs) and provide reliable interconnections for testing and packaging purposes.

What are IC Substrates?

IC substrates, also known as chip carriers or packaging substrates, are specialized PCBs that serve as the foundation for mounting and interconnecting semiconductor dies or chips. They provide a stable and efficient platform for integrating ICs into electronic devices. IC substrates are typically made of advanced materials such as bismaleimide triazine (BT) resin, polyimide, or ceramic, which offer excellent electrical, thermal, and mechanical properties.

What are IC Probe Cards?

IC probe cards are another type of advanced PCB used in the semiconductor industry for testing and characterizing ICs during the manufacturing process. These PCBs are designed to establish a temporary electrical connection between the IC and the testing equipment. Probe cards feature an array of fine-pitched probes or pins that make contact with the IC’s bond pads or bumps, allowing for precise measurements and analysis of the chip’s functionality and performance.

Key Features and Benefits of IC-PCBs

High-Density Interconnects (HDI)

One of the distinguishing features of IC substrates and probe cards is their ability to accommodate high-density interconnects (HDI). HDI technology enables the creation of fine-pitch traces, micro-vias, and blind/buried vias, allowing for the interconnection of a large number of signals in a compact space. This is essential for modern ICs that have a high pin count and require efficient routing of signals between the chip and the PCB.

Advanced Materials and Manufacturing Processes

IC-PCBs employ advanced materials and manufacturing processes to achieve superior performance and reliability. Some common materials used in IC substrates include:

| Material | Properties |

|---|---|

| BT Resin | High glass transition temperature, low moisture absorption, good dimensional stability |

| Polyimide | Excellent thermal stability, high flexibility, good electrical insulation |

| Ceramic | High thermal conductivity, low coefficient of thermal expansion (CTE), good dielectric properties |

These materials are chosen based on their ability to withstand the harsh operating conditions and meet the specific requirements of the IC packaging process.

Precise Impedance Control

Maintaining precise impedance control is crucial for high-speed and high-frequency applications. IC substrates and probe cards are designed with controlled impedance traces and planes to ensure signal integrity and minimize signal distortion. By carefully selecting the dielectric materials and controlling the trace widths and spacings, IC-PCBs can achieve the desired impedance values and minimize signal reflections and crosstalk.

Thermal Management

Thermal management is a critical aspect of IC-PCBs, as ICs generate significant amounts of heat during operation. IC substrates often incorporate thermal vias and heat spreaders to efficiently dissipate heat away from the chip and prevent thermal-related failures. Probe cards, on the other hand, need to maintain a stable temperature during testing to ensure accurate measurements. They may include temperature sensors and cooling mechanisms to regulate the temperature and minimize thermal drift.

Applications of IC-PCBs

IC Packaging

IC substrates are extensively used in the packaging of semiconductor devices. They provide a reliable and efficient means of interconnecting the IC die to the external circuitry. Various packaging technologies, such as flip-chip, ball grid array (BGA), and chip-scale packaging (CSP), rely on IC substrates to achieve high-density interconnects and improved electrical performance.

Semiconductor Testing

IC probe cards are indispensable tools in the semiconductor testing process. They enable the electrical characterization and functional testing of ICs at the wafer level before the chips are packaged. Probe cards are designed to match the specific layout and pin configuration of the IC under test, ensuring accurate and reliable measurements. They are used in a wide range of testing applications, including:

- Wafer sort testing

- Burn-in testing

- Reliability testing

- Failure analysis

Advanced Packaging Technologies

IC-PCBs play a vital role in advanced packaging technologies that aim to improve performance, reduce form factors, and enable heterogeneous integration. Some notable examples include:

-

2.5D Packaging: IC substrates are used as interposers to interconnect multiple dies in a side-by-side configuration. This allows for higher bandwidth and shorter interconnects between the dies compared to traditional packaging methods.

-

3D Packaging: IC substrates are stacked vertically to create 3D packages, enabling higher density and improved performance. Through-silicon vias (TSVs) are used to establish vertical interconnects between the stacked dies.

-

System-in-Package (SiP): IC substrates serve as the foundation for integrating multiple dies and components into a single package. SiP technology allows for the integration of diverse functionalities, such as digital, analog, and RF, into a compact and highly integrated module.

Challenges and Future Trends

Miniaturization and High-Density Integration

As ICs continue to shrink in size and increase in complexity, IC-PCBs face the challenge of accommodating higher densities and finer pitches. Advancements in HDI technologies, such as ultra-fine pitch traces and micro-vias, are essential to keep pace with the increasing demands of IC packaging and testing.

Signal Integrity and Power Integrity

With the ever-increasing operating frequencies and data rates, maintaining signal integrity and power integrity becomes more challenging in IC-PCBs. Designers need to carefully consider factors such as impedance matching, crosstalk, and power distribution to ensure reliable and error-free operation. Advanced simulation and modeling techniques are employed to optimize the PCB layout and mitigate signal integrity issues.

Cost and Manufacturability

The production of IC substrates and probe cards involves complex and precise manufacturing processes, which can be costly and time-consuming. Balancing the performance requirements with cost-effective manufacturing is a constant challenge. Innovations in materials, processes, and automation are necessary to improve the affordability and scalability of IC-PCB production.

Heterogeneous Integration

The trend towards heterogeneous integration, where different types of devices and technologies are integrated into a single package, presents new opportunities and challenges for IC-PCBs. Substrates need to accommodate diverse materials, interconnect technologies, and thermal requirements to enable the integration of various die types, such as logic, memory, and RF. Collaborative efforts between IC designers, packaging experts, and PCB manufacturers are crucial to address these challenges and drive innovation in heterogeneous integration.

Frequently Asked Questions (FAQ)

-

What is the difference between IC substrates and traditional PCBs?

IC substrates are specialized PCBs designed specifically for packaging and interconnecting semiconductor dies or chips. They are made of advanced materials and feature high-density interconnects to accommodate the fine-pitch and high-pin-count requirements of ICs. Traditional PCBs, on the other hand, are used for general-purpose electronic circuits and may not have the same level of interconnect density or material properties as IC substrates. -

How do IC probe cards differ from IC substrates?

IC probe cards are used for testing and characterizing ICs at the wafer level, while IC substrates are used for packaging and interconnecting ICs. Probe cards have an array of fine-pitched probes or pins that make temporary contact with the IC’s bond pads or bumps for testing purposes. IC substrates, on the other hand, provide a permanent interconnection between the IC die and the external circuitry in the final packaged device. -

What are the key considerations for designing IC-PCBs?

When designing IC-PCBs, several key factors need to be considered, including: - High-density interconnects and fine-pitch routing

- Signal integrity and impedance control

- Thermal management and heat dissipation

- Materials selection based on electrical, thermal, and mechanical properties

-

Manufacturing feasibility and cost-effectiveness

-

What role do IC-PCBs play in advanced packaging technologies?

IC-PCBs are fundamental to advanced packaging technologies such as 2.5D packaging, 3D packaging, and system-in-package (SiP). They serve as interposers, substrates, or carriers for interconnecting multiple dies and components in a compact and highly integrated package. IC-PCBs enable higher bandwidth, shorter interconnects, and heterogeneous integration, which are essential for achieving improved performance and functionality in advanced packaging solutions. -

How are IC-PCBs evolving to meet future demands?

IC-PCBs are continuously evolving to keep pace with the advancing semiconductor industry. Some key trends and developments include: - Miniaturization and increased interconnect density

- Adoption of advanced materials with improved electrical and thermal properties

- Integration of passive components and active devices within the substrate

- Development of novel packaging technologies, such as fan-out wafer-level packaging (FOWLP) and chiplets

- Emphasis on cost reduction and manufacturing efficiency through process innovations and automation

Conclusion

IC substrates and IC probe cards represent the cutting-edge of PCB technology, enabling the packaging, testing, and integration of advanced semiconductor devices. These specialized PCBs play a critical role in meeting the demanding requirements of high-density interconnects, signal integrity, and thermal management in modern electronic systems.

As the semiconductor industry continues to push the boundaries of miniaturization and performance, IC-PCBs will remain at the forefront of innovation. Advancements in materials, manufacturing processes, and design techniques will be crucial to address the challenges of increasing complexity, heterogeneous integration, and cost-effectiveness.

The development of IC-PCBs requires close collaboration between IC designers, packaging experts, PCB manufacturers, and testing specialists. By leveraging the expertise and innovation across these domains, the industry can continue to deliver cutting-edge solutions that enable the next generation of electronic devices and systems.

In conclusion, IC substrates and IC probe cards are the unsung heroes of the semiconductor world, providing the foundation for the seamless integration and reliable operation of advanced ICs. As technology progresses, these specialized PCBs will continue to evolve and play a vital role in shaping the future of electronics.

No responses yet