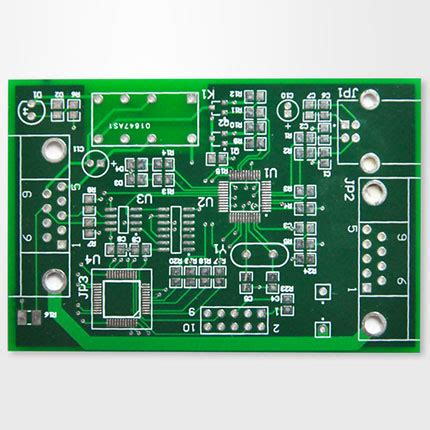

What is a PCB Prototype?

A PCB (Printed Circuit Board) prototype is a preliminary version of a PCB designed to test and validate the functionality, performance, and manufacturability of the board before mass production. It is an essential step in the development process of electronic devices, allowing engineers to identify and rectify any issues or defects early on, saving time and costs in the long run.

PCB prototypes are typically fabricated in small quantities, ranging from a single unit to a few dozen, depending on the complexity of the design and the testing requirements. They are made using the same materials and processes as the final production boards but may have some modifications or simplifications to expedite the prototyping process.

Why is PCB Prototyping Important?

PCB prototyping is crucial for several reasons:

-

Design Validation: Prototypes allow engineers to test the functionality and performance of the PCB design in real-world conditions. This helps identify any design flaws, such as signal integrity issues, power distribution problems, or component compatibility issues, which can be addressed before moving to mass production.

-

Component Testing: Prototyping enables engineers to test the suitability and reliability of the selected components, ensuring they meet the required specifications and perform as expected under various environmental conditions.

-

Manufacturing Process Optimization: By fabricating prototypes, manufacturers can optimize the production process, identifying any potential issues with the assembly, soldering, or testing procedures. This helps streamline the mass production process, reducing the likelihood of defects and improving overall quality.

-

Cost Reduction: Identifying and rectifying issues during the prototyping stage is much more cost-effective than discovering problems during mass production. Prototyping helps minimize the risk of costly rework, scrap, or product recalls.

-

Time-to-Market: PCB prototyping allows for faster iteration and refinement of the design, enabling companies to bring their products to market more quickly. This is particularly important in today’s competitive electronics industry, where time-to-market can be a critical factor in a product’s success.

The PCB Prototyping Process

The PCB prototyping process typically involves the following steps:

-

Schematic Design: Engineers create a schematic diagram of the electronic circuit, specifying the components, their connections, and the overall functionality of the board.

-

PCB Layout: Using CAD (Computer-Aided Design) software, the schematic is translated into a physical layout of the PCB, determining the placement of components, routing of traces, and creation of copper layers.

-

Design Rule Check (DRC): The PCB layout undergoes a DRC to ensure it adheres to the manufacturing guidelines and constraints, such as minimum trace widths, clearances, and hole sizes.

-

Gerber File Generation: Once the PCB layout is finalized, Gerber files are generated. These are industry-standard files that contain all the necessary information for PCB fabrication, including the copper layers, solder mask, silk screen, and drill data.

-

Fabrication: The Gerber files are sent to a PCB manufacturer, who fabricates the prototype boards using various processes, such as etching, plating, and lamination.

-

Assembly: The fabricated PCB prototypes are then assembled with the specified components, either manually or using automated pick-and-place machines.

-

Testing and Validation: The assembled prototypes undergo rigorous testing to validate their functionality, performance, and reliability. This may include electrical testing, environmental testing, and compatibility testing with other system components.

-

Iteration: Based on the testing results, engineers may need to make modifications to the design, repeating the prototyping process until the desired performance and quality are achieved.

PCB Prototype Manufacturing Techniques

There are several manufacturing techniques used for PCB prototyping, each with its own advantages and limitations. The choice of technique depends on factors such as the complexity of the design, the required turnaround time, and the budget.

1. Subtractive Prototyping

Subtractive prototyping involves removing unwanted copper from a pre-clad PCB substrate to create the desired circuit pattern. The most common subtractive techniques are:

a. Chemical Etching: The PCB is coated with a photoresist layer, which is then exposed to UV light through a photomask containing the circuit pattern. The exposed areas of the photoresist are developed and removed, allowing the unwanted copper to be etched away using a chemical solution.

b. Mechanical Milling: A computer-controlled milling machine is used to remove the unwanted copper from the PCB substrate, leaving behind the desired circuit pattern. This technique is suitable for simple designs and quick turnaround times.

2. Additive Prototyping

Additive prototyping involves depositing conductive material onto the PCB substrate to create the desired circuit pattern. The most common additive techniques are:

a. Inkjet Printing: Conductive ink is printed onto the PCB substrate using an inkjet printer, creating the circuit pattern. This technique is suitable for simple designs and rapid prototyping.

b. Aerosol Jet Printing: A fine mist of conductive material is sprayed onto the PCB substrate using an aerosol jet printer, creating the circuit pattern. This technique offers higher resolution and precision compared to inkjet printing.

3. PCB Milling

PCB milling is a subtractive technique that uses a computer-controlled milling machine to remove unwanted copper from the PCB substrate. It is suitable for creating prototype PCBs with simple to moderate complexity and offers fast turnaround times.

4. PCB Laser Prototyping

PCB laser prototyping uses a high-powered laser to selectively remove unwanted copper from the PCB substrate. This technique offers high precision and can create fine traces and features, making it suitable for complex designs.

Choosing the Right PCB Prototype Manufacturer

Selecting the right PCB prototype manufacturer is crucial for ensuring the quality, reliability, and timely delivery of your prototypes. Consider the following factors when choosing a manufacturer:

-

Capabilities: Ensure the manufacturer has the necessary equipment, expertise, and experience to handle your specific PCB prototyping requirements, such as multi-layer boards, high-density layouts, or specialized materials.

-

Quality Standards: Look for manufacturers that adhere to industry quality standards, such as IPC (Association Connecting Electronics Industries) standards, and have a robust quality control process in place.

-

Turnaround Time: Consider the manufacturer’s typical turnaround times for prototyping and their ability to accommodate urgent requests if needed.

-

Customer Support: Choose a manufacturer that offers responsive and knowledgeable customer support, as you may need assistance with design reviews, file preparation, or troubleshooting during the prototyping process.

-

Pricing: Obtain quotes from multiple manufacturers and compare their pricing, considering factors such as the minimum order quantity, setup fees, and shipping costs.

-

Reputation: Research the manufacturer’s reputation in the industry, read customer reviews, and seek recommendations from colleagues or online forums to gauge their reliability and customer satisfaction.

PCB Prototype Testing and Validation

Once the PCB prototypes are manufactured and assembled, they must undergo thorough testing and validation to ensure they meet the desired performance and quality standards. Some common testing methods include:

-

Visual Inspection: A visual examination of the PCB prototype to check for any obvious defects, such as missing components, solder bridges, or damaged traces.

-

Continuity Testing: Verifying the electrical continuity of the circuits using a multimeter or continuity tester to ensure there are no open or short circuits.

-

Functional Testing: Testing the PCB prototype’s functionality under real-world conditions, using test fixtures or by integrating it into the target system.

-

Environmental Testing: Subjecting the prototype to various environmental conditions, such as temperature extremes, humidity, or vibration, to assess its reliability and durability.

-

Electromagnetic Compatibility (EMC) Testing: Evaluating the prototype’s ability to operate without causing or being affected by electromagnetic interference (EMI).

-

Signal Integrity Testing: Analyzing the quality of the signals transmitted through the PCB, ensuring they maintain their integrity and timing characteristics.

-

Boundary Scan Testing: Using built-in test circuits and JTAG (Joint Test Action Group) interfaces to test the connectivity and functionality of the components on the PCB.

Based on the testing results, engineers may need to make modifications to the design and repeat the prototyping process until the desired performance and quality are achieved.

Frequently Asked Questions (FAQ)

1. How long does it take to manufacture a PCB prototype?

The turnaround time for PCB prototyping depends on various factors, such as the complexity of the design, the chosen manufacturing technique, and the manufacturer’s workload. Generally, simple designs can be prototyped within 1-2 days, while more complex designs may take 5-7 days or longer.

2. How much does it cost to manufacture a PCB prototype?

The cost of PCB prototyping varies based on factors such as the board size, layer count, component density, and the quantity of prototypes required. Simple, single-layer prototypes may cost as little as $50, while complex, multi-layer designs can cost several hundred dollars or more. Many manufacturers offer discounts for higher quantities.

3. What files are needed for PCB prototyping?

To manufacture a PCB prototype, you typically need to provide the following files:

- Gerber files: These include the copper layers, solder mask, silk screen, and drill data.

- Bill of Materials (BOM): A list of all the components used on the PCB, including their reference designators, part numbers, and quantities.

- Assembly drawings: Illustrations showing the placement and orientation of components on the PCB.

4. Can PCB prototypes be used for final production?

While PCB prototypes are primarily used for testing and validation, they can sometimes be used for final production if they meet all the required specifications and quality standards. However, it is generally recommended to perform a pilot production run before moving to full-scale mass production to ensure the manufacturability and reliability of the design.

5. What are the benefits of using a Turnkey PCB prototype service?

Turnkey PCB prototype services offer several benefits, including:

- One-stop solution: They handle the entire prototyping process, from PCB fabrication to component sourcing and assembly, simplifying the process for the customer.

- Time-saving: By outsourcing the prototyping process, companies can focus on their core competencies and reduce the time spent on managing multiple suppliers.

- Expertise: Turnkey service providers have the necessary expertise and experience to handle complex PCB designs and ensure high-quality results.

- Cost-effective: Outsourcing the prototyping process can be more cost-effective than maintaining an in-house facility, especially for low-volume production.

In conclusion, PCB prototyping is a critical step in the development of electronic devices, enabling engineers to test, validate, and optimize their designs before moving to mass production. By carefully selecting the appropriate manufacturing technique, working with a reputable PCB prototype manufacturer, and conducting thorough testing and validation, companies can ensure the success of their electronic products while minimizing development time and costs.

| PCB Prototyping Technique | Advantages | Limitations |

|---|---|---|

| Chemical Etching | – Suitable for complex designs – High precision – Batch production |

– Longer turnaround time – Higher setup costs – Environmental concerns |

| Mechanical Milling | – Fast turnaround time – Low setup costs – Suitable for simple designs |

– Limited precision – Not suitable for complex designs |

| Inkjet Printing | – Fast turnaround time – Low setup costs – Suitable for simple designs |

– Limited precision – Limited material options |

| Aerosol Jet Printing | – High precision – Fine feature resolution – Various material options |

– Higher setup costs – Slower than other additive techniques |

| PCB Milling | – Fast turnaround time – Suitable for simple to moderate complexity |

– Limited precision compared to etching – Tool wear and breakage |

| PCB Laser Prototyping | – High precision – Fine feature resolution – Suitable for complex designs |

– Higher setup costs – Slower than milling |

Table: Comparison of PCB Prototyping Techniques

No responses yet