Introduction to PCB and Wired Printing Head

A PCB (Printed Circuit Board) is a fundamental component in modern electronics, serving as a base for mounting and connecting electronic components. In the context of 3D printing, a PCB plays a crucial role in controlling the wired printing head of a Fabtotum printer. The wired printing head is responsible for extruding the filament and creating the desired 3D object layer by layer.

How PCB Facilitates Wired Printing Head Function

The PCB in a Fabtotum printer is designed to control and regulate the functions of the wired printing head. It houses various electronic components, such as microcontrollers, drivers, and connectors, which work together to ensure precise and reliable printing performance.

| Component | Function |

|---|---|

| Microcontroller | Controls the overall operation of the printing head |

| Stepper Drivers | Regulate the movement of the stepper motors |

| Temperature Sensor | Monitors the temperature of the printing head |

| Heater Cartridge | Heats the printing head to the required temperature |

| Connector | Establishes a connection between the PCB and printing head |

Benefits of Using a PCB in Wired Printing Head

-

Compact Design: A well-designed PCB allows for a compact and organized arrangement of electronic components, reducing the overall size of the printing head assembly.

-

Reliable Connections: PCBs provide a stable and reliable means of connecting various components, minimizing the risk of loose connections or wiring issues.

-

Efficient Heat Management: The PCB can be designed to efficiently dissipate heat generated by the printing head, ensuring optimal performance and longevity.

-

Customization Options: PCBs can be customized to accommodate specific requirements of the Fabtotum printer, such as additional sensors or communication modules.

PCB Design Considerations for Wired Printing Head

Choosing the Right PCB Material

When designing a PCB for a wired printing head, it is essential to select the appropriate PCB material. The most common materials used are:

-

FR-4: A glass-reinforced epoxy laminate, FR-4 is the most widely used PCB material due to its excellent mechanical and electrical properties.

-

Aluminum: Aluminum PCBs offer superior heat dissipation capabilities, making them suitable for applications that generate significant heat, such as 3D printing.

-

Flexible PCBs: Flexible PCBs, made from materials like Kapton or Polyimide, can be used in applications that require the PCB to conform to a specific shape or withstand repeated flexing.

PCB Layer Stack-up

The layer stack-up of a PCB refers to the arrangement of copper layers and insulating materials. For a wired printing head PCB, a typical layer stack-up might include:

| Layer | Description |

|---|---|

| Top Layer | Contains components and primary signal routing |

| Ground Plane | Provides a low-impedance ground reference |

| Power Plane | Distributes power to various components |

| Bottom Layer | Accommodates additional components and signal routing |

Component Placement and Routing

Proper component placement and routing are crucial for optimal PCB performance. Consider the following guidelines:

-

Component Placement: Place components in a logical and organized manner, keeping in mind the flow of signals and the need for efficient heat dissipation.

-

Signal Routing: Route signals using the shortest possible paths to minimize signal integrity issues. Avoid sharp angles and maintain proper spacing between traces to reduce crosstalk.

-

Power Distribution: Ensure that power is efficiently distributed to all components, using dedicated power planes or wide traces to minimize voltage drops.

-

Grounding: Implement a solid grounding scheme, using ground planes and proper grounding techniques to minimize noise and ensure signal integrity.

Manufacturing and Assembly of PCB for Wired Printing Head

PCB Fabrication Process

The PCB fabrication process involves several steps, including:

-

PCB Design: The PCB layout is designed using specialized software, such as Altium Designer or KiCad.

-

Gerber File Generation: The PCB design is exported as Gerber files, which are industry-standard files used for PCB fabrication.

-

PCB Manufacturing: The Gerber files are sent to a PCB manufacturer, who creates the physical PCB using processes like etching, drilling, and plating.

-

Solder Mask Application: A solder mask is applied to the PCB to protect the copper traces and prevent short circuits during soldering.

-

Silkscreen Printing: A silkscreen layer is printed on the PCB to provide component labels and other important information.

PCB Assembly Techniques

Once the PCB is fabricated, the components need to be assembled onto the board. There are two primary assembly techniques:

-

Through-Hole Assembly: Components with long leads are inserted through holes drilled in the PCB and soldered on the opposite side.

-

Surface Mount Assembly: Components are placed directly on the surface of the PCB and soldered using techniques like reflow soldering or wave soldering.

| Assembly Technique | Advantages | Disadvantages |

|---|---|---|

| Through-Hole | – Strong mechanical connection | – Larger component size |

| – Easier manual assembly | – Higher manufacturing costs | |

| Surface Mount | – Smaller component size | – Requires specialized assembly equipment |

| – Higher component density | – More sensitive to thermal stress |

Testing and Quality Control

After the PCB is assembled, it undergoes rigorous testing and quality control procedures to ensure proper functionality and reliability. Some common tests include:

-

Visual Inspection: The PCB is visually inspected for any manufacturing defects, such as poor soldering or damaged components.

-

Electrical Testing: The PCB is subjected to various electrical tests, such as continuity tests, insulation resistance tests, and functional tests, to verify its electrical performance.

-

Environmental Testing: The PCB may be exposed to extreme temperatures, humidity, or vibrations to assess its durability and reliability under different environmental conditions.

-

Burn-In Testing: The PCB is operated continuously for an extended period to identify any early failures or stability issues.

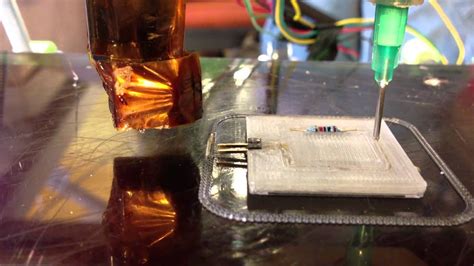

Integrating PCB with Wired Printing Head

Connecting PCB to Printing Head

The PCB is connected to the wired printing head using a combination of connectors and wires. Some common connection methods include:

-

Ribbon Cables: Flat, flexible cables that contain multiple conductors arranged in a side-by-side manner. They are commonly used for connecting PCBs to other components or subsystems.

-

Crimp Connectors: Connectors that use a crimping mechanism to securely attach wires to the connector pins. They provide a reliable and robust connection between the PCB and the printing head.

-

Soldered Connections: In some cases, wires may be directly soldered to the PCB or the printing head components for a permanent connection.

Firmware Development

The PCB for the wired printing head requires firmware to control its functions and communicate with the Fabtotum printer’s main control board. The firmware is typically developed using programming languages like C or C++ and is flashed onto the microcontroller on the PCB.

The firmware handles various tasks, such as:

-

Stepper Motor Control: Generating step and direction signals to control the movement of the stepper motors that drive the printing head.

-

Temperature Regulation: Monitoring and controlling the temperature of the printing head using sensors and heater cartridges.

-

Communication: Establishing communication with the main control board to receive commands and send status updates.

-

Safety Features: Implementing safety features, such as thermal runaway protection or filament detection, to prevent damage to the printing head or the printer.

Calibration and Fine-tuning

After the PCB is integrated with the wired printing head, the assembly needs to be calibrated and fine-tuned for optimal performance. This process involves:

-

Stepper Motor Calibration: Adjusting the stepper motor drivers to ensure accurate and smooth movement of the printing head.

-

Temperature Calibration: Calibrating the temperature sensor and heater cartridge to maintain precise temperature control during printing.

-

Filament Extrusion: Fine-tuning the filament extrusion settings, such as flow rate and retraction, to achieve consistent and high-quality prints.

-

Mechanical Alignment: Ensuring proper alignment of the printing head with respect to the printer’s build platform and axis.

Maintenance and Troubleshooting

Regular Maintenance

To ensure the longevity and performance of the PCB and wired printing head, regular maintenance is essential. Some maintenance tasks include:

-

Cleaning: Regularly clean the printing head and the PCB to remove any dust, debris, or residual filament that may accumulate over time.

-

Inspection: Periodically inspect the PCB and the printing head for any signs of wear, damage, or loose connections.

-

Firmware Updates: Keep the firmware up to date to benefit from bug fixes, performance improvements, and new features.

-

Lubrication: Lubricate moving parts, such as linear bearings or lead screws, to maintain smooth and efficient motion.

Common Issues and Troubleshooting

Despite proper maintenance, issues may arise with the PCB or the wired printing head. Some common problems and their troubleshooting steps include:

| Issue | Troubleshooting Steps |

|---|---|

| No power to the PCB | – Check power connections and supply voltage |

| – Inspect the PCB for any visible damage or short circuits | |

| Stepper motors not moving | – Verify stepper driver connections and configuration |

| – Check for any mechanical obstructions or binding | |

| Temperature not reaching | – Ensure proper connection of the temperature sensor |

| set point | – Verify heater cartridge continuity and resistance |

| Poor print quality | – Check filament extrusion settings and nozzle temperature |

| – Inspect the printing head for any clogs or damage |

When troubleshooting, always refer to the manufacturer’s documentation and follow proper safety precautions to avoid any damage to the PCB, printing head, or the printer.

Future Developments and Trends

Advancements in PCB Technology

As PCB technology continues to evolve, we can expect to see several advancements that may benefit the wired printing head in Fabtotum printers:

-

Embedded Components: PCBs with embedded components, such as resistors or capacitors, can reduce the overall size of the PCB and improve its performance.

-

High-Density Interconnect (HDI): HDI PCBs offer higher component density and finer trace widths, enabling more compact and feature-rich designs.

-

Flexible and Stretchable PCBs: The development of flexible and stretchable PCBs may allow for more versatile and conformable printing head designs.

-

Improved Thermal Management: Advancements in PCB materials and thermal management techniques can help dissipate heat more effectively, enhancing the performance and reliability of the printing head.

Integration with Other Technologies

The PCB for the wired printing head can be further enhanced by integrating it with other technologies, such as:

-

Wireless Communication: Incorporating wireless communication modules, such as Wi-Fi or Bluetooth, can enable remote monitoring and control of the printing head.

-

Sensors: Integrating additional sensors, such as filament runout sensors or flow sensors, can provide better feedback and control over the printing process.

-

Artificial Intelligence: Applying AI algorithms to the data collected from the PCB and the printing head can enable predictive maintenance, anomaly detection, and print quality optimization.

As the 3D printing industry continues to grow and evolve, we can expect to see more innovations in PCB design and integration for wired printing heads, leading to improved performance, reliability, and user experience.

Frequently Asked Questions (FAQ)

-

What is the purpose of a PCB in a wired printing head?

A PCB in a wired printing head serves as the control center for the printing head, housing and connecting various electronic components that regulate its functions, such as stepper motor control, temperature regulation, and communication with the main control board. -

What are the advantages of using a PCB in a wired printing head?

Using a PCB in a wired printing head offers several advantages, including a compact design, reliable connections, efficient heat management, and customization options. PCBs enable the organized arrangement of components, reduce wiring issues, and can be tailored to meet specific requirements of the Fabtotum printer. -

What materials are commonly used for PCBs in wired printing heads?

The most common materials used for PCBs in wired printing heads are FR-4, a glass-reinforced epoxy laminate, and aluminum, which offers superior heat dissipation properties. Flexible PCBs made from materials like Kapton or Polyimide can also be used in applications that require the PCB to conform to a specific shape or withstand repeated flexing. -

What are the key considerations when designing a PCB for a wired printing head?

When designing a PCB for a wired printing head, key considerations include choosing the appropriate PCB material, determining the layer stack-up, optimizing component placement and routing, implementing efficient power distribution, and ensuring proper grounding. These factors contribute to the overall performance, reliability, and functionality of the PCB. -

How can I troubleshoot common issues with the PCB or wired printing head?

To troubleshoot common issues with the PCB or wired printing head, first identify the specific problem, such as lack of power, stepper motors not moving, or poor print quality. Then, follow the appropriate troubleshooting steps, which may include checking connections, inspecting the PCB for damage, verifying component configurations, and examining the printing head for clogs or damage. Always refer to the manufacturer’s documentation and follow proper safety precautions when troubleshooting.

No responses yet