Introduction to SMT Ordering

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, faster, and more cost-effective electronic devices. The SMT ordering process is a critical step in ensuring the smooth and efficient manufacturing of these devices. This article will provide a comprehensive overview of the necessary files and information required for accurate SMT ordering, which supports efficient quote generation and manufacturing processes.

Key Components of SMT Ordering

To ensure a successful SMT ordering process, several key components must be considered:

Bill of Materials (BOM)

The Bill of Materials (BOM) is a comprehensive list of all the components required to manufacture a particular electronic device. It includes detailed information about each component, such as:

- Part number

- Description

- Quantity

- Manufacturer

- Reference designator

A well-structured and accurate BOM is essential for accurate quoting and efficient manufacturing processes. It helps to ensure that all necessary components are ordered in the correct quantities and specifications.

Gerber Files

Gerber files are industry-standard files used to describe the printed circuit board (PCB) design. They contain information about the copper layers, solder mask, silk screen, and drill holes of the PCB. The following Gerber files are typically required for SMT ordering:

- Top and bottom copper layers (.gtl and .gbl)

- Top and bottom solder mask layers (.gts and .gbs)

- Top and bottom silk screen layers (.gto and .gbo)

- Drill files (.drl)

Accurate Gerber files are crucial for ensuring that the PCB is manufactured according to the desired specifications.

Assembly Drawing

The assembly drawing provides a visual representation of the PCB Assembly, including the placement of components and any special instructions for the assembly process. It typically includes:

- Component locations and orientations

- Special assembly instructions

- Fiducial marks for machine vision alignment

A clear and detailed assembly drawing helps to minimize errors during the SMT assembly process and ensures that the final product meets the required specifications.

Centroid File

The centroid file, also known as the pick-and-place file, contains information about the placement of components on the PCB. It includes:

- Component locations (X and Y coordinates)

- Rotation angles

- Reference designators

This file is used by the pick-and-place machine to accurately place components on the PCB during the SMT assembly process.

Importance of Accurate Information in SMT Ordering

Accurate information is essential for efficient SMT ordering and manufacturing processes. Inaccurate or incomplete information can lead to several issues, such as:

- Incorrect component ordering

- Delays in the manufacturing process

- Increased costs due to rework or scrapped materials

- Lower product quality

To avoid these issues, it is crucial to ensure that all the necessary files and information are provided accurately and completely when placing an SMT order.

Best Practices for SMT Ordering

To streamline the SMT ordering process and ensure accurate information is provided, consider the following best practices:

Use a Standard BOM Format

Using a standard BOM format, such as an Excel spreadsheet or CSV file, helps to ensure that all the necessary information is included and organized consistently. This makes it easier for the SMT manufacturer to process the BOM and reduces the risk of errors.

Verify Gerber Files

Before submitting Gerber files for SMT ordering, it is essential to verify that they are accurate and complete. Use Gerber viewer software to check for any errors or discrepancies, such as missing layers or incorrect dimensions.

Provide Clear Assembly Instructions

Include clear and detailed assembly instructions in the assembly drawing to ensure that the SMT manufacturer understands any special requirements or considerations for the assembly process. This can help to prevent mistakes and ensure that the final product meets the desired specifications.

Communicate Any Changes Promptly

If any changes need to be made to the BOM, Gerber files, or assembly drawing after the initial SMT order has been placed, communicate these changes to the manufacturer promptly. This helps to avoid delays and ensures that the final product reflects the most up-to-date specifications.

Work with an Experienced SMT Manufacturer

Partnering with an experienced SMT manufacturer can help to streamline the ordering process and ensure that accurate information is provided. An experienced manufacturer will have the knowledge and expertise to guide you through the process and identify any potential issues before they become problems.

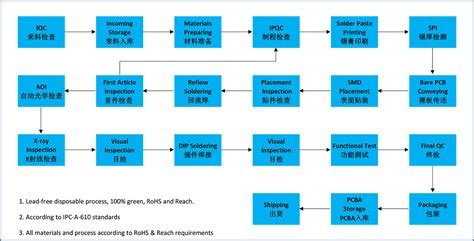

SMT Ordering Process Flow

The SMT ordering process typically follows these steps:

-

Design Finalization: The PCB Design is finalized, and all necessary files (BOM, Gerber files, assembly drawing, and centroid file) are prepared.

-

File Submission: The files are submitted to the SMT manufacturer for review and quoting.

-

Manufacturer Review: The SMT manufacturer reviews the submitted files for accuracy and completeness. If any issues are identified, they will communicate with the customer to resolve them.

-

Quoting: Once the files have been reviewed and approved, the SMT manufacturer generates a quote for the project based on the provided information.

-

Order Placement: If the customer accepts the quote, they place an order with the SMT manufacturer.

-

Manufacturing: The SMT manufacturer begins the manufacturing process, following the provided files and instructions.

-

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the final product meets the required specifications.

-

Shipping: Once the manufacturing process is complete, the finished products are packaged and shipped to the customer.

Conclusion

Accurate information is the foundation of efficient SMT ordering and manufacturing processes. By providing complete and accurate BOM, Gerber files, assembly drawing, and centroid file, customers can ensure that their electronic devices are manufactured to the desired specifications, with minimal delays and errors. Following best practices and partnering with an experienced SMT manufacturer can further streamline the ordering process and ensure successful project outcomes.

Frequently Asked Questions (FAQ)

-

What is the difference between SMT and through-hole technology?

SMT (Surface Mount Technology) involves placing components directly onto the surface of a PCB, while through-hole technology involves inserting component leads through holes in the PCB and soldering them on the opposite side. SMT allows for smaller, more compact designs and faster assembly processes compared to through-hole technology. -

Can I use different file formats for Gerber files?

While the standard Gerber file format is the most widely accepted, some SMT manufacturers may accept other formats such as ODB++ or IPC-2581. It is best to check with your chosen manufacturer for their specific file requirements. -

What happens if I need to make changes to my SMT order after placing it?

If changes need to be made after an order has been placed, inform your SMT manufacturer as soon as possible. Depending on the stage of the manufacturing process, accommodating changes may result in additional costs or delays. Clear and timely communication is key to minimizing the impact of changes on your project. -

How can I ensure the quality of my SMT order?

To ensure the quality of your SMT order, provide accurate and complete information, work with an experienced manufacturer, and communicate openly throughout the process. Many SMT manufacturers also offer quality control services, such as automated optical inspection (AOI) and X-ray inspection, to identify and address any issues before the final product is shipped. -

What should I consider when selecting an SMT manufacturer?

When choosing an SMT manufacturer, consider factors such as their experience, capabilities, quality control processes, communication, and customer support. Look for a manufacturer that has experience with projects similar to yours and can provide the necessary services and support to ensure a successful outcome. Requesting quotes from multiple manufacturers and reviewing their references and portfolios can also help you make an informed decision.

No responses yet