Understanding the Basics of Desoldering

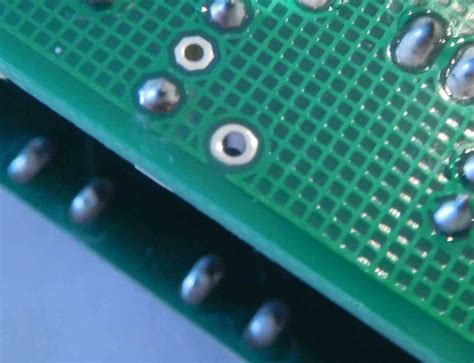

Before diving into the methods of removing solder from a Circuit Board hole, it’s essential to understand the basics of desoldering. Desoldering is the process of removing solder from a joint or hole to separate components or wires from a circuit board. It is the opposite of soldering, which involves melting solder to create an electrical and mechanical connection.

When desoldering, you need to consider several factors:

-

Type of solder: Different types of solder have varying melting points and properties. Lead-based solder, for example, has a lower melting point than lead-free solder.

-

Temperature: To effectively melt the solder, you need to apply the appropriate temperature. Overheating can damage the circuit board or components, while insufficient heat may not melt the solder properly.

-

Tools and equipment: Having the right tools and equipment is crucial for successful desoldering. These may include a soldering iron, desoldering pump, solder wick, and other specialized tools.

-

Safety: Desoldering involves working with hot tools and molten solder. It’s essential to follow safety precautions, such as wearing protective gear and working in a well-ventilated area.

Tools and Equipment for Desoldering Holes

To effectively remove solder from a circuit board hole, you’ll need the following tools and equipment:

-

Soldering iron: A soldering iron is the primary tool used for desoldering. Choose a soldering iron with adjustable temperature control and a fine tip for precision work.

-

Desoldering pump (solder sucker): A desoldering pump, also known as a solder sucker, is a spring-loaded device that creates suction to remove molten solder from a hole or joint.

-

Solder wick (desoldering braid): Solder wick, also called desoldering braid, is a fine copper braid that absorbs molten solder through capillary action.

-

Tweezers: Tweezers are useful for holding small components or wires while desoldering.

-

Solder: Having some solder on hand can be helpful for adding fresh solder to a joint to improve heat transfer and make desoldering easier.

-

Flux: Flux helps to improve the flow of solder and remove oxidation. You can use liquid flux or flux-cored solder.

-

Safety equipment: Wear safety glasses to protect your eyes from solder splashes and use a fume extractor or work in a well-ventilated area to avoid inhaling solder fumes.

Method 1: Using a Desoldering Pump (Solder Sucker)

A desoldering pump, also known as a solder sucker, is a simple and effective tool for removing solder from a circuit board hole. Here’s how to use it:

-

Heat the solder: Apply the soldering iron tip to the solder in the hole until it melts. Keep the iron in place for a few seconds to ensure the solder is fully molten.

-

Position the desoldering pump: While keeping the soldering iron in place, position the nozzle of the desoldering pump close to the molten solder, but not touching it.

-

Trigger the desoldering pump: Quickly remove the soldering iron and simultaneously trigger the desoldering pump to suck up the molten solder. The solder will be drawn into the pump’s chamber.

-

Clean the tip: After each use, clean the tip of the desoldering pump to remove any residual solder. Most pumps have a built-in plunger that can be pressed to eject the collected solder.

-

Repeat if necessary: If there is still solder remaining in the hole, repeat the process until the hole is clear.

Tips for using a desoldering pump effectively:

- Ensure the pump is primed and ready to use before heating the solder.

- Use a soldering iron with a fine tip to avoid overheating the surrounding area.

- Work quickly to remove the solder while it’s still molten.

- Practice the technique to develop a steady hand and good coordination between the soldering iron and desoldering pump.

Method 2: Using Solder Wick (Desoldering Braid)

Solder wick, also known as desoldering braid, is another popular tool for removing solder from circuit board holes. It works by absorbing molten solder through capillary action. Here’s how to use solder wick:

-

Cut a piece of solder wick: Cut a piece of solder wick that is slightly longer than the hole you want to desolder. If the hole is particularly large or has a lot of solder, you may need a longer piece.

-

Apply flux (optional): If desired, apply a small amount of flux to the solder wick to help improve its efficiency in absorbing solder.

-

Place the solder wick on the hole: Place one end of the solder wick on top of the solder-filled hole, ensuring good contact between the wick and the solder.

-

Heat the solder wick: Touch the soldering iron tip to the top of the solder wick, directly above the hole. Apply gentle pressure and heat until you see the solder melting and being absorbed into the wick.

-

Move the soldering iron and wick: Slowly move the soldering iron and solder wick together along the length of the hole, allowing the wick to absorb the molten solder as you go.

-

Remove the solder wick: Once the solder has been absorbed and the hole is clear, lift the soldering iron and solder wick away from the board.

-

Clean the soldering iron tip: Wipe the soldering iron tip on a damp sponge or brass wool to remove any residual solder or flux.

-

Repeat if necessary: If there is still solder remaining in the hole, cut a new piece of solder wick and repeat the process.

Tips for using solder wick effectively:

- Use a soldering iron with a wide, flat tip to heat the solder wick evenly.

- Apply gentle pressure to ensure good contact between the wick and the solder.

- Work slowly and steadily to allow the wick to absorb the solder.

- If the solder is not melting easily, try adding a small amount of fresh solder to improve heat transfer.

Method 3: Combination of Desoldering Pump and Solder Wick

In some cases, using a combination of a desoldering pump and solder wick can be the most effective approach to remove solder from a circuit board hole. This method is particularly useful for holes with a large amount of solder or hard-to-reach areas. Here’s how to combine these tools:

-

Heat the solder: Apply the soldering iron tip to the solder in the hole until it melts. Keep the iron in place for a few seconds to ensure the solder is fully molten.

-

Use the desoldering pump: While keeping the soldering iron in place, position the nozzle of the desoldering pump close to the molten solder and trigger it to suck up as much solder as possible.

-

Remove the remaining solder with solder wick: If there is still solder remaining in the hole, cut a piece of solder wick and place it on top of the hole. Heat the wick with the soldering iron and allow it to absorb the remaining solder.

-

Repeat if necessary: If the hole is not completely clear, repeat the process, using the desoldering pump and solder wick as needed until all the solder is removed.

Tips for combining desoldering pump and solder wick:

- Start with the desoldering pump to remove the bulk of the solder, then use the solder wick for more precise cleaning.

- Be careful not to overheat the board or components when using both tools.

- Take breaks between attempts to allow the board and components to cool down.

Advanced Desoldering Techniques

In addition to the basic methods described above, there are some advanced techniques and tools that can make desoldering holes even more efficient:

-

Desoldering station: A desoldering station is a professional-grade tool that combines a soldering iron with a built-in vacuum pump. It allows for precise temperature control and efficient solder removal.

-

Hot air rework station: A hot air rework station uses a directed stream of hot air to melt solder and can be useful for desoldering surface-mounted components or multiple pins simultaneously.

-

Chip quik: Chip quik is a specialized low-melting-point alloy that can be used to remove solder from holes or joints. When heated, it mixes with the existing solder, lowering its melting point and making it easier to remove.

-

Soldering iron with built-in vacuum pump: Some soldering irons come with a built-in vacuum pump, allowing you to Desolder holes without the need for a separate desoldering pump.

Troubleshooting Common Desoldering Issues

Despite your best efforts, you may sometimes encounter issues when trying to remove solder from a circuit board hole. Here are some common problems and their solutions:

-

Solder won’t melt: If the solder is not melting, the soldering iron temperature may be too low, or there may be oxidation on the solder’s surface. Increase the iron’s temperature and apply a small amount of flux to help break down the oxidation.

-

Solder won’t come out of the hole: If the solder is melting but won’t come out of the hole, it may be because the hole is clogged with debris or the solder has formed a plug. Use a small drill bit or a needle to clear the debris and create a path for the molten solder to escape.

-

Damage to the circuit board or components: Overheating the board or applying too much pressure can cause damage. Use a soldering iron with temperature control, work quickly, and be gentle when desoldering.

-

Solder wick not absorbing solder: If the solder wick is not absorbing the solder efficiently, it may be due to insufficient heat or poor contact between the wick and the solder. Ensure the soldering iron is hot enough and apply gentle pressure to improve contact.

Safety Precautions and Best Practices

When desoldering holes on a circuit board, it’s essential to prioritize safety and follow best practices to avoid injuries and damage to the equipment. Here are some key safety precautions and best practices:

-

Wear protective gear: Always wear safety glasses to protect your eyes from solder splashes and fumes. Consider wearing gloves to avoid burns from hot tools or molten solder.

-

Work in a well-ventilated area: Solder fumes can be harmful if inhaled in large quantities. Work in a well-ventilated area or use a fume extractor to minimize exposure.

-

Use a soldering iron with temperature control: A soldering iron with adjustable temperature control allows you to set the appropriate heat for the type of solder and components you’re working with, reducing the risk of damage.

-

Keep the soldering iron and tools clean: Regularly clean the soldering iron tip and other tools to ensure optimal performance and prevent contamination.

-

Handle hot tools and molten solder with care: Always be mindful that the soldering iron and molten solder are extremely hot. Avoid touching them directly and place hot tools on a heat-resistant surface when not in use.

-

Take breaks and avoid prolonged exposure: Desoldering can be a time-consuming process. Take breaks to rest your hands and eyes, and avoid prolonged exposure to solder fumes.

-

Dispose of solder and debris properly: Collect any removed solder and debris in a designated container and dispose of it in accordance with local regulations for electronic waste.

Frequently Asked Questions (FAQ)

-

What is the best method for removing solder from a circuit board hole?

The best method for removing solder from a circuit board hole depends on the amount of solder, the size of the hole, and the tools available. For most situations, using a desoldering pump or solder wick, or a combination of both, will be effective. -

Can I use a regular soldering iron for desoldering?

Yes, you can use a regular soldering iron for desoldering, but it’s recommended to use one with adjustable temperature control for better results and to minimize the risk of damage to the board or components. -

How do I prevent damage to the circuit board while desoldering?

To prevent damage to the circuit board while desoldering, use a soldering iron with temperature control, work quickly to avoid overheating, apply gentle pressure, and take breaks to allow the board and components to cool down. -

What should I do if the solder won’t melt or come out of the hole?

If the solder won’t melt, increase the soldering iron temperature and apply a small amount of flux to help break down any oxidation. If the solder won’t come out of the hole, use a small drill bit or needle to clear any debris and create a path for the molten solder to escape. -

How do I dispose of the removed solder and debris?

Collect the removed solder and debris in a designated container and dispose of it in accordance with local regulations for electronic waste. Do not dispose of solder in regular household trash, as it may contain lead or other harmful substances.

Conclusion

Removing solder from a circuit board hole is a crucial skill for anyone working with electronic projects. By understanding the basics of desoldering, having the right tools and equipment, and following the appropriate methods and safety precautions, you can effectively desolder holes and maintain the integrity of your circuit boards. Whether you choose to use a desoldering pump, solder wick, or a combination of both, practice and patience will help you master the technique. Remember to prioritize safety, work in a well-ventilated area, and take breaks as needed. With the knowledge and skills gained from this guide, you’ll be well-equipped to tackle any desoldering task that comes your way.

No responses yet