What is PCB design?

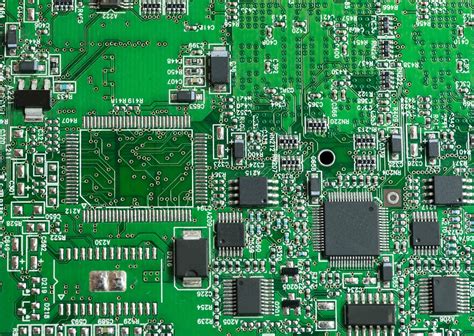

PCB design, short for Printed Circuit Board design, is the process of creating the layout and design of electronic circuits on a printed circuit board. It involves determining the placement of components, routing of traces, and creation of the final artwork that will be used to manufacture the physical board.

PCB design is a crucial step in the development of electronic devices, as it directly impacts the functionality, reliability, and manufacturability of the final product. A well-designed PCB ensures that the electronic components are properly connected, signal integrity is maintained, and the board can withstand the intended operating conditions.

The PCB Design Process

The PCB design process typically involves the following steps:

-

Schematic Design: The first step is to create a schematic diagram that represents the electrical connections between components. This is done using electronic design automation (EDA) software.

-

Component Placement: Once the schematic is complete, the components are placed on the board layout. The placement is optimized for signal integrity, manufacturability, and ease of assembly.

-

Routing: After component placement, the traces that connect the components are routed. This is done using EDA software, which automatically routes the traces based on design rules and constraints.

-

Design Rule Check (DRC): A DRC is performed to ensure that the design meets the manufacturing specifications and design rules. This includes checking for minimum trace widths, spacing, and other parameters.

-

Gerber File Generation: Once the design is finalized, Gerber files are generated. These files contain the information needed to manufacture the PCB, including the copper layers, solder mask, and silkscreen.

The Importance of PCB Design

PCB design is a critical aspect of electronic product development. A well-designed PCB can provide numerous benefits, including:

Improved Functionality

A properly designed PCB ensures that the electronic components are connected correctly and that the circuit functions as intended. This is achieved through careful component placement, signal routing, and adherence to design rules.

Increased Reliability

A well-designed PCB is more reliable and less prone to failure. This is because the design takes into account factors such as signal integrity, thermal management, and mechanical stress. By addressing these issues during the design phase, the final product is more robust and reliable.

Cost Reduction

Effective PCB design can help reduce manufacturing costs. By optimizing the board layout for manufacturability, the production process becomes more efficient, reducing the time and resources required. Additionally, a well-designed PCB minimizes the chances of manufacturing defects, which can lead to costly rework or scrap.

Miniaturization

PCB design plays a crucial role in the miniaturization of electronic devices. As consumer demand for smaller and more compact products increases, PCB designers must find ways to fit more components and functionality into smaller board sizes. Advanced PCB design techniques, such as high-density interconnect (HDI) and multi-layer boards, enable the creation of highly miniaturized devices.

Faster Time-to-Market

A streamlined PCB design process can significantly reduce the time required to bring a product to market. By using EDA software and following best practices, designers can create and revise PCB layouts quickly and efficiently. This allows for faster prototyping, testing, and final production, giving companies a competitive edge in the market.

PCB Design Challenges

While PCB design offers many benefits, it also presents several challenges that designers must overcome:

Signal Integrity

Maintaining signal integrity is a critical challenge in PCB design. As the speed and frequency of electronic devices increase, the potential for signal degradation and interference also rises. Designers must carefully consider factors such as trace routing, impedance matching, and crosstalk to ensure that signals remain clean and stable.

Thermal Management

Electronic components generate heat during operation, and excessive heat can lead to performance issues and even failure. PCB designers must incorporate thermal management techniques, such as proper component placement, use of thermal vias, and heatsinks, to dissipate heat effectively and keep the board within acceptable temperature ranges.

Electromagnetic Compatibility (EMC)

Ensuring electromagnetic compatibility is another challenge in PCB design. Electronic devices must not emit excessive electromagnetic interference (EMI) that could disrupt other devices, and they must also be immune to external EMI. Designers must follow EMC guidelines, use appropriate shielding and grounding techniques, and conduct EMC testing to ensure compliance with regulations.

Manufacturing Constraints

PCB designers must also consider manufacturing constraints when creating board layouts. Different manufacturing processes have specific design rules and limitations that must be adhered to. For example, minimum trace widths, spacing, and hole sizes may vary depending on the manufacturing technology used. Designers must work closely with manufacturers to ensure that the PCB design is compatible with their processes and capabilities.

The Future of PCB Design

As technology continues to advance, the field of PCB design is also evolving. Some of the trends and developments shaping the future of PCB design include:

Advanced Materials

New materials are being developed to improve the performance and reliability of PCBs. For example, high-frequency laminates with low dielectric loss are being used to support faster signal speeds and reduce signal distortion. Flexible and stretchable materials are also gaining traction for wearable and IoT applications.

3D Printing

3D printing technology is being explored for PCB fabrication. This approach allows for the creation of complex 3D structures and the integration of electronics directly into mechanical parts. 3D-printed PCBs have the potential to enable new design possibilities and reduce the size and weight of electronic devices.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are being applied to PCB design to automate and optimize the design process. These technologies can help designers make informed decisions, identify potential issues early in the design cycle, and generate optimized layouts based on specific constraints and objectives.

Collaborative Design

Cloud-based PCB design platforms are enabling greater collaboration among design teams. These platforms allow multiple designers to work on the same project simultaneously, regardless of their location. Collaborative design tools also facilitate version control, design review, and data management, streamlining the overall design process.

Frequently Asked Questions (FAQ)

1. What skills are required for PCB design?

To be successful in PCB design, one should have a strong understanding of electronic circuits, component characteristics, and PCB manufacturing processes. Proficiency in EDA software, such as Altium Designer, Cadence OrCAD, or KiCad, is also essential. Additionally, knowledge of signal integrity, EMC, and thermal management principles is valuable.

2. How long does it take to learn PCB design?

The time required to learn PCB design varies depending on an individual’s background and dedication. Those with a solid foundation in electronics and computer-aided design (CAD) may grasp the basics more quickly. Generally, it can take several months to a year of consistent practice and learning to become proficient in PCB design.

3. Is PCB design a good career?

Yes, PCB design is a promising career path. As electronic devices continue to proliferate in various industries, the demand for skilled PCB designers remains high. PCB designers can find opportunities in sectors such as consumer electronics, automotive, aerospace, medical devices, and telecommunications.

4. What is the average salary for a PCB designer?

The salary of a PCB designer varies based on factors such as experience, location, and industry. According to data from PayScale, the average annual salary for a PCB designer in the United States is around $65,000. However, experienced designers in high-demand industries can earn significantly more.

5. What is the difference between a schematic and a PCB layout?

A schematic is a graphical representation of an electronic circuit that shows the electrical connections between components using symbols. It focuses on the logical design of the circuit. On the other hand, a PCB layout is the physical representation of the circuit on a printed circuit board. It shows the actual placement of components, routing of traces, and other physical features of the board.

Conclusion

PCB design is a vital aspect of electronic product development that directly impacts the functionality, reliability, and manufacturability of the final product. It offers numerous benefits, such as improved functionality, increased reliability, cost reduction, miniaturization, and faster time-to-market. However, PCB designers must also overcome challenges related to signal integrity, thermal management, EMC, and manufacturing constraints.

As technology advances, the field of PCB design is evolving, with trends such as advanced materials, 3D printing, AI and ML, and collaborative design shaping its future. The demand for skilled PCB designers remains strong, making it a promising career path for those with a passion for electronics and design.

To excel in PCB design, individuals should develop a strong foundation in electronic circuits, gain proficiency in EDA software, and stay updated with the latest industry trends and best practices. By mastering the art and science of PCB design, designers can contribute to the creation of innovative and reliable electronic products that shape our world.

| Aspect | Description |

|---|---|

| Functionality | A well-designed PCB ensures that the electronic components are connected correctly and the circuit functions as intended. |

| Reliability | Proper PCB design takes into account factors such as signal integrity, thermal management, and mechanical stress for increased reliability. |

| Cost Reduction | Optimizing the board layout for manufacturability leads to more efficient production, reducing time and resources required. |

| Miniaturization | Advanced PCB design techniques enable the creation of highly miniaturized devices to meet the demand for smaller and more compact products. |

| Faster Time-to-Market | A streamlined PCB design process, using EDA software and best practices, reduces the time required to bring a product to market. |

In summary, PCB design is a critical and rewarding field that plays a crucial role in the development of electronic devices. Its importance, challenges, and future prospects make it a worthwhile endeavor for those seeking a career in electronics and design.

No responses yet