Understanding the Basics of PCB Design

Before diving into specific guidelines, it’s crucial to understand the fundamentals of PCB design. A printed circuit board is a flat board made of insulating material, such as fiberglass or plastic, with conductive copper traces etched onto its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits, to form a complete electronic circuit.

PCB design involves several key aspects, including:

- Schematic design

- Component placement

- Routing

- Manufacturing considerations

Schematic Design

Schematic design is the first step in creating a PCB. It involves drawing a diagram that represents the electrical connections between components. A well-designed schematic is essential for a successful PCB design. Some tips for creating a good schematic include:

- Use consistent naming conventions for components and nets

- Keep the schematic organized and easy to read

- Use appropriate symbols for components

- Include necessary information, such as component values and package types

Component Placement

Once the schematic is complete, the next step is to place the components on the PCB. Proper component placement is crucial for several reasons:

- It affects the routing of traces

- It impacts the overall size and shape of the PCB

- It can affect the performance and reliability of the circuit

When placing components, consider the following guidelines:

- Group related components together

- Place components in a logical flow, following the signal path

- Consider the mechanical constraints of the PCB, such as mounting holes and connectors

- Leave enough space between components for routing traces

Routing

Routing is the process of creating the conductive traces that connect the components on the PCB. Proper routing is essential for several reasons:

- It ensures that signals can travel between components without interference

- It minimizes the risk of signal integrity issues, such as crosstalk and reflections

- It can affect the manufacturing cost and reliability of the PCB

When routing traces, keep the following guidelines in mind:

- Use appropriate trace widths and spacings for the signal type and frequency

- Avoid sharp angles and unnecessary bends in traces

- Keep traces as short as possible to minimize signal delay and attenuation

- Use ground planes and power planes to provide a low-impedance return path for signals

- Follow the manufacturer’s guidelines for minimum trace widths and spacings

Manufacturing Considerations

Finally, it’s essential to consider the manufacturing process when designing a PCB. Some key factors to keep in mind include:

- The number of layers in the PCB

- The minimum feature size (trace width and spacing) that can be manufactured reliably

- The type of vias (through-hole or blind/buried) used in the design

- The surface finish (HASL, ENIG, OSP) required for the application

- The soldermask and silkscreen requirements

By considering these factors early in the design process, you can avoid costly redesigns and manufacturing issues later on.

Key PCB Design Guidelines

Now that we’ve covered the basics of PCB design let’s dive into some specific guidelines that will help you create reliable, efficient, and cost-effective PCBs.

1. Choose the Right PCB Material

The choice of PCB material depends on several factors, including:

- The operating temperature range of the circuit

- The frequency and power requirements of the signals

- The environmental conditions (humidity, vibration, etc.) the PCB will be exposed to

- The cost and availability of the material

Some common PCB Materials include:

- FR-4: A standard fiberglass-reinforced epoxy laminate material suitable for most applications

- High-Tg FR-4: A variant of FR-4 with better Thermal stability and lower moisture absorption

- Rogers: A family of high-performance materials designed for high-frequency and high-speed applications

- Polyimide: A flexible material suitable for applications that require bending or flexing of the PCB

When choosing a PCB material, consult with your manufacturer to ensure that it meets your specific requirements and is compatible with their manufacturing process.

2. Use Appropriate Trace Widths and Spacings

The width and spacing of traces on a PCB have a significant impact on the signal integrity and manufacturing reliability of the board. In general, wider traces have lower resistance and can carry more current, while narrower traces have higher resistance and are more susceptible to manufacturing defects.

The minimum trace width and spacing that can be manufactured reliably depend on several factors, including:

- The PCB material and thickness

- The copper weight (thickness) of the traces

- The manufacturing process and equipment used by the PCB fabricator

As a general guideline, use the following trace widths for different signal types:

| Signal Type | Trace Width (mm) |

|---|---|

| Power | 0.25 – 0.5 |

| Ground | 0.25 – 0.5 |

| Signal | 0.15 – 0.25 |

| High-speed | 0.1 – 0.15 |

For trace spacings, follow the manufacturer’s guidelines based on the PCB material, copper weight, and manufacturing process. In general, a minimum spacing of 0.15 mm between traces is recommended for most applications.

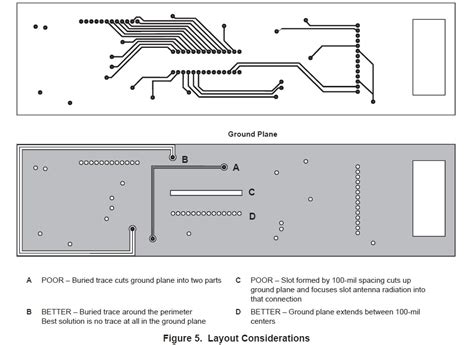

3. Use Ground Planes and Power Planes

Ground planes and power planes are large areas of copper on a PCB Layer that provide a low-impedance return path for signals. They also help to reduce electromagnetic interference (EMI) and improve the overall signal integrity of the board.

When designing a PCB, consider the following guidelines for using ground and power planes:

- Use a solid ground plane on one or more layers of the PCB, connected to the ground pins of components and connectors

- Use separate power planes for different voltage levels, such as 3.3V and 5V

- Use appropriate via stitching to connect ground and power planes between layers

- Keep the ground and power planes as close to the signal layers as possible to minimize loop areas and reduce EMI

4. Follow Good Signal Routing Practices

Proper signal routing is essential for maintaining signal integrity and minimizing crosstalk and reflections. Some key guidelines to follow when routing signals on a PCB include:

- Route signals on appropriate layers based on their frequency and sensitivity

- Keep signal traces as short and direct as possible to minimize delay and attenuation

- Avoid routing signals parallel to each other for long distances to minimize crosstalk

- Use appropriate termination techniques, such as series or parallel termination, for high-speed signals

- Follow the manufacturer’s guidelines for trace impedance and matching

5. Use Appropriate Decoupling Capacitors

Decoupling capacitors are used to reduce noise and ripple on power supply lines and to provide a local source of charge for fast-switching digital circuits. When using decoupling capacitors, follow these guidelines:

- Place decoupling capacitors as close as possible to the power pins of ICs and other components

- Use a combination of bulk and ceramic capacitors to provide both low and high-frequency decoupling

- Use appropriate values and voltage ratings for the capacitors based on the circuit requirements

- Use multiple capacitors in parallel to reduce the effective series resistance (ESR) and inductance (ESL)

6. Consider Thermal Management

Thermal management is essential for ensuring the reliability and longevity of a PCB and its components. Some key considerations for thermal management in PCB design include:

- Use appropriate copper weights and trace widths for high-current paths to minimize resistive heating

- Provide adequate spacing between components to allow for heat dissipation

- Use thermal vias to conduct heat away from components and into the PCB substrate or heatsinks

- Consider the use of thermal interface materials (TIMs) between components and heatsinks

- Follow the manufacturer’s guidelines for maximum junction temperatures and power dissipation of components

7. Plan for Manufacturing and Assembly

Finally, it’s essential to plan for the manufacturing and assembly of the PCB early in the design process. Some key considerations include:

- Choose components with package types that are compatible with the intended manufacturing process (e.g., surface-mount or through-hole)

- Provide adequate clearances and access for automated assembly equipment

- Use appropriate solder mask and silkscreen designs to aid in assembly and inspection

- Follow the manufacturer’s guidelines for minimum hole sizes, pad sizes, and clearances

- Consider the use of panelization to reduce manufacturing costs and improve yields

By following these guidelines and planning for manufacturing and assembly early in the design process, you can avoid costly redesigns and delays later on.

Frequently Asked Questions (FAQ)

- What is the difference between a schematic and a PCB layout?

-

A schematic is a diagram that shows the electrical connections between components, while a PCB layout shows the physical placement and routing of components and traces on the PCB.

-

What is the purpose of a ground plane in PCB design?

-

A ground plane is a large area of copper on a PCB layer that provides a low-impedance return path for signals. It helps to reduce electromagnetic interference (EMI) and improve the overall signal integrity of the board.

-

How do I choose the right trace width for a given signal?

-

The choice of trace width depends on several factors, including the current carrying requirements, the PCB material and thickness, and the manufacturing capabilities of the PCB fabricator. As a general guideline, use wider traces for power and ground signals, and narrower traces for high-speed signals.

-

What is the purpose of decoupling capacitors in PCB design?

-

Decoupling capacitors are used to reduce noise and ripple on power supply lines and to provide a local source of charge for fast-switching digital circuits. They help to ensure stable power delivery to components and improve overall signal integrity.

-

What are some common thermal management techniques used in PCB design?

- Common thermal management techniques in PCB design include using appropriate copper weights and trace widths for high-current paths, providing adequate spacing between components for heat dissipation, using thermal vias to conduct heat away from components, and using thermal interface materials (TIMs) between components and heatsinks.

Conclusion

Designing a reliable, efficient, and cost-effective PCB requires a combination of technical knowledge, practical experience, and attention to detail. By following the guidelines outlined in this article, you can avoid common pitfalls and ensure that your PCB meets the requirements of your application.

Remember to start with a well-designed schematic, choose appropriate components and materials, follow good signal routing practices, and plan for manufacturing and assembly early in the design process. By doing so, you can create PCBs that are not only functional but also reliable and cost-effective.

No responses yet