What are SMD LEDs?

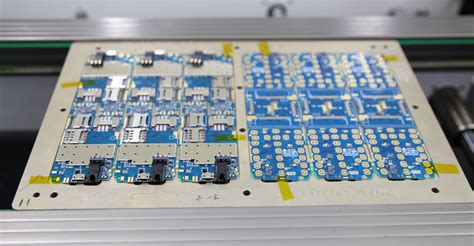

SMD LEDs, or Surface Mounted Device Light Emitting Diodes, are one of the most common types of LED packages used in PCB assembly. These LEDs are small, compact, and designed to be directly soldered onto the surface of a printed circuit board. SMD LEDs come in various sizes, with some of the most popular being 0402, 0603, 0805, and 1206 packages.

Advantages of SMD LEDs

- Compact size: SMD LEDs are incredibly small, allowing for higher-density PCB designs and more efficient use of board space.

- Wide variety of options: SMD LEDs are available in a wide range of colors, brightness levels, and viewing angles, making them suitable for a diverse range of applications.

- Easy to assemble: Due to their standardized packaging, SMD LEDs are easy to pick and place using automated assembly equipment, resulting in faster production times and lower assembly costs.

- Good heat dissipation: SMD LEDs have a relatively good heat dissipation capability due to their direct contact with the PCB surface, which helps to prolong their lifespan.

Disadvantages of SMD LEDs

- Limited power handling: SMD LEDs are not suitable for high-power applications due to their small size and limited heat dissipation capabilities.

- Potential for color inconsistency: Due to variations in the manufacturing process, SMD LEDs from different batches may exhibit slight color inconsistencies, which can be problematic for applications requiring precise color matching.

What are COB LEDs?

COB LEDs, or Chip on Board Light Emitting Diodes, are a type of LED package where multiple LED chips are directly mounted onto a substrate and then encapsulated with a layer of phosphor and epoxy resin. This packaging method allows for a higher density of LED chips in a single package, resulting in increased brightness and improved color consistency compared to SMD LEDs.

Advantages of COB LEDs

- High brightness: COB LEDs can achieve much higher luminous flux than SMD LEDs due to the higher density of LED chips in a single package.

- Improved color consistency: Since the LED chips are encapsulated together, COB LEDs offer better color consistency compared to SMD LEDs, making them ideal for applications requiring uniform illumination.

- Better heat dissipation: COB LEDs have a larger surface area in contact with the PCB, allowing for better heat dissipation and improved thermal management.

- Simplified optics design: The compact and uniform light source of COB LEDs simplifies the design of secondary optics, such as lenses and reflectors.

Disadvantages of COB LEDs

- Higher cost: COB LEDs are generally more expensive than SMD LEDs due to their more complex manufacturing process and higher component cost.

- Limited size options: COB LEDs are typically larger than SMD LEDs, which may not be suitable for applications with strict size constraints.

- Reduced flexibility in design: The fixed arrangement of LED chips in a COB package limits the flexibility in terms of LED placement and layout on the PCB.

What are DOB LEDs?

DOB LEDs, or Direct on Board Light Emitting Diodes, are a relatively new packaging technology where the LED chips are directly mounted onto the PCB without any additional substrate or packaging. This approach eliminates the need for a separate LED package, resulting in a more compact and cost-effective solution.

Advantages of DOB LEDs

- Lower cost: By eliminating the need for a separate LED package, DOB LEDs can significantly reduce the overall cost of the LED PCB assembly.

- Improved thermal performance: Since the LED chips are directly mounted on the PCB, DOB LEDs offer excellent heat dissipation, which can help to increase the lifespan and reliability of the LEDs.

- Compact design: DOB LEDs enable ultra-thin and compact PCB designs, making them ideal for applications with limited space, such as backlighting for displays and indicators.

- Customizable layout: With DOB LEDs, designers have more freedom to arrange the LED chips on the PCB in custom patterns and layouts to achieve the desired illumination effect.

Disadvantages of DOB LEDs

- Increased manufacturing complexity: The process of directly mounting LED chips onto the PCB requires specialized equipment and expertise, which can increase the manufacturing complexity and setup costs.

- Limited power handling: Like SMD LEDs, DOB LEDs are not suitable for high-power applications due to their limited heat dissipation capabilities.

- Potential for chip damage: During the assembly process, the LED chips are exposed and vulnerable to damage from handling and environmental factors, which can impact the yield and reliability of the final product.

Comparison Table

| Feature | SMD LEDs | COB LEDs | DOB LEDs |

|---|---|---|---|

| Size | Small | Large | Small |

| Brightness | Moderate | High | Moderate |

| Color Consistency | Moderate | High | Moderate |

| Heat Dissipation | Good | Excellent | Excellent |

| Cost | Low | High | Low |

| Design Flexibility | High | Low | High |

| Power Handling | Low | High | Low |

| Manufacturing Complexity | Low | Moderate | High |

FAQ

-

Q: Which LED packaging option is best for my application?

A: The choice of LED packaging depends on your specific application requirements, such as size constraints, brightness needs, color consistency, thermal management, and budget. Consider the advantages and disadvantages of each option and consult with an experienced LED PCB manufacturer to determine the best solution for your project. -

Q: Can I mix different types of LED packages on the same PCB?

A: Yes, it is possible to use a combination of SMD, COB, and DOB LEDs on the same PCB. However, keep in mind that each type of LED may require different drive currents, voltages, and thermal management strategies, which can increase the complexity of the PCB design and assembly process. -

Q: Are there any special considerations for designing PCBs with DOB LEDs?

A: When designing PCBs with DOB LEDs, it is important to pay close attention to the thermal management and protection of the exposed LED chips. Ensure that the PCB layout provides adequate heat dissipation and consider using conformal coating or other protective measures to shield the LED chips from environmental factors such as moisture and contaminants. -

Q: How do I choose the right size of SMD LED for my application?

A: The choice of SMD LED size depends on factors such as the required brightness, available PCB space, and power consumption. Smaller packages like 0402 and 0603 are suitable for low-power and space-constrained applications, while larger packages like 0805 and 1206 can handle higher currents and offer better heat dissipation. Consult the LED manufacturer’s datasheets and work with your PCB assembly partner to select the appropriate size for your needs. -

Q: Are COB LEDs suitable for outdoor applications?

A: Yes, COB LEDs can be used in outdoor applications, provided that they are properly protected from environmental factors such as moisture, dust, and extreme temperatures. Encapsulating the COB LED with a suitable resin or using a weatherproof housing can help to ensure reliable operation in outdoor conditions. Additionally, consider using COB LEDs with high IP ratings and robust thermal management for best performance and longevity in outdoor environments.

Conclusion

Choosing the right LED packaging option for your PCB design is crucial for achieving the desired performance, reliability, and cost-effectiveness of your LED application. SMD LEDs offer a compact and versatile solution for a wide range of applications, while COB LEDs excel in high-brightness and color-consistent applications. DOB LEDs provide a cost-effective and compact alternative for space-constrained designs, but come with increased manufacturing complexity.

By understanding the advantages and limitations of each option and carefully considering your specific application requirements, you can make an informed decision and select the best LED packaging solution for your LED PCB project. Working closely with an experienced LED PCB manufacturer can also help you navigate the design and assembly challenges and ensure the success of your LED application.

No responses yet