Introduction to Circuit Boards

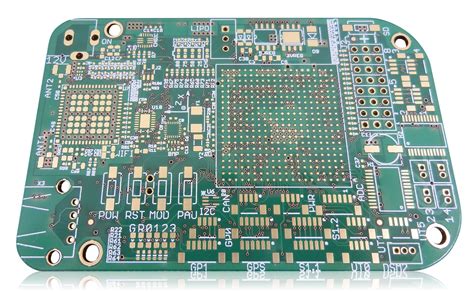

A circuit board, also known as a Printed Circuit Board (PCB), is the backbone of most electronic devices. It is a flat board made of insulating material, such as fiberglass or plastic, with conductive tracks, pads, and other features etched onto the surface. These conductive elements connect various components, such as resistors, capacitors, and integrated circuits, to create a functional electronic circuit.

In this article, we will guide you through the process of drawing a simple circuit board, covering the essential tools, materials, and techniques required to create a basic PCB layout.

Key Components of a Circuit Board

Before we dive into the drawing process, let’s familiarize ourselves with the main components of a circuit board:

| Component | Description |

|---|---|

| Substrate | The insulating base material, typically fiberglass or plastic. |

| Copper Traces | Thin, conductive paths that connect components. |

| Pads | Exposed areas of copper used for soldering components. |

| Vias | Conductive holes that allow traces to connect between layers. |

| Solder Mask | A protective layer that covers the copper traces, leaving only the pads exposed. |

| Silkscreen | Text and symbols printed on the PCB for identification and assembly purposes. |

Tools and Materials Required

To draw a simple circuit board, you’ll need the following tools and materials:

- PCB design software (e.g., KiCad, Eagle, or Altium Designer)

- Computer with sufficient processing power and memory

- Schematic diagram of your circuit

- Component footprint libraries (usually included with the PCB design software)

- Ruler or measuring tool

- Pencil and eraser

- Grid paper (optional)

Step-by-Step Guide to Drawing a Simple Circuit Board

Step 1: Create a Schematic Diagram

Before starting the PCB layout, you must have a clear understanding of your circuit’s schematic diagram. The schematic represents the logical connections between components using standardized symbols. If you haven’t already created a schematic, use your PCB design software to draw one, ensuring that all components and their connections are accurately represented.

Step 2: Set Up Your PCB Design Software

Open your chosen PCB design software and create a new project. Most software will prompt you to select the board size, number of layers, and other parameters. For a simple circuit board, a two-layer board (top and bottom) is usually sufficient. Set the grid size to a suitable value, such as 0.1 inches or 2.54 mm, to ensure proper alignment of components and traces.

Step 3: Place Components

Import your schematic into the PCB design software. The software will typically generate a list of components and their footprints. Place the components on the board, considering factors such as:

- Logical grouping of related components

- Minimizing the distance between connected components

- Ensuring adequate spacing for heat dissipation and assembly

- Avoiding physical interference between components

Step 4: Route the Traces

Once the components are placed, it’s time to route the traces. Follow these guidelines:

- Use the appropriate trace width based on the current carrying requirements of your circuit. Wider traces can handle higher currents.

- Minimize the length of traces to reduce resistance and inductance.

- Avoid sharp angles or 90-degree turns, as they can cause signal reflections. Use 45-degree angles or curves instead.

- Maintain sufficient clearance between traces to prevent short circuits and signal interference.

- Use vias to connect traces between layers when necessary.

Step 5: Add Power and Ground Planes

For improved power distribution and noise reduction, add power and ground planes to your circuit board. These planes are typically solid copper areas on separate layers, connected to the power and ground traces through vias. Ensure that the planes have adequate clearance around the component pads and Mounting holes.

Step 6: Apply Solder Mask and Silkscreen

Once the traces and planes are in place, apply the solder mask and silkscreen layers. The solder mask protects the copper traces from oxidation and prevents accidental short circuits during soldering. The silkscreen layer adds text and symbols for component identification and assembly instructions.

Step 7: Review and Revise

Before finalizing your design, thoroughly review the circuit board layout for any errors or potential improvements. Check for:

- Proper connectivity between components

- Adequate clearance and spacing

- Correct component orientation and footprints

- Compliance with design rules and manufacturing constraints

Make any necessary revisions and repeat the review process until you are satisfied with the layout.

Step 8: Generate Manufacturing Files

Once your design is complete, generate the necessary manufacturing files, such as Gerber files and drill files. These files contain the information needed by PCB manufacturers to fabricate your circuit board. Most PCB design software has built-in tools for generating these files.

Tips for Successful PCB Layout

- Keep your design simple and modular, breaking complex circuits into smaller, manageable sections.

- Use consistent naming conventions for components, nets, and layers to avoid confusion.

- Follow the design rules and guidelines provided by your PCB manufacturer to ensure manufacturability.

- Consider the mechanical aspects of your design, such as component height and mounting hole placement.

- Use simulation tools, if available, to validate your design before manufacturing.

Frequently Asked Questions (FAQ)

1. What is the difference between a schematic and a PCB layout?

A schematic is a logical representation of a circuit, showing the components and their connections using standardized symbols. A PCB layout, on the other hand, is the physical representation of the circuit, depicting the actual placement of components and routing of traces on a circuit board.

2. Can I design a circuit board without using PCB design software?

While it is possible to design a simple circuit board manually using grid paper and a pencil, it is highly recommended to use PCB design software for more complex designs. PCB design software provides powerful tools for component placement, trace routing, and design rule checking, which can save time and prevent errors.

3. What factors should I consider when choosing the substrate material for my circuit board?

The choice of substrate material depends on several factors, such as:

- Electrical properties (Dielectric constant, loss tangent)

- Mechanical properties (strength, flexibility, thermal expansion)

- Environmental factors (temperature range, humidity, chemical exposure)

- Cost and availability

Common substrate materials include FR-4 (fiberglass), polyimide, and PTFE (Teflon).

4. How do I determine the appropriate trace width for my circuit?

The trace width depends on the current carrying requirements of your circuit. Wider traces can handle higher currents without overheating. Most PCB design software includes tools for calculating the appropriate trace width based on the current, temperature rise, and Copper thickness. Additionally, consult your PCB manufacturer’s design guidelines for recommended trace widths.

5. What are some common mistakes to avoid when designing a circuit board?

Some common mistakes to avoid when designing a circuit board include:

- Failing to consider manufacturability and assembly requirements

- Neglecting to properly route power and ground traces

- Ignoring signal integrity issues, such as crosstalk and reflections

- Not adhering to design rules and guidelines provided by the PCB manufacturer

- Overlooking thermal management and heat dissipation requirements

By following best practices and carefully reviewing your design, you can minimize the risk of these mistakes and ensure a successful PCB layout.

Conclusion

Drawing a simple circuit board involves a systematic approach, from creating a schematic diagram to generating manufacturing files. By understanding the key components, using appropriate tools and materials, and following a step-by-step process, you can create a functional and reliable PCB layout.

Remember to keep your design simple, adhere to best practices, and thoroughly review your work to catch any errors or potential improvements. With practice and attention to detail, you’ll be able to design increasingly complex circuit boards and bring your electronic projects to life.

No responses yet