Introduction to Custom Keyboard PCBs

Custom mechanical keyboards have gained immense popularity among enthusiasts and professionals alike. At the heart of every custom keyboard lies a printed circuit board (PCB) that serves as the foundation for all the components. In this comprehensive article, we’ll dive deep into the world of keyboard PCBs, exploring their functions, types, and the step-by-step process of building your own custom mechanical keyboard.

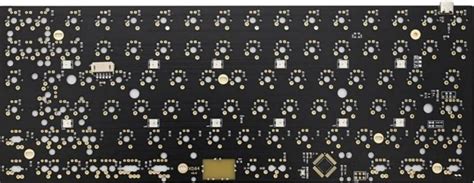

What is a Keyboard PCB?

A keyboard PCB is a printed circuit board that acts as the brain of a mechanical keyboard. It houses the key switches, microcontroller, and other electronic components necessary for the keyboard to function. The PCB is responsible for registering key presses, sending signals to the computer, and controlling various features such as LED lighting and programmable macros.

Functions of a Keyboard PCB

-

Switch Mounting: The PCB provides a platform for mounting the key switches, ensuring precise and stable positioning.

-

Electrical Connectivity: Copper traces on the PCB connect the key switches to the microcontroller, enabling the transmission of electrical signals when a key is pressed.

-

Microcontroller Integration: The PCB houses the microcontroller, which is the central processing unit of the keyboard. It interprets the key presses and sends the corresponding signals to the computer.

-

LED Lighting: Many custom keyboard PCBs support LED lighting, allowing users to customize the backlight or underglow of their keyboard.

-

Programmability: Some PCBs come with programmable firmware, enabling users to remap keys, create macros, and customize the keyboard’s behavior.

Types of Keyboard PCBs

When building a custom mechanical keyboard, you have several options for choosing a PCB. Here are the main types of keyboard PCBs:

1. Pre-designed PCBs

Pre-designed PCBs are ready-made boards that are compatible with specific keyboard layouts and form factors. They often come with pre-soldered components and are easier to work with for beginners. Examples of pre-designed PCBs include:

- 60% PCBs (e.g., GH60, DZ60)

- 65% PCBs (e.g., KBD65, Tada68)

- 75% PCBs (e.g., KBD75, XD84)

- TKL PCBs (e.g., Phantom, Filco)

- Full-size PCBs (e.g., Winkeyless B.87, Phantom TKL)

2. Custom-designed PCBs

For those with more advanced skills or specific requirements, custom-designed PCBs offer complete control over the keyboard’s layout, features, and aesthetics. Designing a custom PCB involves using PCB design software, such as KiCad or Eagle, to create the schematic and layout of the board.

Custom-designed PCBs allow for unique layouts, unconventional key placements, and the integration of additional features like rotary encoders or OLED displays.

Building a Custom Mechanical Keyboard with a PCB

Now that we’ve covered the basics of keyboard PCBs, let’s walk through the process of building a custom mechanical keyboard using a PCB.

Step 1: Choose Your PCB

Select a PCB that suits your desired keyboard layout and features. Consider factors such as compatibility with your preferred key switches, LED lighting support, and programmability.

Step 2: Gather the Components

In addition to the PCB, you’ll need the following components:

- Key switches

- Keycaps

- Stabilizers (for larger keys like the spacebar)

- Case or plate

- USB cable

- Soldering iron and solder

- (Optional) LED lights

Step 3: Prepare the PCB

If your PCB doesn’t come with pre-soldered components, you’ll need to solder the necessary components onto the board. This typically includes:

- Diodes (one for each switch)

- Resistors (for LED lighting, if applicable)

- Microcontroller

- USB port

Refer to the PCB’s documentation for the specific soldering requirements and component placement.

Step 4: Install the Stabilizers

Before soldering the switches, install the stabilizers for the larger keys (e.g., spacebar, enter, shift). Stabilizers help ensure a smooth and even key press for these larger keys.

Step 5: Solder the Switches

Place the switches into the designated spots on the PCB and solder them in place. Ensure that the switches are properly aligned and seated before soldering.

Step 6: Assemble the Keyboard

Once all the switches are soldered, assemble the keyboard by placing the PCB into the case or mounting it onto the plate. Secure the PCB with screws or the provided mounting mechanism.

Step 7: Flash the Firmware

If your PCB supports programmability, you’ll need to flash the firmware onto the microcontroller. This process varies depending on the specific PCB and firmware you’re using. Popular firmware options include QMK and TMK.

Step 8: Test and Customize

After flashing the firmware, test your keyboard to ensure all keys are functioning properly. You can now customize the keyboard’s layout, macros, and lighting effects using the firmware’s configuration files or software.

Frequently Asked Questions (FAQ)

-

Q: Can I use any key switches with a keyboard PCB?

A: Not all key switches are compatible with every PCB. Make sure to choose switches that are compatible with your specific PCB, such as Cherry MX, Gateron, or Kailh switches. -

Q: Do I need to solder the components myself?

A: It depends on the PCB you choose. Some PCBs come with pre-soldered components, while others require you to solder them yourself. If you’re not comfortable with soldering, opt for a PCB with pre-soldered components or seek assistance from someone with soldering experience. -

Q: Can I customize the layout of my keyboard?

A: Yes, many keyboard PCBs support customization of the layout through firmware like QMK or TMK. You can remap keys, create macros, and define your own layout to suit your preferences. -

Q: What is the difference between a hotswap PCB and a regular PCB?

A: A hotswap PCB allows you to install and remove switches without soldering. It features sockets that the switch pins can be inserted into, making it easier to swap out switches. Regular PCBs require switches to be soldered directly onto the board. -

Q: How do I troubleshoot issues with my custom keyboard?

A: If you encounter issues with your custom keyboard, first check the soldering joints and ensure all components are properly connected. Make sure the firmware is correctly flashed and configured. If the problem persists, consult the documentation or seek support from the keyboard community forums or the PCB manufacturer.

Conclusion

Building a custom mechanical keyboard with a PCB is a rewarding and enjoyable experience for keyboard enthusiasts. By understanding the functions and types of keyboard PCBs, and following the step-by-step build process, you can create a personalized keyboard that suits your unique needs and preferences.

Whether you choose a pre-designed PCB or venture into custom PCB design, the possibilities for customization are endless. With the right knowledge and tools, you can build a high-quality, bespoke mechanical keyboard that reflects your style and enhances your typing experience.

No responses yet