What is Thermal Insulation?

Thermal insulation is the process of reducing heat transfer between objects or environments with different temperatures. Materials that have low thermal conductivity are considered thermal insulators. These materials minimize the flow of heat, helping to maintain the desired temperature in a specific area or object. Common examples of thermal insulators include air, foam, fiberglass, and certain plastics.

Thermal Properties of FR4

To understand whether FR4 is a thermal insulator, let’s examine its thermal properties:

Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. It is expressed in watts per meter-kelvin (W/mK). Materials with low thermal conductivity are considered good thermal insulators, while those with high thermal conductivity are good thermal conductors. The thermal conductivity of FR4 is approximately 0.3 W/mK, which is relatively low compared to many other materials used in electronics.

| Material | Thermal Conductivity (W/mK) |

|---|---|

| FR4 | 0.3 |

| Aluminum | 205 |

| Copper | 401 |

| Glass | 1.05 |

| Air | 0.024 |

As seen in the table above, FR4 has a much lower thermal conductivity than metals like aluminum and copper, which are commonly used as heat sinks in electronics. This suggests that FR4 is a better thermal insulator than these metals.

Specific Heat Capacity

Specific heat capacity is the amount of heat required to raise the temperature of one gram of a material by one degree Celsius. It is expressed in joules per gram-kelvin (J/gK). Materials with high specific heat capacity can absorb more heat before their temperature rises significantly. The specific heat capacity of FR4 is around 1.1 J/gK, which is relatively high compared to many metals.

| Material | Specific Heat Capacity (J/gK) |

|---|---|

| FR4 | 1.1 |

| Aluminum | 0.897 |

| Copper | 0.385 |

| Glass | 0.84 |

| Air | 1.005 |

The high specific heat capacity of FR4 means that it can absorb a significant amount of heat before its temperature rises, further contributing to its thermal insulation properties.

Thermal Expansion Coefficient

The thermal expansion coefficient is a measure of how much a material expands or contracts when subjected to temperature changes. It is expressed in units of per degree Celsius (1/°C). Materials with low thermal expansion coefficients are more dimensionally stable when exposed to temperature fluctuations. FR4 has a relatively low thermal expansion coefficient of approximately 15 ppm/°C (parts per million per degree Celsius).

| Material | Thermal Expansion Coefficient (ppm/°C) |

|---|---|

| FR4 | 15 |

| Aluminum | 23.1 |

| Copper | 16.5 |

| Glass | 8.5 |

| Air | 3400 |

The low thermal expansion coefficient of FR4 means that it maintains its dimensional stability when subjected to temperature changes, which is important for maintaining the integrity of PCBs and preventing warping or cracking.

Applications of FR4 Insulation

FR4’s thermal insulation properties make it suitable for various applications in the electronics industry:

-

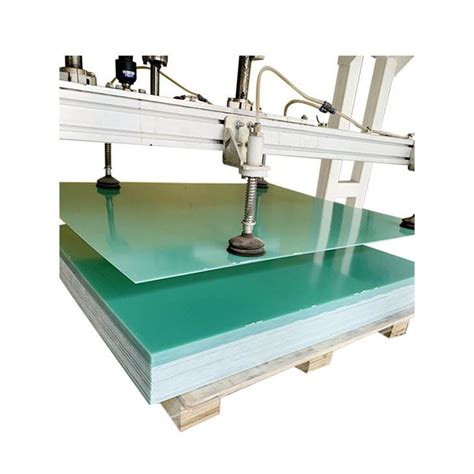

Printed Circuit Boards (PCBs): FR4 is the most common material used for PCBs due to its excellent electrical insulation and thermal stability. Its low thermal conductivity helps to prevent the transfer of heat between components on the PCB, reducing the risk of thermal damage.

-

Insulating Washers and Spacers: FR4 washers and spacers are used to provide thermal insulation between components and heat sinks in electronic devices. They help to minimize heat transfer and maintain the desired operating temperature of the components.

-

High-Temperature Applications: FR4 can withstand temperatures up to 140°C continuously and 170°C for short periods. This makes it suitable for use in high-temperature environments, such as in automotive and aerospace electronics.

-

Thermal Interface Materials (TIMs): FR4 can be used as a thermal interface material between heat-generating components and heat sinks. Although it is not as effective as dedicated TIMs, such as thermal pastes or pads, FR4 can provide some level of thermal insulation in low-power applications.

FAQ

-

Q: Is FR4 a good thermal insulator compared to other materials used in electronics?

A: Yes, FR4 is a good thermal insulator compared to many other materials used in electronics, such as metals like aluminum and copper. Its low thermal conductivity and high specific heat capacity make it an effective thermal insulator. -

Q: Can FR4 be used as a heat sink material?

A: No, FR4 is not suitable as a heat sink material due to its low thermal conductivity. Heat sinks are designed to dissipate heat efficiently, and materials with high thermal conductivity, such as aluminum or copper, are better suited for this purpose. -

Q: What is the maximum operating temperature for FR4?

A: FR4 can withstand temperatures up to 140°C continuously and 170°C for short periods. However, prolonged exposure to temperatures above 140°C can cause the material to degrade and lose its mechanical and electrical properties. -

Q: How does the thermal expansion coefficient of FR4 compare to other materials?

A: FR4 has a relatively low thermal expansion coefficient compared to many other materials used in electronics. This means that it maintains its dimensional stability when subjected to temperature changes, which is important for maintaining the integrity of PCBs and preventing warping or cracking. -

Q: Are there any disadvantages to using FR4 as a thermal insulator?

A: While FR4 is an effective thermal insulator, it is not the best choice for all applications. In high-power applications or situations where efficient heat dissipation is critical, materials with higher thermal conductivity, such as aluminum or copper, may be more suitable. Additionally, FR4 is not as effective as dedicated thermal interface materials, such as thermal pastes or pads, in transferring heat between components and heat sinks.

Conclusion

In conclusion, FR4 is indeed a thermal insulator, thanks to its low thermal conductivity, high specific heat capacity, and low thermal expansion coefficient. These properties make FR4 an excellent choice for various applications in the electronics industry, particularly in the manufacturing of PCBs and as insulating washers and spacers.

However, it is important to note that while FR4 is a good thermal insulator, it is not the best choice for all applications. In situations where efficient heat dissipation is critical, materials with higher thermal conductivity may be more suitable. Nonetheless, FR4’s thermal insulation properties, combined with its excellent mechanical and electrical properties, make it a versatile and widely used material in the electronics industry.

No responses yet