Understanding the Key Differences in Wave and Reflow Soldering Processes

When it comes to assembling printed circuit boards (PCBs), there are two primary soldering methods used in the electronics manufacturing industry: wave soldering and reflow soldering. While both techniques aim to create reliable electrical connections between components and the PCB, they differ in their processes, applications, and the types of components they can accommodate. In this article, we will explore the distinctive features of wave soldering and reflow soldering, helping you understand when to use each method and how to optimize your PCB Assembly process.

Table of Contents

- Introduction to Soldering

- Wave Soldering

- The Wave Soldering Process

- Advantages of Wave Soldering

- Disadvantages of Wave Soldering

- Reflow Soldering

- The Reflow Soldering Process

- Advantages of Reflow Soldering

- Disadvantages of Reflow Soldering

- Comparing Wave Soldering and Reflow Soldering

- Component Compatibility

- Process Flexibility

- Thermal Profile

- Solder Joint Quality

- Cost and Efficiency

- Choosing the Right Soldering Method

- Factors to Consider

- PCB Design Considerations

- Manufacturing Requirements

- Optimizing Your Soldering Process

- Best Practices for Wave Soldering

- Best Practices for Reflow Soldering

- Quality Control and Inspection

- Frequently Asked Questions (FAQ)

- Conclusion

1. Introduction to Soldering

Soldering is a fundamental process in electronics manufacturing that involves joining two or more metal surfaces by melting a filler metal (solder) to create a strong electrical and mechanical bond. In PCB assembly, soldering is used to attach electronic components to the board, ensuring reliable connections and proper functionality of the circuit.

The two most common soldering methods used in the industry are wave soldering and reflow soldering. Each method has its own unique characteristics, advantages, and limitations, making it crucial to understand their differences to select the most suitable technique for your specific application.

2. Wave Soldering

Wave soldering is a traditional soldering method that has been widely used in the electronics industry for decades. It is particularly well-suited for through-hole components and is known for its ability to handle high-volume production runs efficiently.

The Wave Soldering Process

-

PCB Preparation: The PCB is first cleaned and coated with a thin layer of flux to promote solder wetting and prevent oxidation.

-

Component Placement: Through-hole components are inserted into the designated holes on the PCB, either manually or using automated insertion machines.

-

Preheat: The populated PCB is preheated to activate the flux and minimize thermal shock to the components during the soldering process.

-

Wave Soldering: The preheated PCB is transported over a molten solder wave, which is created by a pump forcing the solder through a nozzle. As the board comes into contact with the wave, the molten solder wets the component leads and the PCB pads, creating a strong solder joint.

-

Cooling and Cleaning: After passing through the solder wave, the PCB is cooled to allow the solder joints to solidify. Any excess flux residue is then cleaned from the board.

Advantages of Wave Soldering

- High-speed process suitable for high-volume production

- Cost-effective for large batches

- Ideal for through-hole components

- Can accommodate larger and heavier components

- Provides good solder joint fillet formation

Disadvantages of Wave Soldering

- Limited compatibility with surface mount devices (SMDs)

- Requires precise control of the solder wave and preheat settings

- Can be prone to defects such as bridging, icicles, and solder shorts

- Difficulty in soldering fine-pitch components

- Higher risk of thermal shock to sensitive components

3. Reflow Soldering

Reflow soldering is a more modern soldering technique that has gained popularity with the increasing use of surface mount technology (SMT) in electronics manufacturing. This method involves applying solder paste to the PCB pads and then heating the entire board to melt the solder, creating a strong bond between the components and the board.

The Reflow Soldering Process

-

PCB Preparation: The PCB is cleaned, and solder paste is applied to the component pads using a stencil or solder paste printer.

-

Component Placement: Surface mount components are placed onto the solder paste-coated pads, either manually or using automated Pick-and-Place machines.

-

Reflow: The populated PCB is passed through a reflow oven, which heats the board according to a predetermined temperature profile. The solder paste melts, wets the component leads and PCB pads, and then solidifies to create a strong solder joint.

-

Cooling and Inspection: After exiting the reflow oven, the PCB is cooled to room temperature, allowing the solder joints to solidify completely. The board is then inspected for any defects or issues.

Advantages of Reflow Soldering

- Ideal for surface mount components

- High precision and accuracy in solder joint formation

- Consistent and repeatable results

- Suitable for high-density PCB designs with fine-pitch components

- Reduced risk of thermal shock to components

- Efficient process for medium to high-volume production

Disadvantages of Reflow Soldering

- Higher initial equipment costs compared to wave soldering

- Limited compatibility with through-hole components

- Requires precise control of the reflow temperature profile

- Solder Paste Printing can be challenging for fine-pitch components

- Potential for voiding in solder joints due to trapped gases

4. Comparing Wave Soldering and Reflow Soldering

To better understand the differences between wave soldering and reflow soldering, let’s compare them across several key factors:

Component Compatibility

| Soldering Method | Through-hole Components | Surface Mount Components |

|---|---|---|

| Wave Soldering | Highly compatible | Limited compatibility |

| Reflow Soldering | Limited compatibility | Highly compatible |

Wave soldering is primarily used for through-hole components, while reflow soldering is best suited for surface mount components. Although some adaptations can be made to accommodate both types of components in each process, it is generally more efficient to use the soldering method that aligns with the dominant component type on the PCB.

Process Flexibility

| Soldering Method | Design Flexibility | Process Control |

|---|---|---|

| Wave Soldering | Moderate | Moderate |

| Reflow Soldering | High | High |

Reflow soldering offers greater design flexibility, as it can easily accommodate high-density PCB layouts with fine-pitch components. It also provides better process control, as the reflow temperature profile can be precisely adjusted to suit the specific requirements of the components and the board. Wave soldering, while still effective, has limitations in terms of design flexibility and process control.

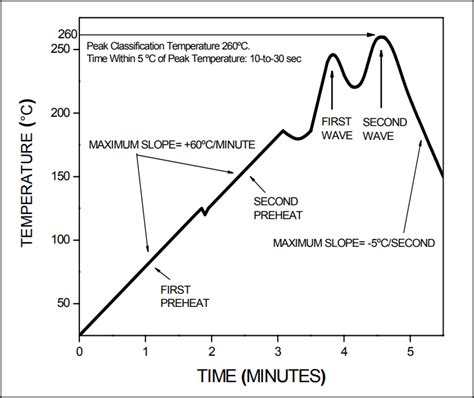

Thermal Profile

| Soldering Method | Preheat Temperature | Peak Temperature | Cooling Rate |

|---|---|---|---|

| Wave Soldering | 80-120°C | 260-280°C | Moderate |

| Reflow Soldering | 150-180°C | 220-250°C | Controlled |

The thermal profiles for wave soldering and reflow soldering differ significantly. Wave soldering typically involves a lower preheat temperature and a higher peak temperature, as the solder wave contact time is brief. Reflow soldering, on the other hand, has a more gradual preheat and a lower peak temperature, as the entire board is heated evenly in the reflow oven. The cooling rate is also more controlled in reflow soldering to minimize thermal stress on the components.

Solder Joint Quality

| Soldering Method | Joint Consistency | Fillet Formation | Voiding Risk |

|---|---|---|---|

| Wave Soldering | Moderate | Good | Low |

| Reflow Soldering | High | Excellent | Moderate |

Reflow soldering generally produces more consistent and higher-quality solder joints compared to wave soldering. The precise control over the reflow temperature profile ensures even heating and cooling, resulting in excellent fillet formation and minimal risk of defects. Wave soldering can produce good fillet formation, but the consistency may vary depending on factors such as wave settings and board design. Reflow soldering has a slightly higher risk of voiding due to trapped gases in the solder paste.

Cost and Efficiency

| Soldering Method | Equipment Cost | Operating Cost | Production Speed |

|---|---|---|---|

| Wave Soldering | Lower | Lower | High |

| Reflow Soldering | Higher | Moderate | Moderate to High |

Wave soldering typically has lower equipment and operating costs compared to reflow soldering, making it a more cost-effective option for high-volume production of through-hole components. Reflow soldering, while having higher initial equipment costs, offers better efficiency and production speed for surface mount components. The choice between the two methods often depends on the specific requirements of the project, such as the component types, board complexity, and production volume.

5. Choosing the Right Soldering Method

Selecting the appropriate soldering method for your PCB assembly project involves considering several factors:

Factors to Consider

-

Component Types: Determine whether your PCB primarily uses through-hole components, surface mount components, or a mix of both.

-

Board Complexity: Assess the complexity of your PCB design, including factors such as component density, pitch, and board size.

-

Production Volume: Consider the expected production volume, as this can impact the cost-effectiveness and efficiency of each soldering method.

-

Quality Requirements: Evaluate the required level of solder joint quality and consistency for your application.

-

Budget and Resources: Factor in your available budget for equipment, operating costs, and skilled personnel.

PCB Design Considerations

When designing your PCB, keep in mind the soldering method you intend to use. For wave soldering, ensure that through-hole components are properly spaced and oriented to allow for efficient soldering and minimize the risk of defects. For reflow soldering, pay attention to the solder paste stencil design, component placement, and reflow temperature profile to achieve optimal results.

Manufacturing Requirements

Work closely with your PCB assembly service provider to discuss your manufacturing requirements and ensure that they have the necessary equipment, expertise, and processes in place to support your chosen soldering method. Provide clear specifications and guidelines to minimize the risk of errors and ensure a smooth production process.

6. Optimizing Your Soldering Process

Regardless of the soldering method you choose, implementing best practices and maintaining a robust quality control system are essential for achieving consistent, high-quality results.

Best Practices for Wave Soldering

- Ensure proper board cleaning and flux application

- Optimize the solder wave height, speed, and temperature

- Use appropriate fixtures and pallets to secure the PCB during soldering

- Regularly monitor and maintain the solder wave system

- Implement effective post-soldering cleaning and inspection processes

Best Practices for Reflow Soldering

- Use high-quality solder paste and maintain proper storage conditions

- Ensure accurate solder paste printing and component placement

- Develop and optimize the reflow temperature profile for your specific components and board

- Regularly calibrate and maintain the reflow oven

- Implement robust inspection and quality control processes

Quality Control and Inspection

Implementing a comprehensive quality control and inspection system is crucial for identifying and addressing any soldering defects or issues. This may include:

- Visual inspection

- Automated optical inspection (AOI)

- X-ray Inspection

- Electrical testing

- Reliability testing

By regularly monitoring and analyzing the results of your quality control processes, you can continuously improve your soldering process and minimize the risk of defects and failures in your final products.

7. Frequently Asked Questions (FAQ)

- Can I use both wave soldering and reflow soldering on the same PCB?

-

Yes, it is possible to use both methods on a single PCB, typically with wave soldering for through-hole components and reflow soldering for surface mount components. However, this may require additional design considerations and process planning.

-

What are some common defects in wave soldering?

-

Common wave soldering defects include bridging, icicles, solder shorts, insufficient fillets, and solder balls.

-

How do I select the right solder paste for reflow soldering?

-

When selecting solder paste, consider factors such as the alloy composition, particle size, flux type, and viscosity. Consult with your solder paste supplier and PCB assembly service provider to choose the most suitable option for your application.

-

Can I reflow solder through-hole components?

-

While it is possible to reflow solder some through-hole components using techniques like pin-in-paste or intrusive reflow, it is generally not recommended for most applications. Wave soldering remains the preferred method for through-hole components.

-

How can I prevent voiding in reflow soldered joints?

- To minimize voiding, optimize your reflow temperature profile, use high-quality solder paste, ensure proper stencil design and paste printing, and consider using vacuum assisted reflow soldering (VARS) for critical components.

8. Conclusion

Understanding the differences between wave soldering and reflow soldering is essential for selecting the most suitable method for your PCB assembly project. By considering factors such as component compatibility, process flexibility, thermal profile, solder joint quality, and cost-efficiency, you can make an informed decision that meets your specific requirements.

Remember to implement best practices and maintain a robust quality control system to optimize your soldering process and ensure consistent, high-quality results. As electronics manufacturing continues to evolve, staying up-to-date with the latest soldering technologies and techniques will help you stay competitive and deliver reliable, high-performance products to your customers.

No responses yet