Introduction to PCB Manufacturing in the UK

The United Kingdom has a rich history in the electronics industry, and PCB manufacturing has been a significant part of this sector for decades. PCB, or Printed Circuit Board, is the backbone of modern electronics, found in almost every electronic device we use today. From smartphones and computers to medical devices and aerospace systems, PCBs play a crucial role in ensuring the proper functioning and reliability of these devices.

In this comprehensive guide, we will explore the world of PCB manufacturing in the UK, discussing the advantages of working with UK-based PCB manufacturers, the different types of PCBs available, and the factors to consider when choosing a PCB manufacturer. We will also provide a list of top PCB manufacturers in the UK and answer some frequently asked questions about PCB manufacturing.

Advantages of Working with UK-Based PCB Manufacturers

When it comes to sourcing PCBs for your electronics projects, there are several reasons why working with a UK-based PCB manufacturer can be advantageous:

1. High-Quality Standards

The UK has a reputation for producing high-quality products, and PCB manufacturing is no exception. UK-based PCB manufacturers adhere to strict quality control measures and industry standards, ensuring that the PCBs they produce are of the highest quality and reliability.

2. Skilled Workforce

The UK has a highly skilled and experienced workforce in the electronics industry, with many professionals having years of expertise in PCB design and manufacturing. This means that UK-based PCB manufacturers can provide valuable insights and support throughout the PCB development process, from design to production.

3. Shorter Lead Times

When working with a UK-based PCB manufacturer, you can benefit from shorter lead times compared to sourcing PCBs from overseas. This is because the proximity of the manufacturer allows for faster delivery and reduces the risk of delays due to customs or shipping issues.

4. Better Communication

Collaborating with a UK-based PCB manufacturer allows for better communication and easier coordination. With no language barriers or significant time zone differences, you can easily discuss your project requirements, receive updates, and address any concerns in real-time.

5. Support for Low-Volume Production

Many UK-based PCB manufacturers offer support for low-volume production runs, which is particularly beneficial for startups, small businesses, and R&D projects. This flexibility allows you to prototype and test your designs without the need for large-scale production commitments.

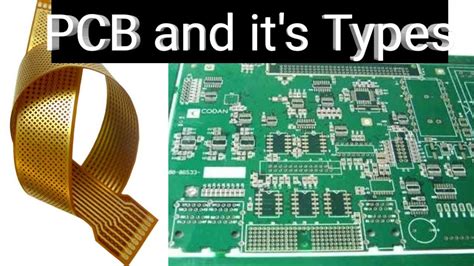

Types of PCBs Available in the UK

UK-based PCB manufacturers offer a wide range of PCB Types to suit different applications and requirements. Some of the most common types of PCBs available in the UK include:

1. Single-Sided PCBs

Single-sided PCBs have conductive traces on only one side of the board. They are the simplest and most cost-effective type of PCB, suitable for basic electronic circuits and low-density designs.

2. Double-Sided PCBs

Double-sided PCBs have conductive traces on both sides of the board, allowing for more complex circuits and higher component density. They often include through-hole connections called vias to connect the traces on both sides.

3. Multi-Layer PCBs

Multi-layer PCBs consist of three or more conductive layers separated by insulating layers. They offer the highest level of complexity and density, enabling the design of advanced electronic systems. Multi-layer PCBs are commonly used in applications such as telecommunications, aerospace, and medical devices.

4. Flexible PCBs

Flexible PCBs are made from flexible materials, such as polyimide, allowing them to bend and conform to different shapes. They are ideal for applications that require flexibility or where space is limited, such as wearable electronics and automotive systems.

5. Rigid-Flex PCBs

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs. They consist of rigid PCB sections connected by flexible PCB sections, providing the stability of a rigid board and the flexibility needed for certain design requirements.

6. High-Frequency PCBs

High-frequency PCBs are designed to handle high-speed signals and minimize signal integrity issues. They are made using special materials and techniques to reduce signal loss and maintain signal integrity at high frequencies. High-frequency PCBs are used in applications such as RF systems, radar, and high-speed digital circuits.

| PCB Type | Layers | Flexibility | Application Examples |

|---|---|---|---|

| Single-Sided | 1 | Rigid | Simple electronic circuits, low-density designs |

| Double-Sided | 2 | Rigid | More complex circuits, higher component density |

| Multi-Layer | 3+ | Rigid | Advanced electronic systems, telecommunications, aerospace, medical devices |

| Flexible | 1-2 | Flexible | Wearable electronics, automotive systems |

| Rigid-Flex | 2+ | Rigid and Flexible | Complex designs requiring both stability and flexibility |

| High-Frequency | 1+ | Rigid | RF systems, radar, high-speed digital circuits |

Factors to Consider When Choosing a PCB Manufacturer in the UK

When selecting a PCB manufacturer in the UK, there are several factors to consider to ensure that you find the right partner for your project:

1. Capabilities and Expertise

Evaluate the PCB manufacturer’s capabilities and expertise in relation to your project requirements. Consider their experience in manufacturing the specific type of PCB you need, as well as their ability to handle the complexity and scale of your project.

2. Quality Control and Certifications

Look for PCB manufacturers with robust quality control processes and relevant certifications, such as ISO 9001, ISO 14001, and UL. These certifications demonstrate the manufacturer’s commitment to quality, reliability, and environmental responsibility.

3. Turnaround Time and Delivery

Consider the PCB manufacturer’s turnaround time and delivery options. Can they meet your project deadlines? Do they offer expedited services if needed? Also, inquire about their shipping methods and costs, especially if you require international delivery.

4. Customer Support and Communication

Evaluate the level of customer support and communication provided by the PCB manufacturer. Do they have a dedicated support team to assist you throughout the project? Are they responsive to your inquiries and provide timely updates?

5. Pricing and Value for Money

Compare pricing among different PCB manufacturers, but also consider the value for money they offer. While cost is an important factor, it should not be the sole deciding factor. Look for a manufacturer that provides a balance of quality, reliability, and affordability.

Top PCB Manufacturers in the UK

Here is a list of some of the top PCB manufacturers in the UK:

- Eurocircuits (UK Division)

- Website: www.eurocircuits.com

- Location: Bristol

-

Specialties: Prototyping, small to medium-volume production, quick turnaround

-

PCB Train

- Website: www.pcbtrain.co.uk

- Location: Hertfordshire

-

Specialties: Prototype and production PCBs, flexible and rigid-flex PCBs

-

PCB Solutions Ltd

- Website: www.pcbsolutionsltd.co.uk

- Location: West Sussex

-

Specialties: Quick-turn prototypes, multi-layer PCBs, high-frequency PCBs

-

UK Circuits

- Website: www.ukcircuits.co.uk

- Location: Tyne and Wear

-

Specialties: Single to multi-layer PCBs, flexible PCBs, assembly services

-

Merlin Circuit Technology Ltd

- Website: www.merlincircuit.co.uk

- Location: Hawarden

-

Specialties: Rapid prototyping, high-reliability PCBs, aerospace and defense applications

-

European Circuits Ltd

- Website: www.european-circuits.co.uk

- Location: Cumbernauld

-

Specialties: Prototype and production PCBs, multi-layer PCBs, IPC-certified

-

Graphic Plc

- Website: www.graphic.plc.uk

- Location: Devon

- Specialties: Advanced PCB solutions, high-density interconnects, aerospace and defense applications

| Manufacturer | Location | Specialties |

|---|---|---|

| Eurocircuits (UK Division) | Bristol | Prototyping, small to medium-volume production, quick turnaround |

| PCB Train | Hertfordshire | Prototype and production PCBs, flexible and rigid-flex PCBs |

| PCB Solutions Ltd | West Sussex | Quick-turn prototypes, multi-layer PCBs, high-frequency PCBs |

| UK Circuits | Tyne and Wear | Single to multi-layer PCBs, flexible PCBs, assembly services |

| Merlin Circuit Technology Ltd | Hawarden | Rapid prototyping, high-reliability PCBs, aerospace and defense applications |

| European Circuits Ltd | Cumbernauld | Prototype and production PCBs, multi-layer PCBs, IPC-certified |

| Graphic Plc | Devon | Advanced PCB solutions, high-density interconnects, aerospace and defense applications |

Frequently Asked Questions (FAQ)

1. What is the typical turnaround time for PCB manufacturing in the UK?

The turnaround time for PCB manufacturing in the UK varies depending on the complexity of the design, the type of PCB, and the manufacturer’s workload. However, most UK-based PCB manufacturers offer standard lead times of 5-10 working days for prototype and small-volume production. Some manufacturers also provide expedited services for urgent projects, with turnaround times as short as 24-48 hours.

2. Can UK-based PCB manufacturers handle both prototype and large-scale production?

Yes, many UK-based PCB manufacturers have the capability to handle both prototype and large-scale production. Some manufacturers specialize in quick-turn prototyping services, while others focus on high-volume production runs. It’s essential to discuss your specific project requirements with the manufacturer to ensure they can meet your needs.

3. Do UK-based PCB manufacturers offer assembly services?

Yes, several UK-based PCB manufacturers offer assembly services in addition to PCB fabrication. These services can include through-hole and surface-mount assembly, component sourcing, and testing. Opting for a manufacturer that provides both PCB fabrication and assembly services can streamline your project and reduce overall lead times.

4. Are UK-based PCB manufacturers competitive in terms of pricing?

UK-based PCB manufacturers are generally competitive in terms of pricing, especially when considering the high quality of their products and services. While offshore manufacturers may offer lower prices, working with a UK-based manufacturer can provide advantages such as faster turnaround times, better communication, and easier quality control. It’s important to evaluate the total cost of ownership, including factors such as shipping costs, potential delays, and the cost of quality issues.

5. How can I ensure that my PCB design is manufacturable?

To ensure that your PCB design is manufacturable, it’s crucial to follow industry-standard design guidelines and consult with your chosen PCB manufacturer early in the design process. Most UK-based PCB manufacturers offer design support services and can provide feedback on your design’s manufacturability, helping you to identify and address potential issues before production begins. Adhering to the manufacturer’s design rules and guidelines can help to minimize the risk of production delays and quality issues.

Conclusion

The UK has a strong and thriving PCB manufacturing industry, with numerous high-quality PCB manufacturers offering a wide range of services and capabilities. When selecting a PCB manufacturer in the UK, it’s essential to consider factors such as their expertise, quality control processes, turnaround times, customer support, and pricing. By partnering with a reputable UK-based PCB manufacturer, you can benefit from their skills, experience, and commitment to delivering high-quality PCBs for your electronics projects.

As you embark on your PCB manufacturing journey in the UK, remember to communicate your project requirements clearly, work closely with your chosen manufacturer, and take advantage of their design support services to ensure the success of your project. With the right PCB manufacturer by your side, you can bring your electronic designs to life and contribute to the ongoing growth and innovation of the UK’s electronics industry.

No responses yet