Introduction to PCB GERBER Files

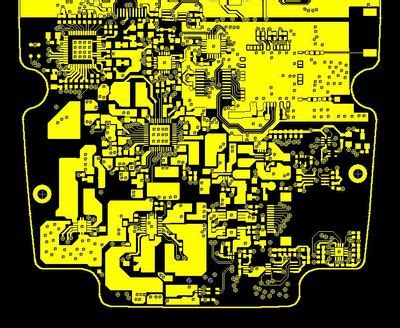

PCB (Printed Circuit Board) GERBER files are a standard file format used in the electronics industry for the design and manufacture of PCBs. GERBER files contain the necessary information for the fabrication of PCBs, including the copper layers, solder mask, silkscreen, and drill data. These files are generated by PCB design software and are used by PCB manufacturers to produce the physical boards.

What are PCB GERBER Files?

PCB GERBER files are a set of files that contain the data required to manufacture a PCB. They are named after the Gerber Scientific Instrument Company, which developed the format in the 1960s. GERBER files are now an industry standard and are supported by all major PCB design software packages.

A typical set of GERBER files for a two-layer PCB includes:

- Top copper layer (e.g., top.gbr)

- Bottom copper layer (e.g., bottom.gbr)

- Top solder mask (e.g., top_mask.gbr)

- Bottom solder mask (e.g., bottom_mask.gbr)

- Top silkscreen (e.g., top_silk.gbr)

- Bottom silkscreen (e.g., bottom_silk.gbr)

- Drill data (e.g., drill.drl)

Importance of PCB GERBER Files

PCB GERBER files are crucial for the accurate and efficient manufacture of PCBs. They provide a standardized format for communicating the design intent between the PCB designer and the manufacturer. By using GERBER files, designers can ensure that their designs are accurately reproduced, and manufacturers can streamline their production processes.

Reverse Engineering PCB GERBER Files

Reverse engineering PCB GERBER files involves analyzing the files to extract design information and recreate the original PCB design. This process is useful in various scenarios, such as:

- Legacy product support: When the original design files are lost or unavailable, reverse engineering can help recreate the design for maintenance or upgrades.

- Competitive analysis: Companies may reverse engineer competitor’s products to understand their design and functionality.

- Learning and education: Reverse engineering PCB GERBER files can be a valuable learning experience for students and hobbyists interested in PCB design.

Steps to Reverse Engineer PCB GERBER Files

-

Obtain the GERBER files: Acquire the complete set of GERBER files for the PCB you wish to reverse engineer. These files can be obtained by requesting them from the manufacturer or extracting them from the PCB design software if available.

-

Import the files into a PCB design software: Open the GERBER files using a compatible PCB design software, such as KiCad, Eagle, or Altium Designer. Most software packages have built-in tools for importing GERBER files.

-

Analyze the layers: Examine each layer of the imported PCB design to understand the layout, components, and interconnections. Pay attention to the copper layers, solder mask, and silkscreen to identify the various elements of the design.

-

Identify components: Use the silkscreen layer and your knowledge of electronic components to identify the components used in the design. Create a bill of materials (BOM) listing all the components and their specifications.

-

Trace the connections: Follow the copper traces to understand how the components are interconnected. Create a schematic diagram representing the logical connections between the components.

-

Recreate the design: Using the information gathered from the analysis, recreate the PCB design in the PCB design software. This process involves placing the components, routing the traces, and adding any necessary design elements such as mounting holes or text.

-

Verify the design: Compare the recreated design with the original GERBER files to ensure accuracy. Perform any necessary revisions or adjustments to match the original design as closely as possible.

Tools for Reverse Engineering PCB GERBER Files

Several software tools are available to assist in the reverse engineering process of PCB GERBER files. Some popular options include:

| Tool | Description |

|---|---|

| KiCad | Free and open-source PCB design software with GERBER import capabilities |

| Eagle | Popular PCB design software with GERBER import and export features |

| Altium Designer | Professional PCB design software with advanced GERBER handling capabilities |

| Gerbv | Free and open-source Gerber viewer for analyzing GERBER files |

| GerberLogix | Commercial software for visualizing and analyzing GERBER files |

These tools provide various features for importing, viewing, and analyzing GERBER files, making the reverse engineering process more efficient and accurate.

Challenges in Reverse Engineering PCB GERBER Files

Reverse engineering PCB GERBER files can be a complex and time-consuming process. Some of the challenges involved include:

Incomplete or corrupted files

The success of reverse engineering depends on the availability and quality of the GERBER files. If the files are incomplete or corrupted, it may be difficult or impossible to accurately recreate the original design. Common issues include missing layers, incorrect file formats, or damaged files.

Component identification

Identifying the components used in the PCB design can be challenging, especially if the silkscreen layer is missing or incomplete. In some cases, the components may be custom or proprietary, making it difficult to find their specifications or replacements.

Complex designs

PCBs with high component density, fine-pitch traces, or multi-layer stackups can be more challenging to reverse engineer. The complexity of the design may require advanced PCB design skills and tools to accurately recreate the original layout.

Design rules and constraints

The original PCB design may have followed specific design rules and constraints, such as minimum trace widths, clearances, or via sizes. These rules may not be explicitly stated in the GERBER files, requiring the reverse engineer to make educated guesses or assumptions based on the observed layout.

Intellectual property concerns

Reverse engineering a PCB design may raise intellectual property concerns, especially if the design is protected by patents or copyrights. It is essential to ensure that the reverse engineering process complies with applicable laws and regulations.

Best Practices for Reverse Engineering PCB GERBER Files

To overcome the challenges and ensure a successful reverse engineering process, consider the following best practices:

-

Verify the completeness and quality of the GERBER files: Before starting the reverse engineering process, ensure that you have a complete set of GERBER files and that they are not corrupted or damaged. If possible, request the files directly from the manufacturer or the original designer.

-

Use high-quality PCB design software: Invest in a reliable and feature-rich PCB design software that supports GERBER import and export. Good software will provide tools for visualizing and analyzing the files, making the reverse engineering process more efficient.

-

Reference datasheets and component libraries: When identifying components, refer to their datasheets and compare them with the observed footprints and markings. Use component libraries in the PCB design software to find matching components or create custom footprints if necessary.

-

Collaborate with experienced PCB designers: If you encounter difficulties or uncertainties during the reverse engineering process, seek assistance from experienced PCB designers. They can provide valuable insights and guidance based on their knowledge and experience.

-

Document the process and findings: Maintain detailed documentation of the reverse engineering process, including the steps followed, assumptions made, and any challenges encountered. This documentation will be valuable for future reference and can help others understand the recreated design.

-

Verify the recreated design: After recreating the PCB design, compare it with the original GERBER files to ensure accuracy. Perform a visual inspection and use automated comparison tools if available. If possible, fabricate a prototype of the recreated design and test it to validate its functionality.

-

Respect intellectual property: Be mindful of intellectual property rights when reverse engineering PCB designs. Ensure that you have the necessary permissions or licenses to reverse engineer and use the design. If in doubt, consult with legal experts to avoid potential infringement issues.

Frequently Asked Questions (FAQ)

- What are the essential files required for reverse engineering a PCB?

-

The essential files for reverse engineering a PCB are the GERBER files, which include the copper layers, solder mask, silkscreen, and drill data. Having a complete set of GERBER files is crucial for accurately recreating the original design.

-

Can I reverse engineer a PCB without the silkscreen layer?

-

While it is possible to reverse engineer a PCB without the silkscreen layer, it can be more challenging. The silkscreen layer provides valuable information about component placement and identification. In the absence of the silkscreen, you may need to rely on the component footprints and your knowledge of electronic components to identify them.

-

What should I do if I encounter missing or damaged GERBER files?

-

If you encounter missing or damaged GERBER files, try to obtain a complete set from the manufacturer or the original designer. If that is not possible, you may need to make educated guesses or assumptions based on the available information. In some cases, you may need to redesign certain portions of the PCB to fill in the missing information.

-

How accurate is the reverse-engineered PCB design compared to the original?

-

The accuracy of the reverse-engineered PCB design depends on various factors, such as the quality of the GERBER files, the complexity of the design, and the skills of the reverse engineer. By following best practices and using high-quality tools, it is possible to achieve a high degree of accuracy. However, it is important to verify the recreated design against the original files and, if possible, fabricate a prototype to validate its functionality.

-

Are there any legal concerns with reverse engineering PCB designs?

- Reverse engineering PCB designs may raise legal concerns, particularly if the design is protected by patents, copyrights, or other intellectual property rights. It is essential to ensure that you have the necessary permissions or licenses to reverse engineer and use the design. If you are unsure about the legal implications, consult with legal experts to avoid potential infringement issues.

Conclusion

Reverse engineering PCB GERBER files is a valuable skill for engineers, hobbyists, and researchers who need to understand or recreate existing PCB designs. By following the steps outlined in this article and using the appropriate tools and best practices, you can successfully reverse engineer PCB designs from GERBER files.

However, it is essential to be aware of the challenges involved, such as incomplete files, component identification, complex designs, and intellectual property concerns. By addressing these challenges and seeking assistance when needed, you can overcome the obstacles and achieve accurate results.

As with any engineering project, documentation and verification are crucial to the success of reverse engineering PCB GERBER files. Maintain detailed records of your process, assumptions, and findings, and always compare the recreated design with the original files to ensure accuracy.

By mastering the art of reverse engineering PCB GERBER files, you can unlock valuable insights into existing designs, support legacy products, and expand your PCB design skills. Whether you are a professional engineer or a curious hobbyist, the ability to reverse engineer PCBs from GERBER files is a powerful tool in your arsenal.

No responses yet