Introduction

Printed circuit boards (PCBs) are an essential component of modern electronics. They provide the physical structure and electrical interconnections for electronic components in devices ranging from smartphones to industrial equipment. However, you may have also heard the term “printed wiring board” or PWB used to refer to these boards. So what’s the difference between a PWB and PCB? Is one term more technically correct than the other? In this article, we’ll explore the history and usage of these terms to determine which is the standard term for referring to circuit boards.

What is a Printed Circuit Board (PCB)?

A printed circuit board, or PCB, is a flat board made of insulating material with conductive copper traces printed onto it. Electronic components are soldered onto the board to create a complete circuit. PCBs provide both mechanical support and electrical connections for the components.

Anatomy of a PCB

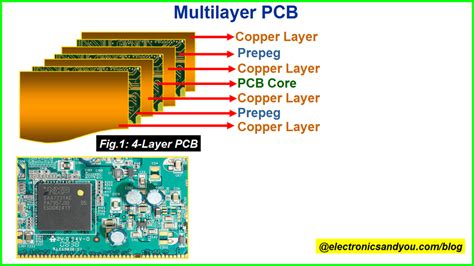

A typical PCB consists of several layers:

- Substrate – The base material, usually FR4 fiberglass

- Copper – Thin copper foil bonded to the substrate. The copper is etched away to form traces.

- Solder mask – Insulating layer that covers the copper, with openings for solder pads

- Silkscreen – Text and symbols printed on the solder mask for labels and instructions

- Surface finish – Protective coating on exposed copper to prevent oxidation

Image source: ProtoExpress

Types of PCBs

PCBs can be categorized based on the number of conductive layers:

| Type | Layers | Applications |

|---|---|---|

| Single-sided | 1 | Simple, low-cost devices |

| Double-sided | 2 | Devices with moderate complexity |

| Multi-layer | 3+ | Complex, high-density devices |

PCBs can also be rigid, flexible, or a combination (rigid-flex).

What is a Printed Wiring Board (PWB)?

A printed wiring board, or PWB, is essentially the same thing as a PCB. The term “printed wiring board” was more common in the early days of the technology, but “printed circuit board” has become the more widely used term in recent decades.

History of the Terms

The concept of a printed circuit was first introduced in the early 20th century, but it wasn’t until the 1940s that the technology began to be widely used. During World War II, the United States military started using “printed wiring” to refer to the process of printing conductive traces onto an insulating substrate.

After the war, as the technology became more widely adopted for commercial applications, the term “printed circuit” became more popular. This shift in terminology likely reflects the fact that a complete circuit, not just the wiring, is printed onto the board.

PWB vs PCB: Which Term is Correct?

So, is there a difference between a PWB and a PCB? Technically, no. The two terms refer to the same thing – a board with conductive traces used to mechanically support and electrically connect electronic components.

However, “printed circuit board” or PCB has become the standard term in the industry. If you look at the websites and documentation of major electronics manufacturers and PCB design software companies, you’ll find that they almost exclusively use “PCB.”

That said, “printed wiring board” or PWB is still occasionally used, particularly in military and aerospace contexts. Some argue that PWB is a more precise term, since the board contains printed wiring, not a complete circuit. However, this is a minor distinction, and the vast majority of professionals simply use PCB.

Advantages of Using PCBs

So why are PCBs so widely used in electronics manufacturing? There are several key advantages:

- Compact size – PCBs allow for very dense component placement, enabling smaller devices

- Reliability – Soldered connections on a PCB are more reliable than point-to-point wiring

- Consistency – Automated PCB manufacturing ensures consistency between boards

- Lower cost – Mass production of PCBs is less expensive than hand-wired circuits

- Design flexibility – PCBs can be designed for specific applications and form factors

These benefits have made PCBs an indispensable part of modern electronics.

The PCB Design and Manufacturing Process

Creating a PCB involves several steps:

- Schematic design – The circuit is designed using schematic capture software

- Board layout – The physical layout of the board is created in PCB design software

- Fabrication – The board is manufactured based on the design files

- Assembly – Components are soldered onto the fabricated board

- Testing – The assembled board is tested to ensure proper functionality

Image source: Candor Industries

Advances in PCB design software and manufacturing techniques have made the process faster and more accessible than ever before.

Frequently Asked Questions (FAQ)

1. Are PWBs and PCBs the same thing?

Yes, PWB (printed wiring board) and PCB (printed circuit board) refer to the same thing – a board with conductive traces used to connect electronic components. PCB is the more widely used term in the industry today.

2. What are the different types of PCBs?

PCBs can be categorized based on the number of conductive layers:

– Single-sided (1 layer)

– Double-sided (2 layers)

– Multi-layer (3+ layers)

PCBs can also be rigid, flexible, or a combination (rigid-flex).

3. What are the advantages of using PCBs?

The main advantages of using PCBs include:

– Compact size

– Reliability

– Consistency

– Lower cost

– Design flexibility

4. What is the PCB design and manufacturing process?

The main steps in PCB design and manufacturing are:

1. Schematic design

2. Board layout

3. Fabrication

4. Assembly

5. Testing

5. Why did the term shift from PWB to PCB?

The term “printed wiring board” or PWB was more common in the early days of the technology, particularly in military applications. As the technology became more widely adopted for commercial use, “printed circuit board” or PCB became the preferred term, likely because it reflects the fact that a complete circuit, not just wiring, is printed on the board.

Conclusion

In summary, while you may occasionally hear the term “printed wiring board” or PWB, “printed circuit board” or PCB is by far the more common and widely accepted term in the industry today. The two terms refer to the same thing, and the shift in terminology likely reflects the evolution of the technology from simple printed wiring to complete printed circuits.

PCBs have revolutionized electronics manufacturing, enabling smaller, more reliable, and more affordable devices. As PCB design and manufacturing techniques continue to advance, we can expect to see even more innovative applications of this crucial technology in the future.

No responses yet